Working table for stone machining

A stone processing and workbench technology, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of inconvenient rotation, difficulty in adjusting the inclination angle of stone, inconvenience, etc., to save workers' time, facilitate processing operations, and improve efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

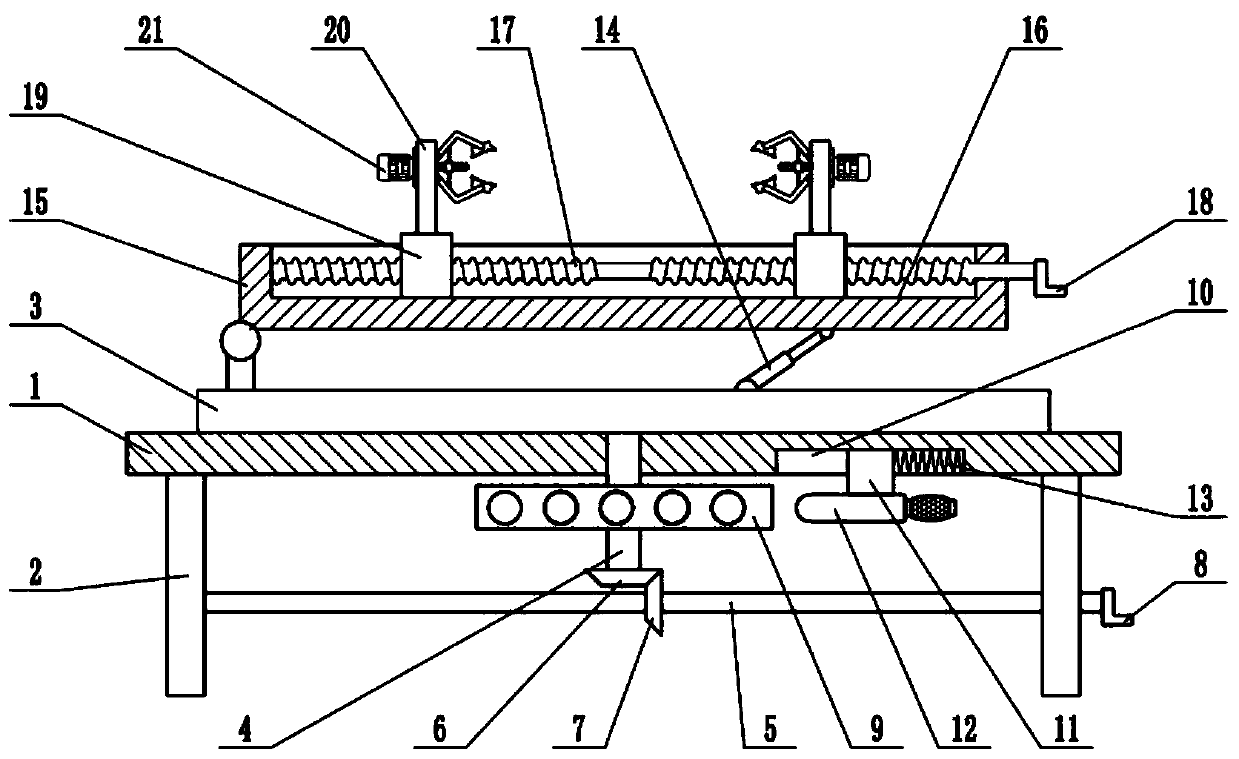

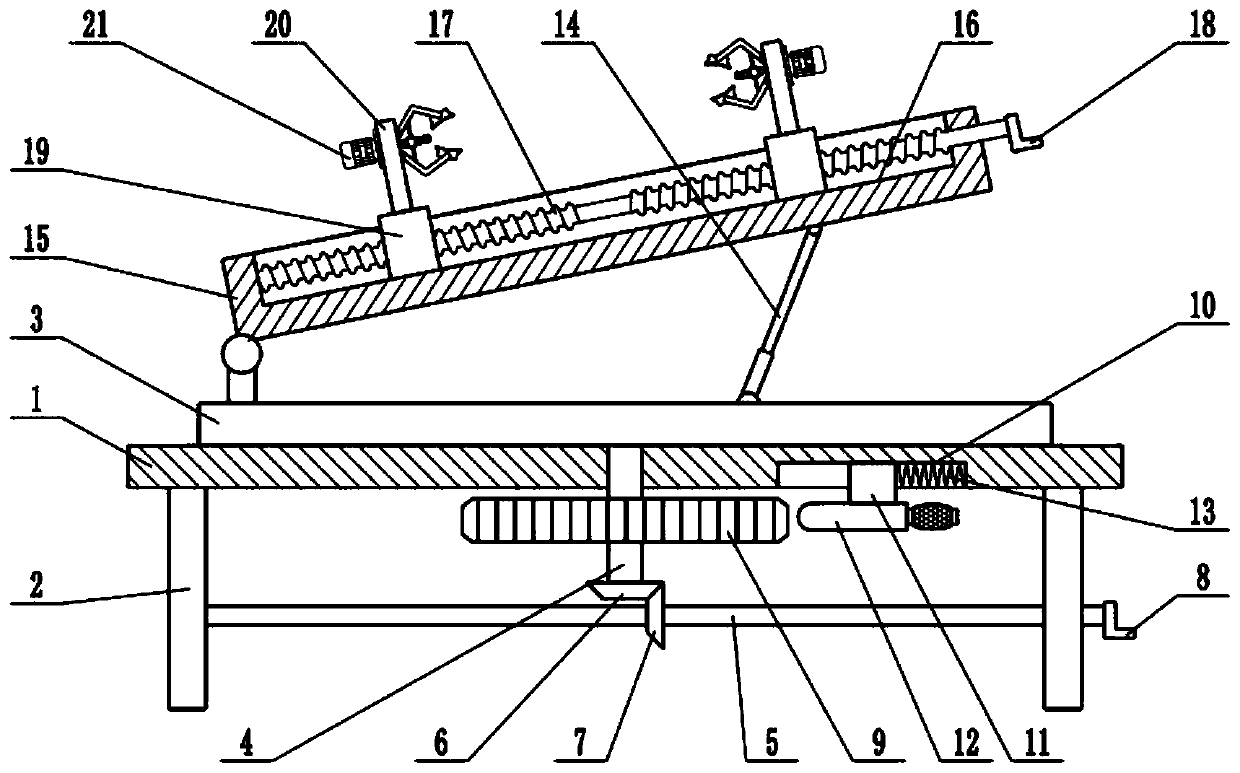

[0021] see Figure 1-4 , in an embodiment of the present invention, a workbench for stone processing includes a table top 1, a movable plate 15, a clamping block 19 and a clamping plate 20, the lower surface of the table top 1 is fixedly connected with a support plate 2, and the bottom surface of the table top 1 The upper surface is rotatably connected with a rotary table 3, and the lower surface of the rotary table 3 is fixedly connected with a rotating shaft 4. The lower end of the rotating shaft 4 passes through the table top 1 and extends to the bottom of the table top 1. The rotating shaft 4 is connected to the table top 1 in rotation. The transmission shaft 5, the two ends of the transmission shaft 5 are respectively connected to the support plate 2 in rotation, the end of the transmission shaft 5 is equipped with a first handle 8, the middle part of the transmission shaft 5 is provided with a second bevel gear 7, and the lower end of the rotation shaft 4 The first bevel...

