Robot electric gripper

A robot and gripper technology, applied in the field of robot electric grippers, can solve the problems that materials cannot be grasped, grasping speed, grasping force cannot be adjusted, and the gripper is not flexible enough to achieve clamping speed Fast, small impact load, stable transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

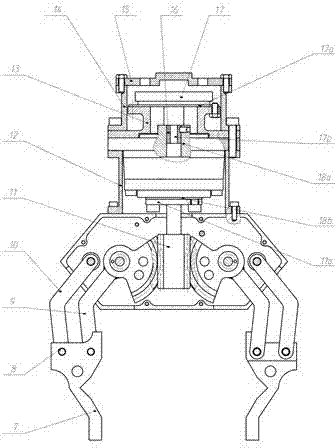

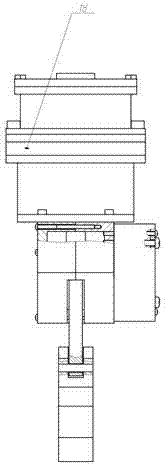

[0021] Such as figure 1 , 2 , 3, the robot electric gripper can be divided into three parts, namely: the drive-control part composed of the motor drive module inside the motor 17, the cover 1; the harmonic reducer 18, the worm 11, the worm gear The deceleration-power-increasing part formed by the curved rod 9 (ie, the crooked connecting rod); The harmonic reducer 18 is positioned through the first flange 12, the motor 17 is connected to the harmonic reducer 18 through the second flange 13, and the entire electric gripper is ensured to be compatible with the robot through the third flange 14. Finally, the gripper is fixed to the robot through the fourth flange 15. The casing made of case cover one 2 and case cover two 5 is used for fixing the parallel clamping structure.

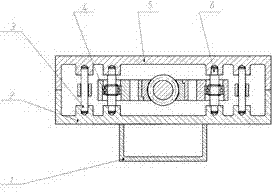

[0022] Such as Figure 4 As shown, the connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com