Metal tube antirust paint internal and external synchronous spraying equipment

The technology of spraying equipment and anti-rust paint is applied in the field of synchronous spraying equipment inside and outside the anti-rust paint for metal cylinders, which can solve the problems of low efficiency of manual painting and difficult painting of the inner and outer walls of metal cylinders, and achieves fast clamping speed and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

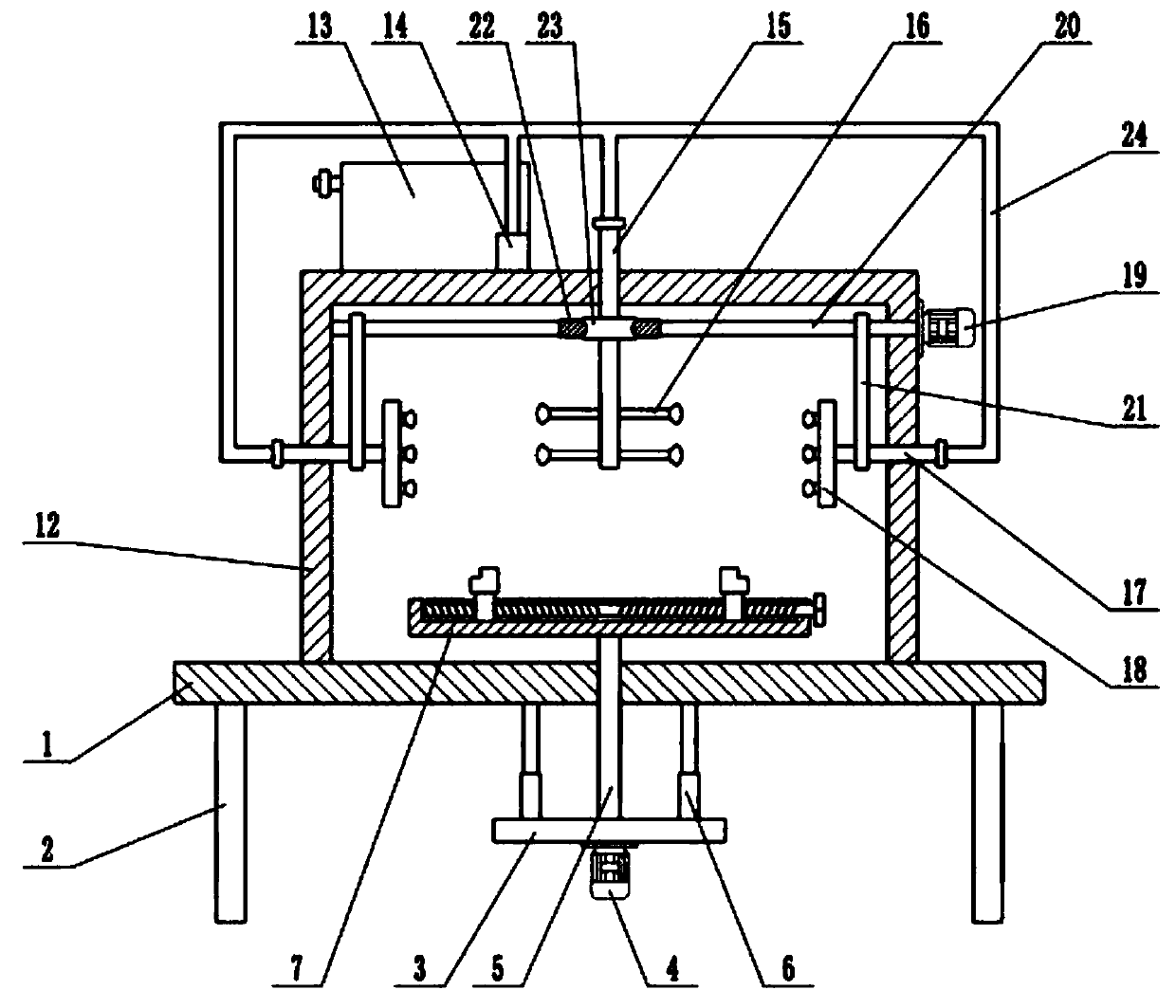

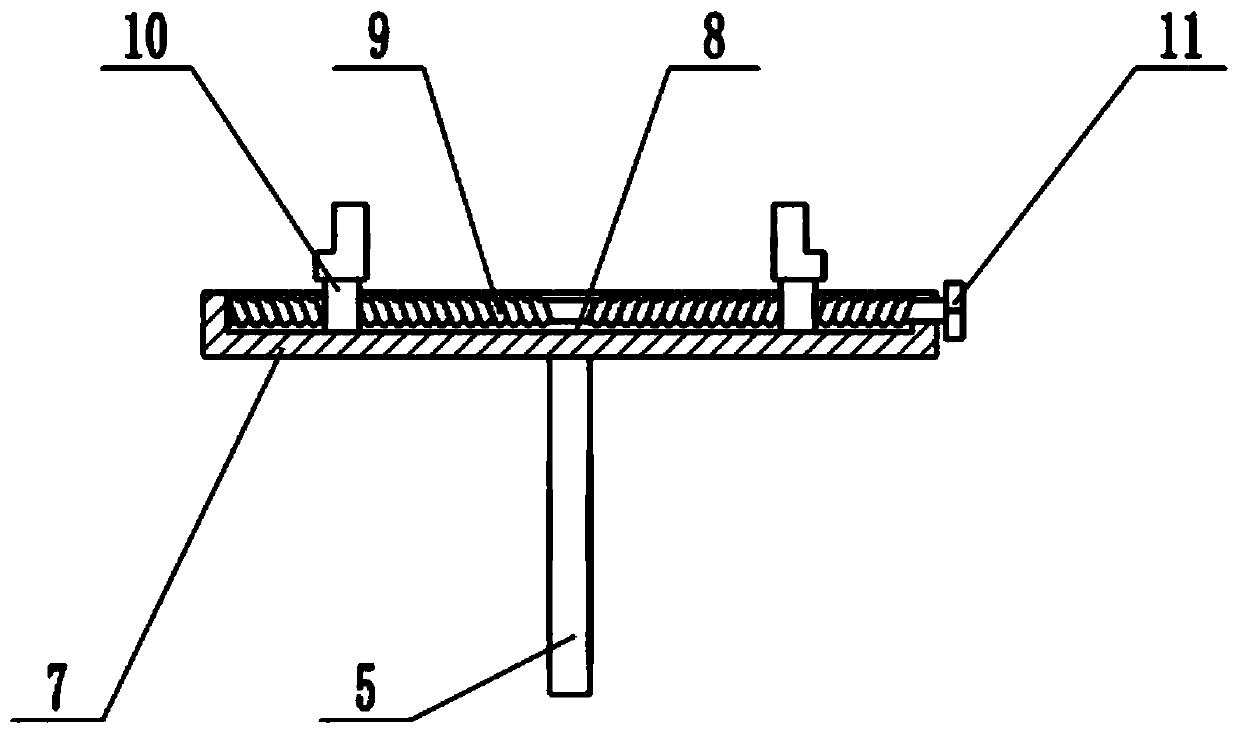

[0023] see Figure 1-4 , In the embodiment of the present invention, a metal cylinder anti-rust paint inside and outside synchronous spraying equipment, including a workbench 1, a turntable 7, a fixed frame 12, a liquid storage tank 13 and a spray disc 18, the bottom of the workbench 1 is fixedly connected with feet 2 , There is a lifting plate 3 below the workbench 1, the upper surface of the lifting plate 3 is fixedly connected with a telescopic mechanism 6, the telescopic mechanism 6 is an electro-hydraulic telescopic rod, and the top of the telescopic mechanism 6 is fixedly connected to the lower surface of the workbench 1. The lower surface of the plate 3 is fixedly connected with the first motor 4, the shaft extension end of the first motor 4 is