Embodiment 2

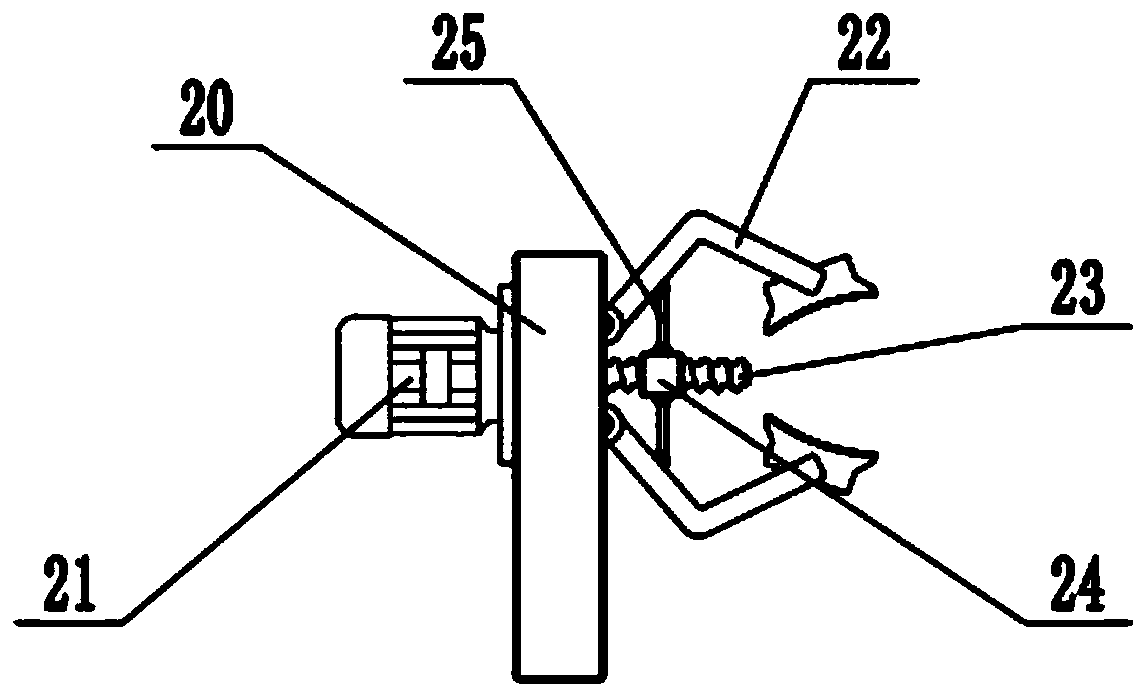

[0023] On the basis of Embodiment 1, a clamping plate 20 is fixedly connected to the upper surface of the clamping block 19, and a clamping mechanism is installed on the clamping plate 20. The clamping mechanism includes a clamping motor 21, clamping jaws 22, clamping wire Rod 23, slide block 24 and clamping link 25, one side of clamping plate 20 is fixedly connected with clamping motor 21, and the shaft extension end of clamping motor 21 is fixedly connected with clamping screw rod 23, and clamping plate 20 The other side is hinged with jaws 22. There are two jaws 22 arranged symmetrically up and down. A clamping link 25 is hinged, and the end of the clamping link 25 is hinged with the slide block 24. The clamping motor 21 is a positive and negative motor, and the positive and negative rotation of the control clamping motor 21 can drive the clamping screw mandrel 23 to rotate. Thereby, the slide block 24 is driven to move laterally, and the jaws 22 are driven to open or close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com