Wear mitigation method of linear ultrasonic motor and linear ultrasonic motor

A technology of linear ultrasonic motor and piezoelectric element, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical element, etc., can solve the problems of low output power and short service life, etc. Achieve the effects of reducing wear, increasing output force, and reducing environmental sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

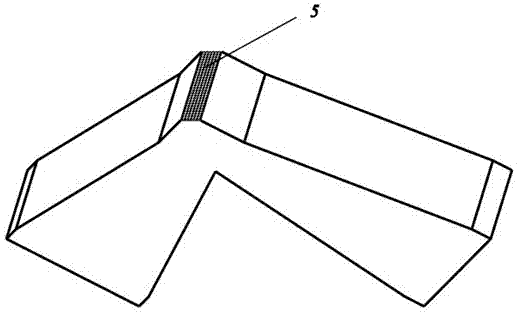

[0033] The inventive idea of the present invention is to apply the surface modification technology to the linear ultrasonic motor, and prepare the pit-shaped surface microstructure on the friction end surface of the stator or the mover, thereby reducing the wear caused by the three-body friction, improving the output force of the motor, output power and service life. In order to facilitate the public's understanding, a V-shaped linear ultrasonic motor is taken as an example below to illustrate the technical solution of the present invention.

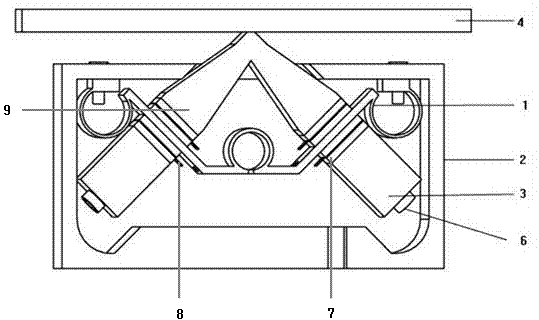

[0034] The structure of the V-shaped linear ultrasonic motor is as attached figure 1 As shown, it includes a stator and a mover 4, wherein the stator is composed of a clamping piece 1, a rear end cover 3, a compression bolt 6, a piezoelectric ceramic 7, an electrode piece 8, a driving foot 9 and other component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com