Supersonic-vibration-assisted micro-milling system

An ultrasonic vibration and micro-milling technology, applied in the direction of fluid, milling machine and milling machine equipment using vibration, can solve the problems of high heat generation, tool wear, low processing efficiency, etc., to reduce tool wear, improve tool life, and improve cutting. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

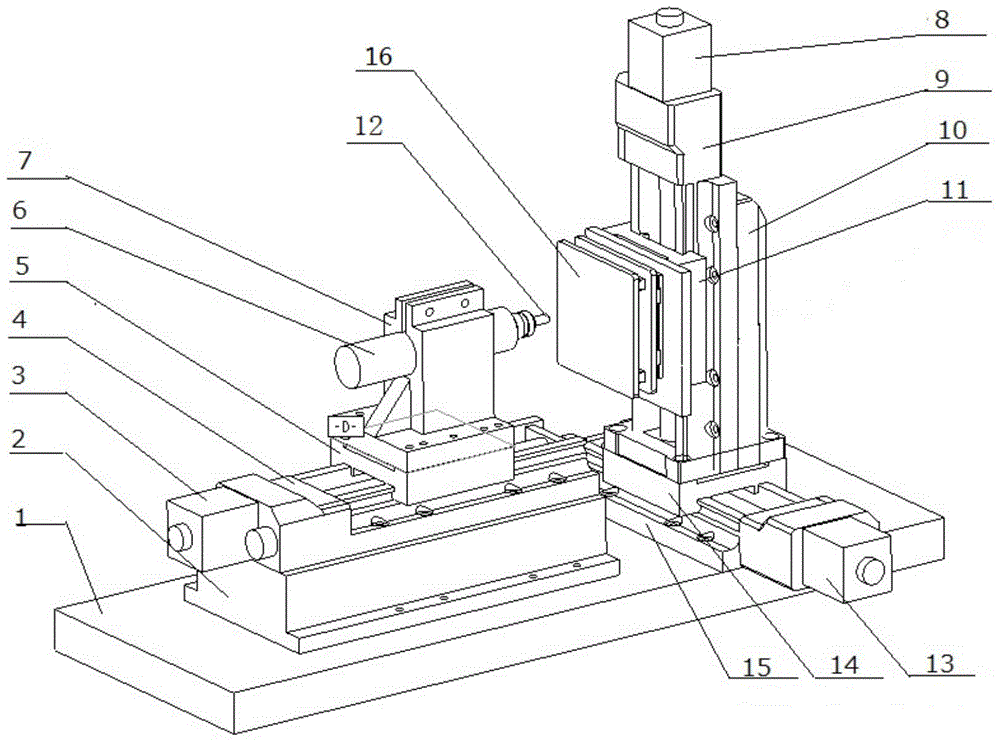

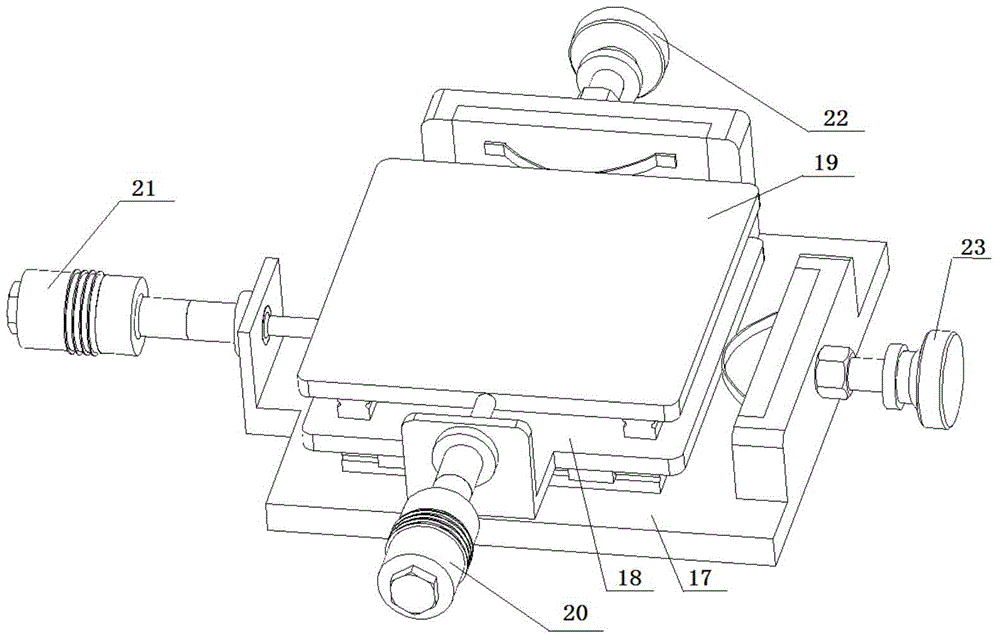

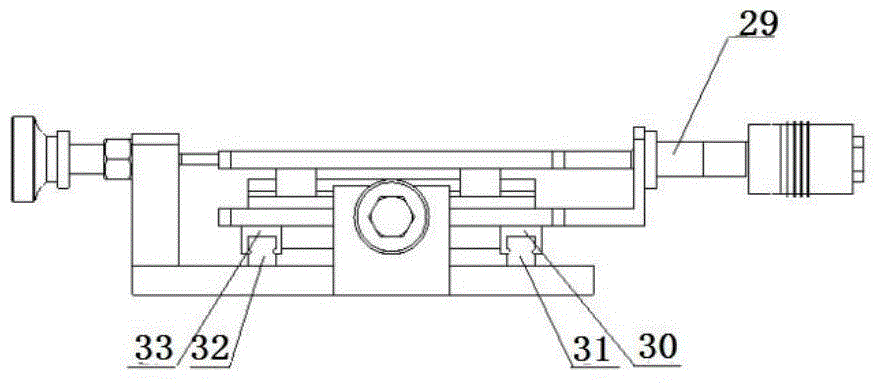

[0020] see Figure 1 to Figure 7 , a micro-milling system assisted by ultrasonic vibration, including a base 1 placed horizontally and an X-direction slide 4, a Y-direction slide 15 and a Z-direction slide 9 installed thereon; the X-direction slide 4, the The Y-direction slide table 15 and the Z-direction slide table 9 are all provided with a guide rail, a slide block and a motor installed on the guide rail, and a lead screw driven by the motor, and the lead screw is supported on the guide rail, The slide block is threadedly connected with the lead screw; a spacer 2 is provided under the guide rail of the X-direction slide table 4, and the spacer block is fixed on the base 1, and the X-direction slide table 4 is provided with There is an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com