Panel machining equipment for low-smoke furnace and machining technology of panel machining equipment

A panel processing and smoke furnace technology, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of cutting panel surface damage, easy deviation, increased raw materials and processing costs, etc., to ensure the surface, reduce The effect of stacking extrusions on top of each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

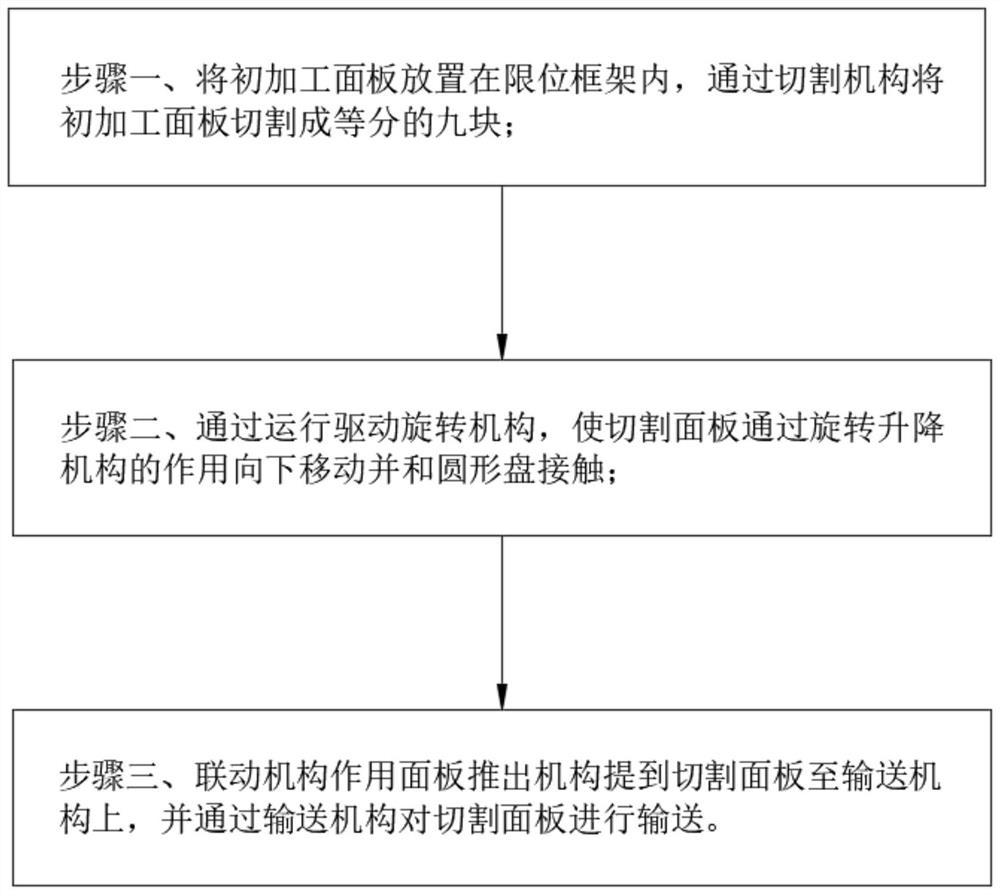

Method used

Image

Examples

Embodiment approach

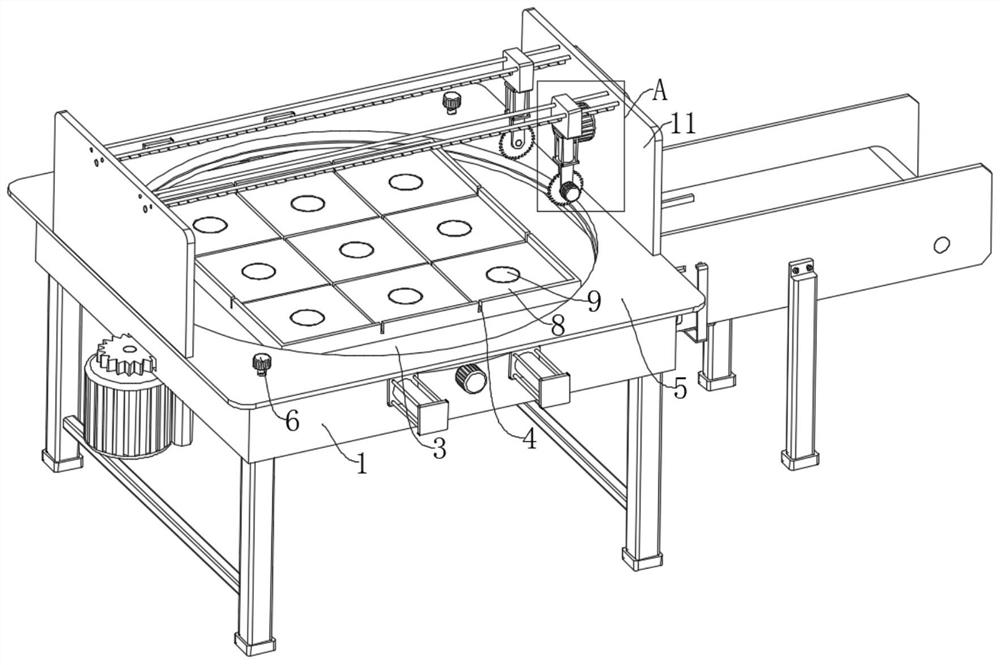

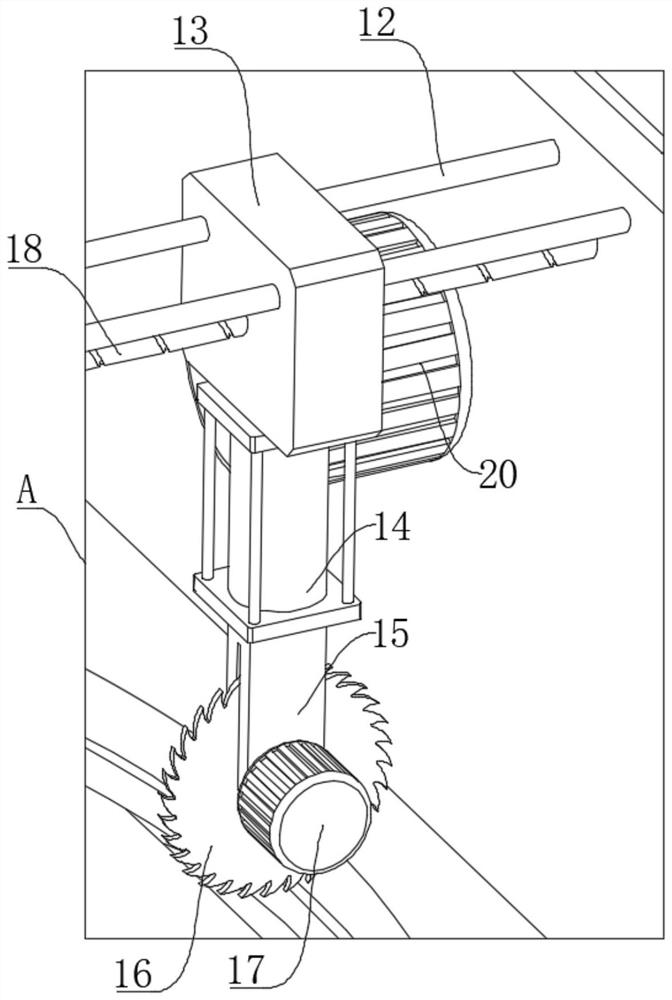

[0049] As an embodiment of the present invention, the cutting mechanism includes two rectangular plates 11, and the two rectangular plates 11 are respectively fixedly connected to both sides of the top of the rotating frame 5, and both sides of the rectangular plates 11 are fixedly connected with two circles. Shaped rods 12, a rectangular block 13 is slidingly connected between two adjacent circular rods 12, a hydraulic cylinder 14 is fixedly installed on the bottom of the rectangular block 13, and a connecting block is fixedly connected to the output shaft at the bottom of the hydraulic cylinder 14 15, the bottom of connecting block 15 is all rotatably connected with cutting blade 16, and one side of connecting block 15 is all fixedly installed with driving motor 17, and the output shaft of driving motor 17 is fixedly connected on one side of adjacent cutting blade 16, and rectangular block 13 The first screw rod 18 is threaded on the top, and the two ends of the first screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com