Ultrasound ellipse vibration milling knife handle device

An elliptical vibration and milling cutter technology is applied in the fields of milling processing devices and milling tool shank devices, which can solve the problems of limiting the application of ultrasonic vibration milling technology, and achieve the effects of improving machining accuracy and surface quality, prolonging life, and convenient tool changing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

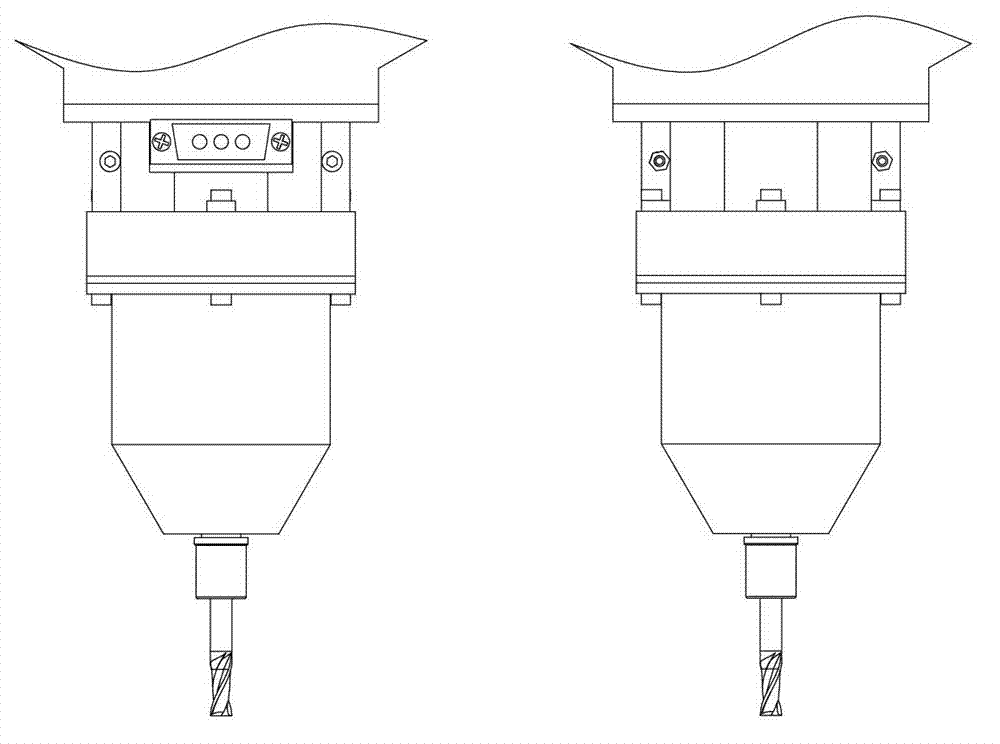

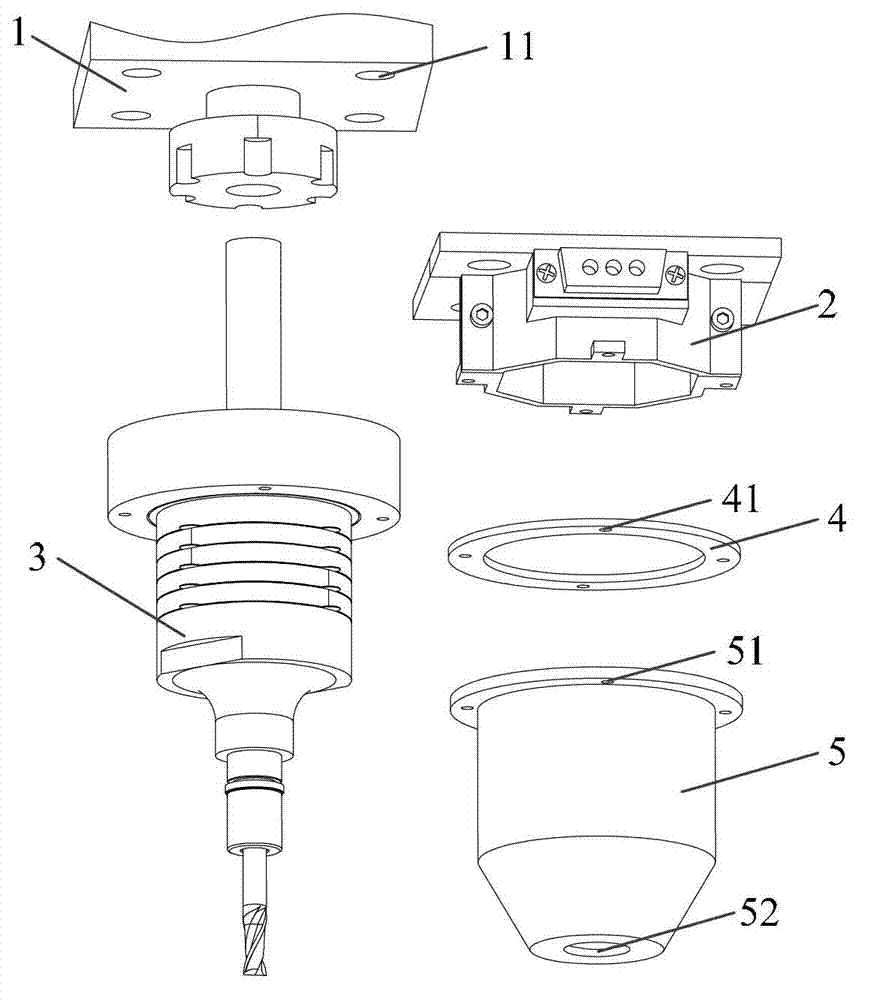

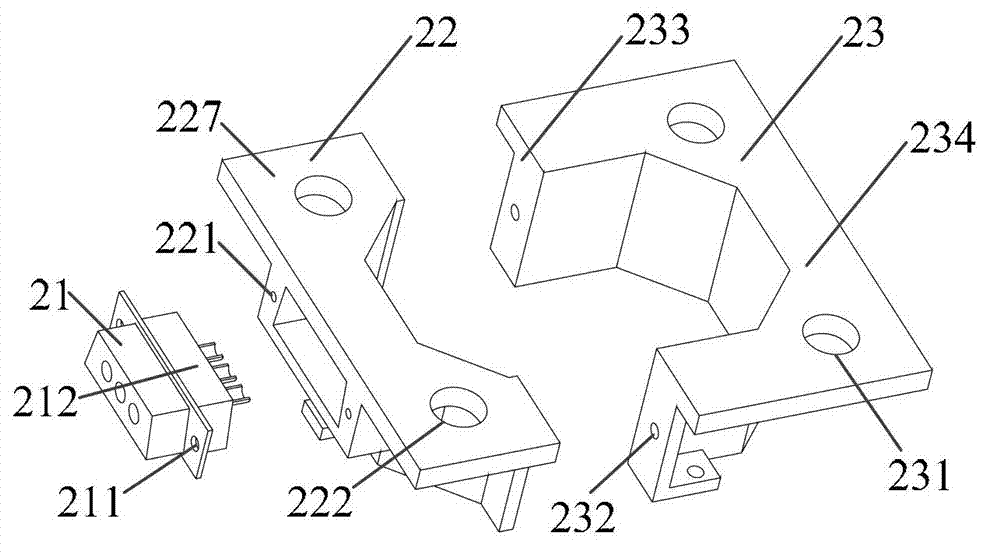

[0026] see figure 1 , figure 2 As shown, the cutterhead 1 is a CNC machine tool cutterhead. An ultrasonic elliptical vibration milling tool holder device of the present invention includes a power supply box 2 , an ultrasonic elliptical vibration milling tool holder 3 , a sealing ring 4 and a protective cover 5 . The position connection relationship between them is: the upper end surface of the power supply box 2 is connected with the lower plane of the cutter head 1 of the machine tool through bolts, the small round axis of the ultrasonic elliptical vibration milling tool holder is connected with the cutter head through a spring chuck, and the large cylindrical The upper end surface is screwed to the lower end surface of the power supply box 2, and the sealing ring 4 is placed on the lower end surface of the large cylinder, and is connected with the protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com