fixedly connected with the rotating shaft 5, the top of the rotating shaft 5 extends through the workbench 1 to the top of the workbench 1, and the rotating shaft 5 is connected to the workbench 1. The top of the rotating shaft 5...

Embodiment 2

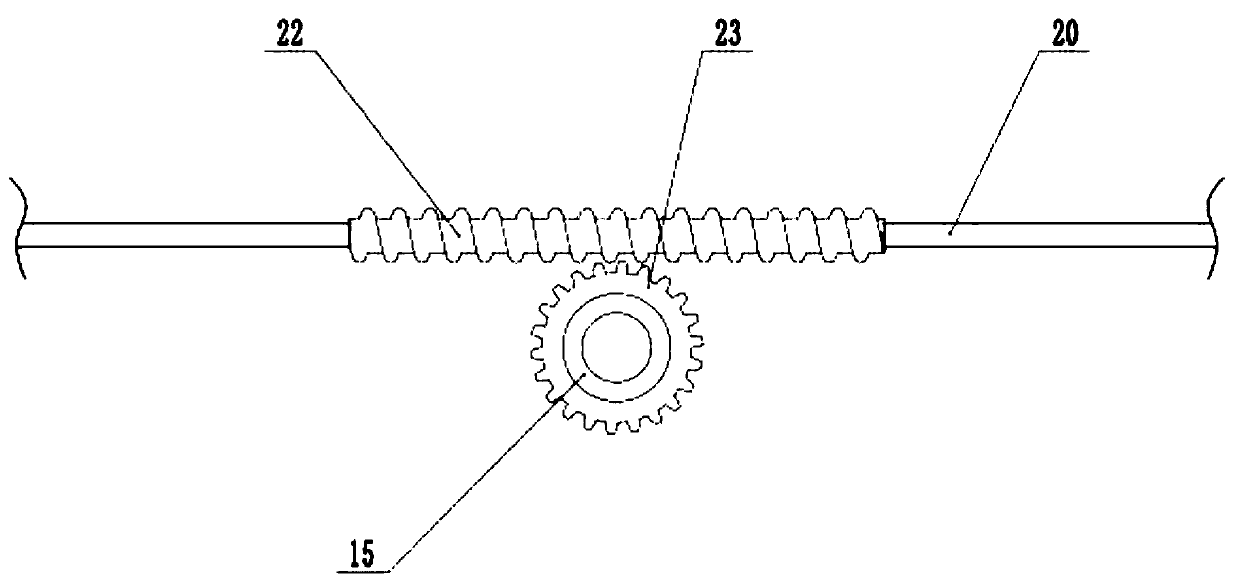

[0025] On the basis of Embodiment 1, the second hollow shaft 17 is connected to the drive shaft 20 through the transmission belt 21. When the drive shaft 20 rotates, it drives the second hollow shaft 17 to rotate synchronously, thereby driving the spray disc 18 to rotate, so that the anti-rust paint is more Spray evenly on the outer wall of the metal cylinder.

[0026] Combined with Embodiment 1 and Embodiment 2, the working principle of the present invention is as follows: the metal cylinder to be painted is placed on the turntable 7, the knob 11 is rotated, and the two-way screw 9 is driven to rotate, thereby driving the two clamping blocks 10 to move toward each other, The upper surface of the clamping block 10 is fixedly connected with an arc-shaped clamping plate. The arc-shaped clamping plate is used to clamp the side wall of the metal cylinder to keep the metal cylinder stable. Drive the turntable 7 to move upward, make the nozzle 16 enter the inside of the metal cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com