Self-propelled type melon-striking and seed-extracting harvester

A self-propelled, harvester technology, used in harvesters, agricultural machinery and implements, threshing equipment, etc., can solve the problems of cumbersome harvesting of melons, low work efficiency, high labor intensity, etc., to achieve good promotion and use value, improve The effect of working efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Below in conjunction with accompanying drawing, self-propelled melon picking seed harvester of the present invention is described in detail below.

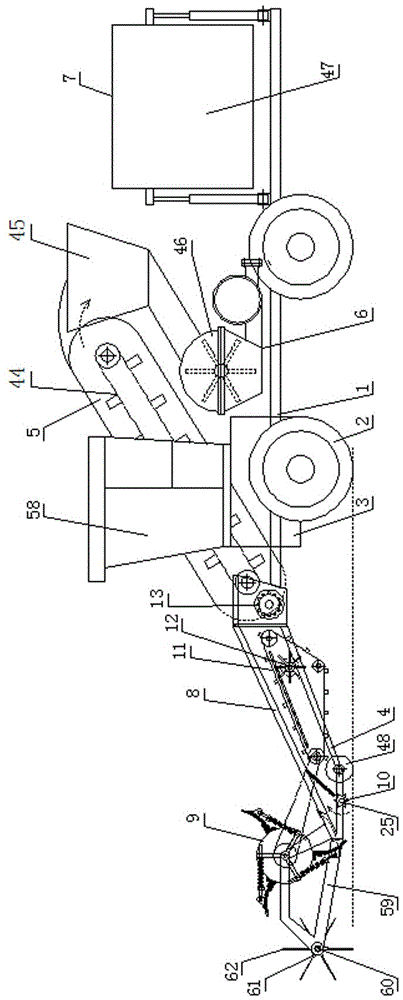

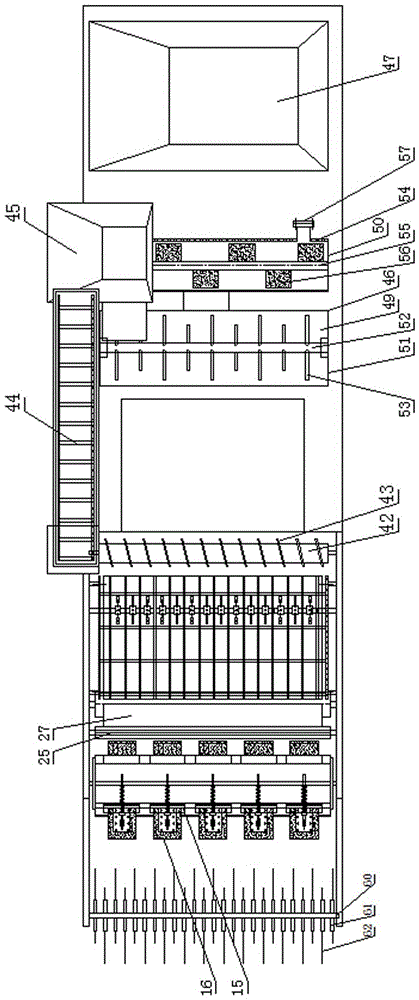

[0084] As shown in the accompanying drawings, the self-propelled melon seed harvester of the present invention includes a locomotive frame 1, wheels 2, power mechanism 3, tillage platform 4, lifting mechanism 5, melon seed removal mechanism 6 and storage Agency 7;

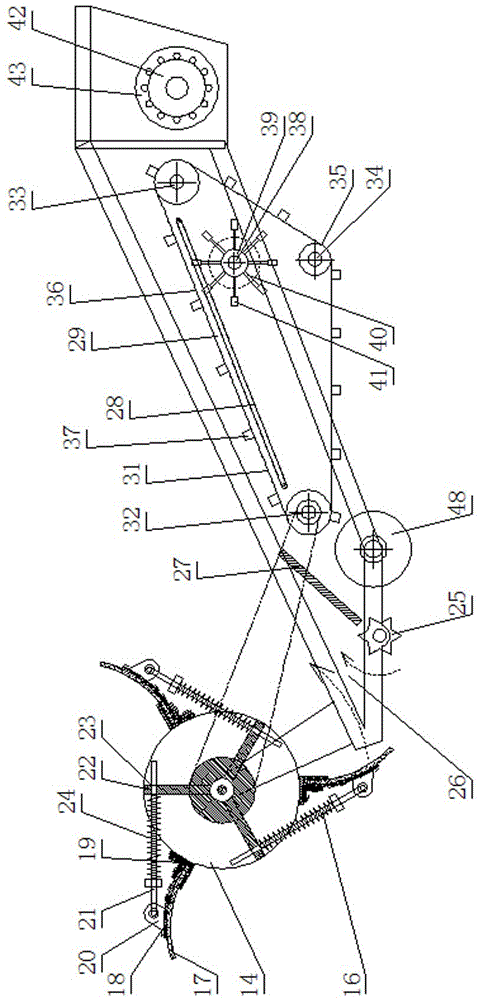

[0085] The cultivating platform 4 includes a cultivating platform frame 8, a melon picking mechanism 9, an auxiliary melon picking mechanism 10, a melon body conveying mechanism 11, a seedling beating mechanism 12, and a horizontal screw conveying mechanism 13;

[0086] The cultivating platform frame 8 and the locomotive frame 1 are connected in one or more combinations of fixed connection, lifting connection, and swing hinge at elevation and depression angles.

[0087] The structure of the melon grabbing mechanism 9 is: the roll away roller 14 is erected horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com