Helical milling device and method

A technology of helical hole milling and helical feeding, which is applied in the field of cutting processing, can solve the problems of difficult to guarantee machining accuracy, complex structure and composition, and large impact on weight, so as to reduce manufacturing costs, avoid frequent tool changes, and reduce tool wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The helical hole milling device and method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

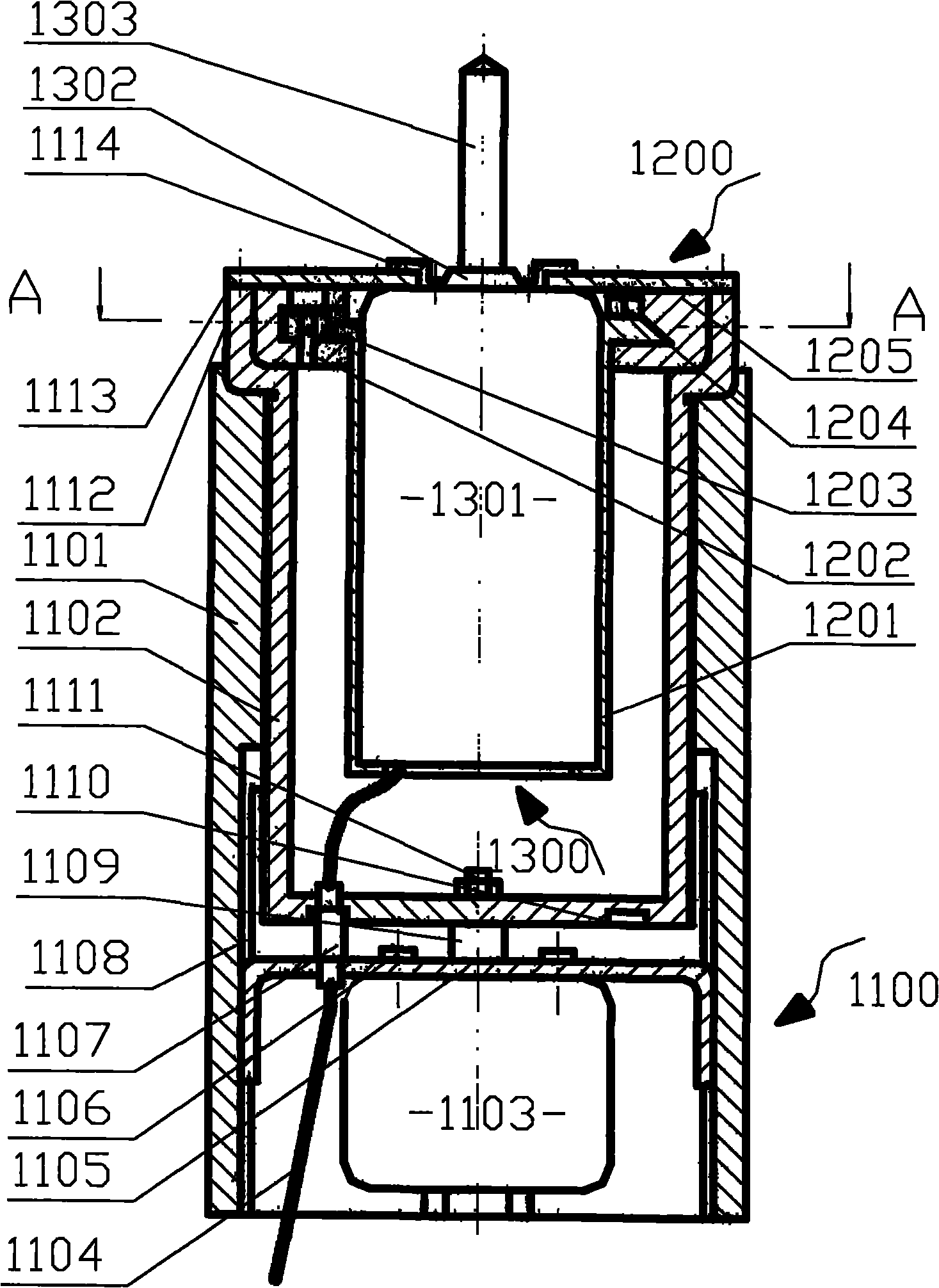

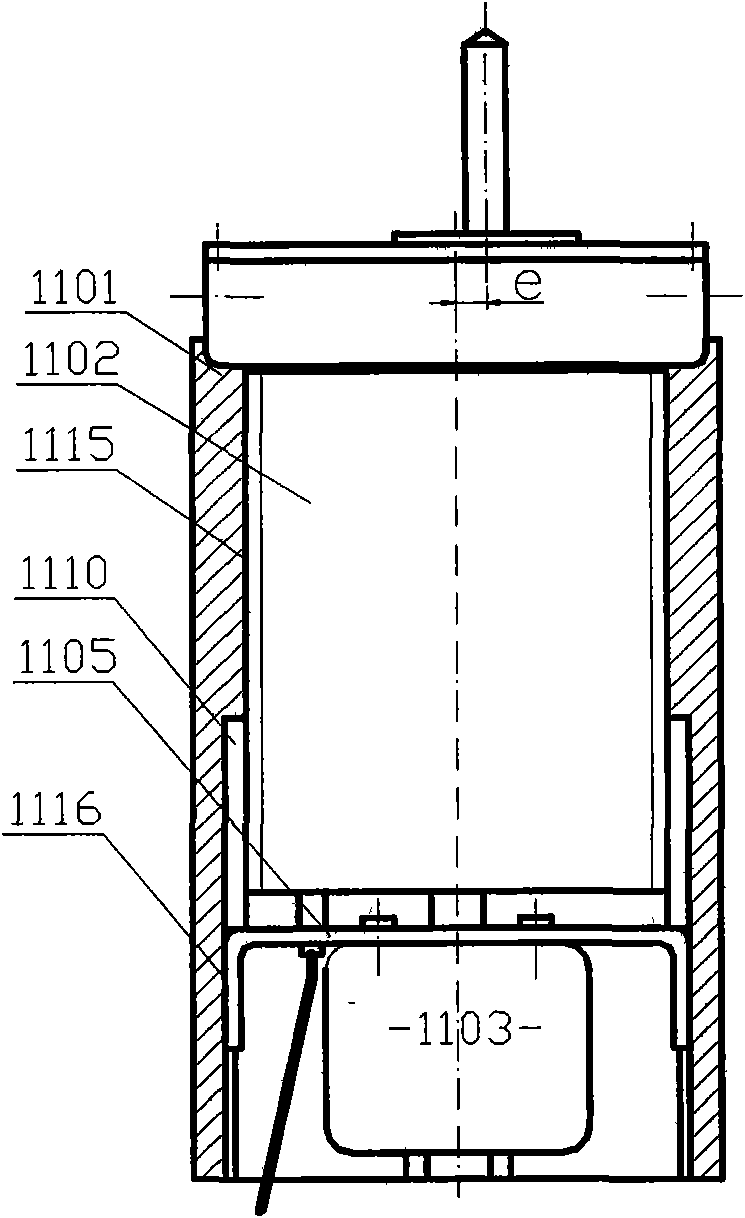

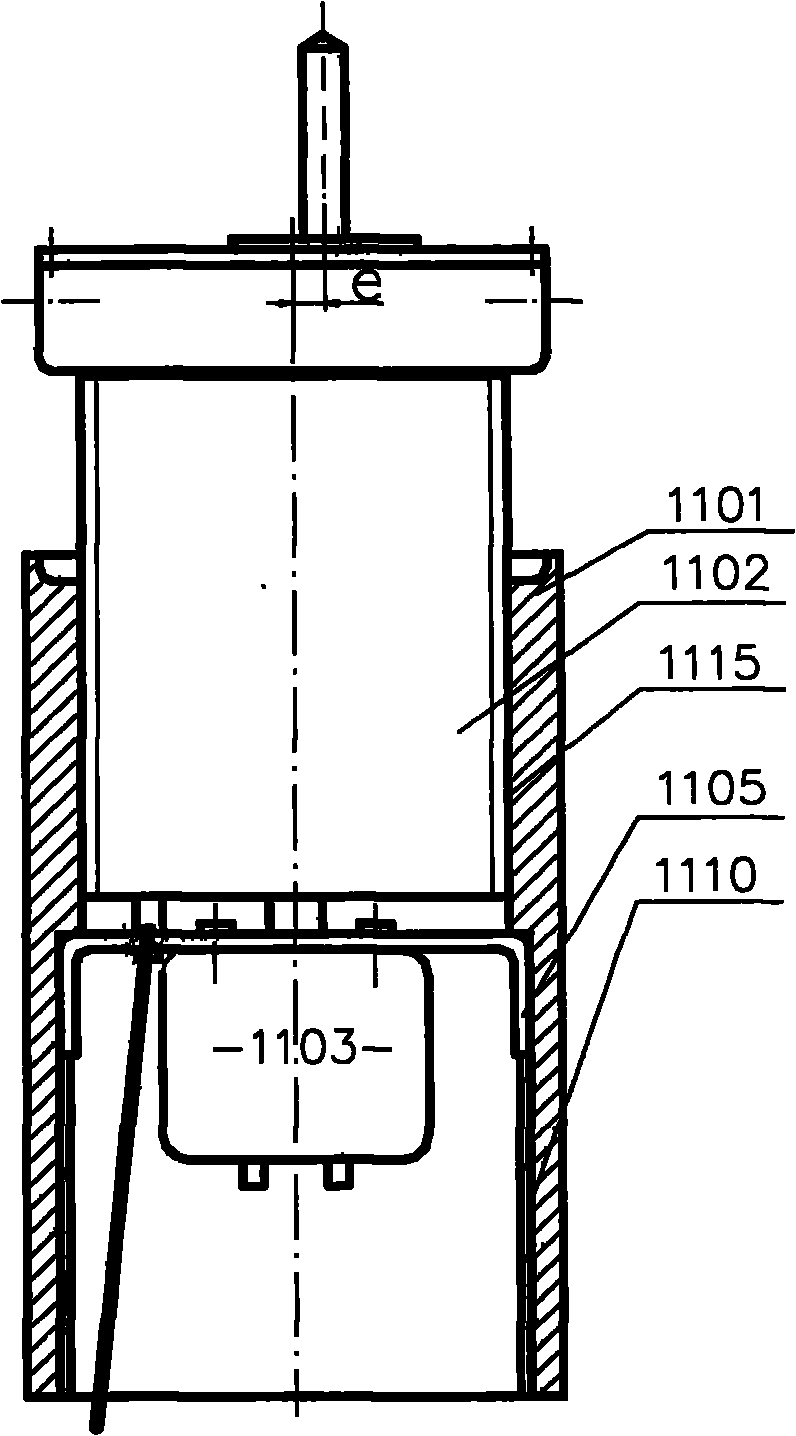

[0028] figure 1 It is a helical hole milling device disclosed in the present invention, which mainly includes a helical feeding mechanism 1100 , a radial offset mechanism 1200 , and a tool rotation mechanism 1300 . The radial offset mechanism 1200 is connected to the screw feed mechanism 1100 through the circumferential uniform bolts 1112 by adjusting the support end cover 1205 , and is fixedly connected to the tool rotation mechanism 1300 through the radial offset slider 1201 .

[0029] The cutter autorotation mechanism 1300, its autorotation motor 1301 is connected with the cutter 1303 of certain diameter through the cutter clamping mechanism 1302 at the end.

[0030] The screw feed mechanism includes a cylindrical housing 1101, a sliding bracket 1105 installed in the housing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com