Mechanical hammering flattening device

A leveling and mechanical technology, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as high-efficiency surface quality and hardness metal mechanical hammer leveling technology, achieve good wear resistance, improve surface Integrity, low tool wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

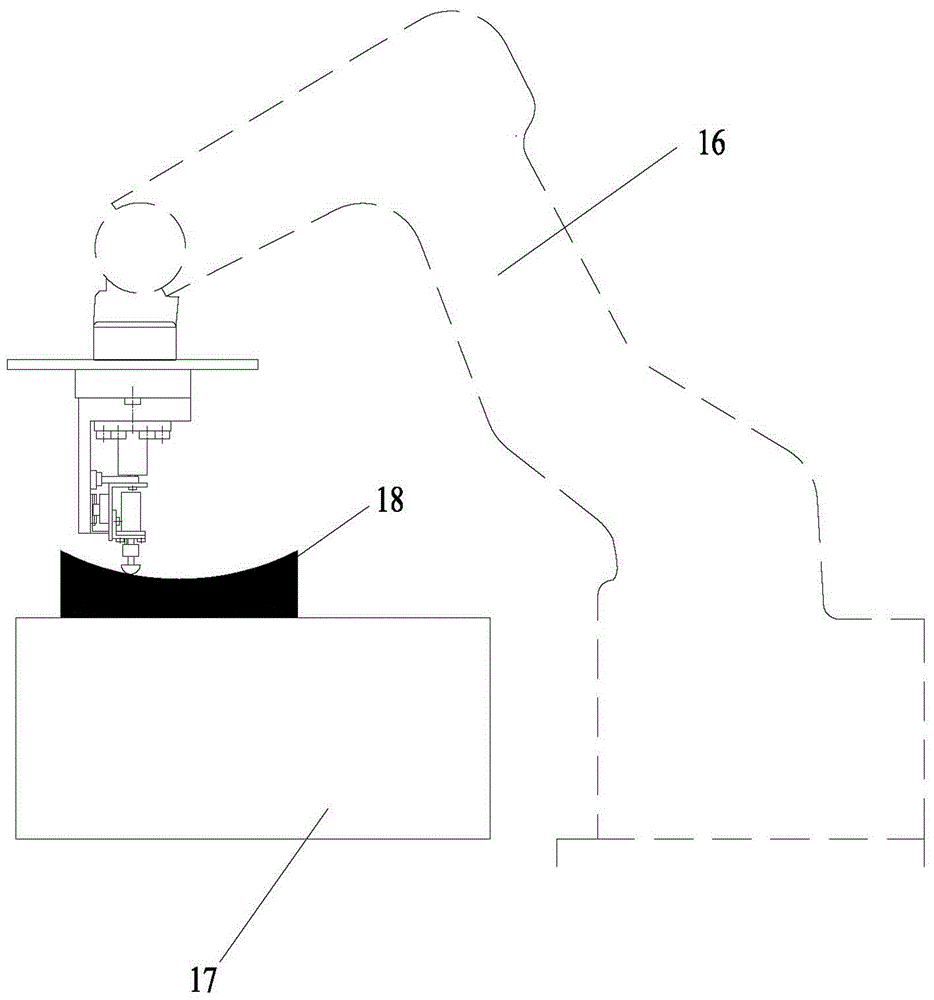

[0022] The present invention will be described in further detail below with reference to the drawings and specific embodiments.

