Plane wing titanium alloy thin-wall web efficient numerical control machining technology

A processing technology, a titanium alloy technology, is applied in the field of high-efficiency CNC processing technology for aircraft wing titanium alloy thin-walled webs, which can solve the problems that cutting heat cannot be taken away by chips, high temperature at the tip of the tool, and wear on the blade surface. Achieve the effects of improving rigidity, improving surface roughness, and reducing cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

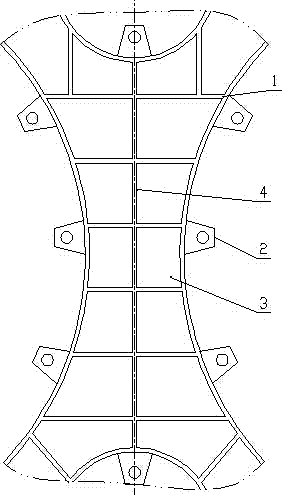

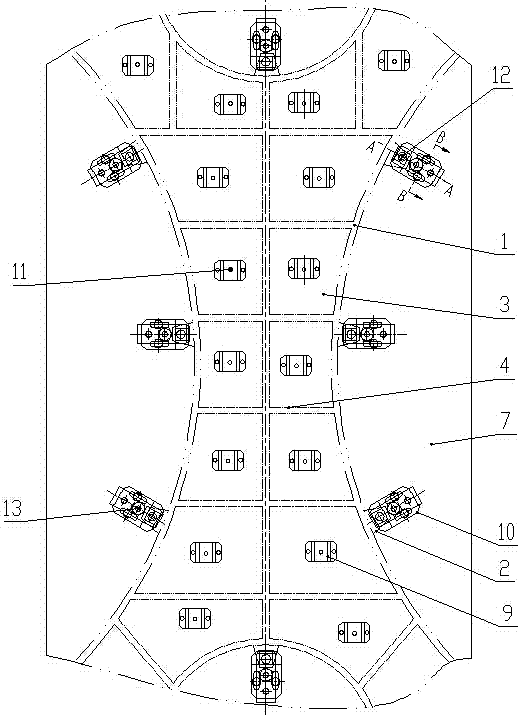

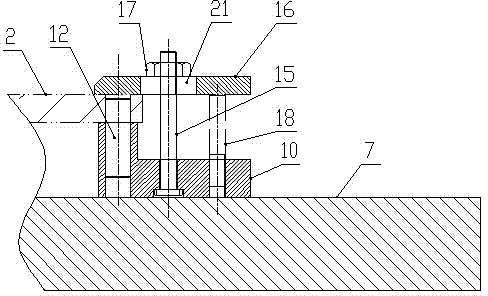

[0048] Such as Figure 1 to Figure 9 As shown, the high-efficiency numerical control machining process of the titanium alloy thin-walled web of the aircraft wing of the present invention comprises the following steps,

[0049] (1), blanking;

[0050] (2) Process the outer contour of the web 1 and process the lug 2 for positioning;

[0051] (3) Clamp the web 1 and process the cavity 3 on the front of the web 1;

[0052] (4), processing web side wall 4:

[0053] (5) The web 1 is quickly switched, and the cavity 3 and the web side wall 4 on the back of the web 1 are processed;

[0054] (6), milling off the positioning lug 2;

[0055] (7) Quality inspection.

[0056] The step (1) is specifically, using a plate with a material grade of Ti-6Al-4V, using a cutting machine to cut the plate into a rectangle, annealing, and the mechanical properties at room temperature σ b =895MPa, the blanking size is based on the design size of the web 1, and a machining allowance of 2mm is adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com