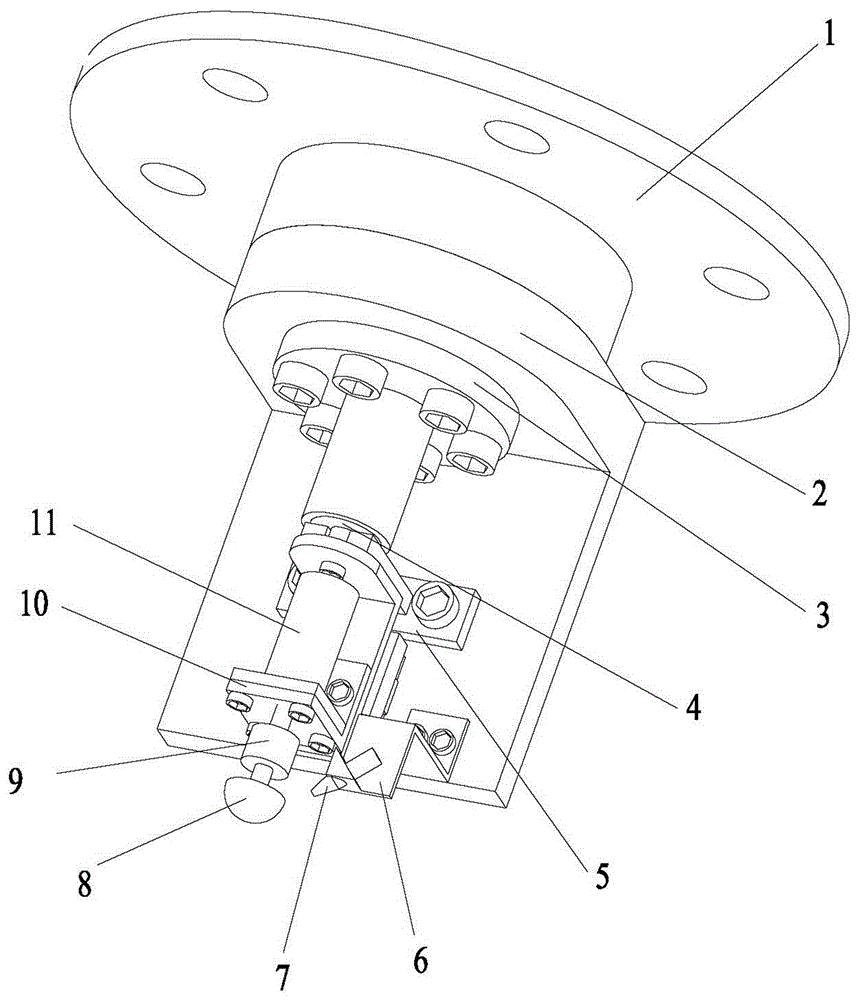

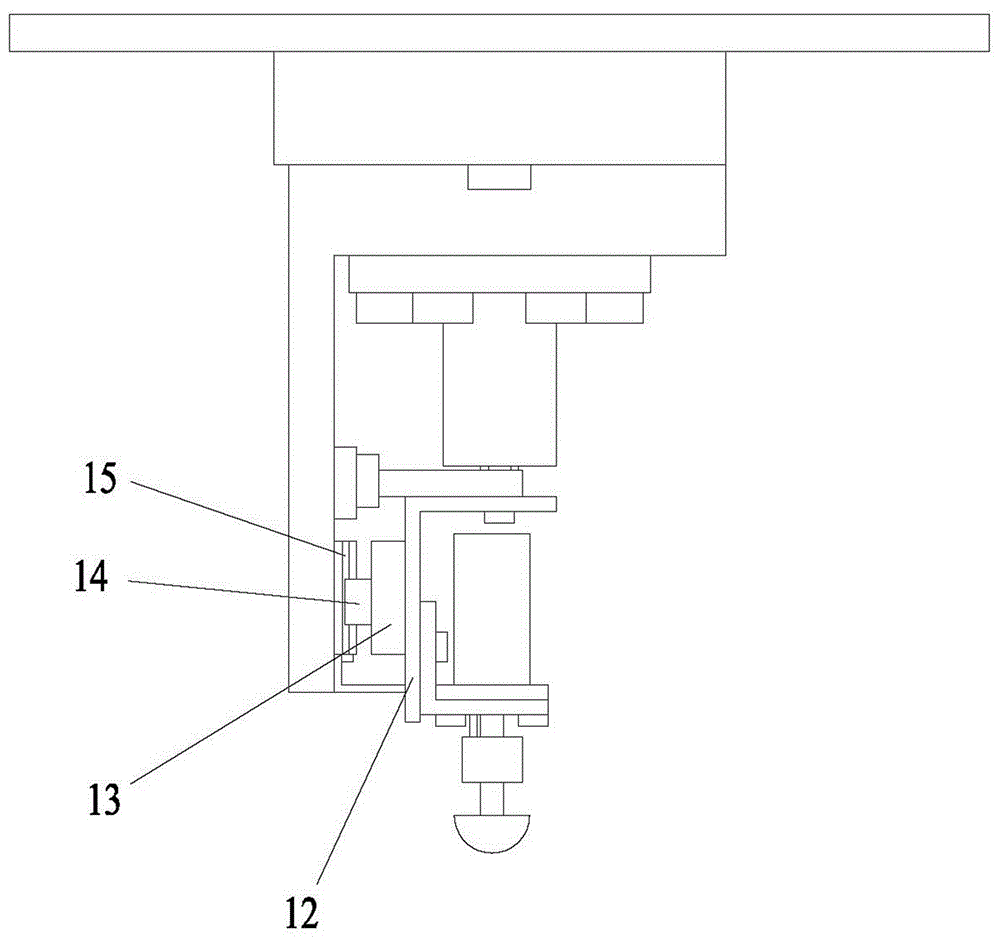

[0023] A mechanical hammering leveling device, including connecting flange 1, L-shaped plate 2, fixed flange 3, piezoelectric ceramic actuator 4, anti-lateral plate 5, Z-shaped plate 6, air gun 7, hammering head 8 , Adapter 9, motor fixing plate 10, motor 11, support frame 12, support plate 13, slider 14 and slide rail 15.

[0024] Such as figure 1 with 2 As shown, the connecting flange 1 is connected to the external flange by screws. The fixed flange 3 is fixed to the L-shaped plate 2 and the connecting flange 1 by screws, so the fixed flange 3, the L-shaped plate 2 and the connecting flange 1 are connected together. The fixed flange 3 is sleeved on the piezoelectric ceramic actuator 4 and closely matched. The piezoelectric ceramic actuator 4 is mounted on the L-shaped plate 2 by screws. The anti-lateral plate 5 is installed on the L-shaped plate 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com