3D printer consumable item conveying clamping device based on magneto-rheological effect

A 3D printer and magneto-rheological effect technology, applied in the direction of manufacturing auxiliary devices, 3D object support structures, additive processing, etc., can solve problems such as improper clamping force, abnormal transmission of consumables, and slippage of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

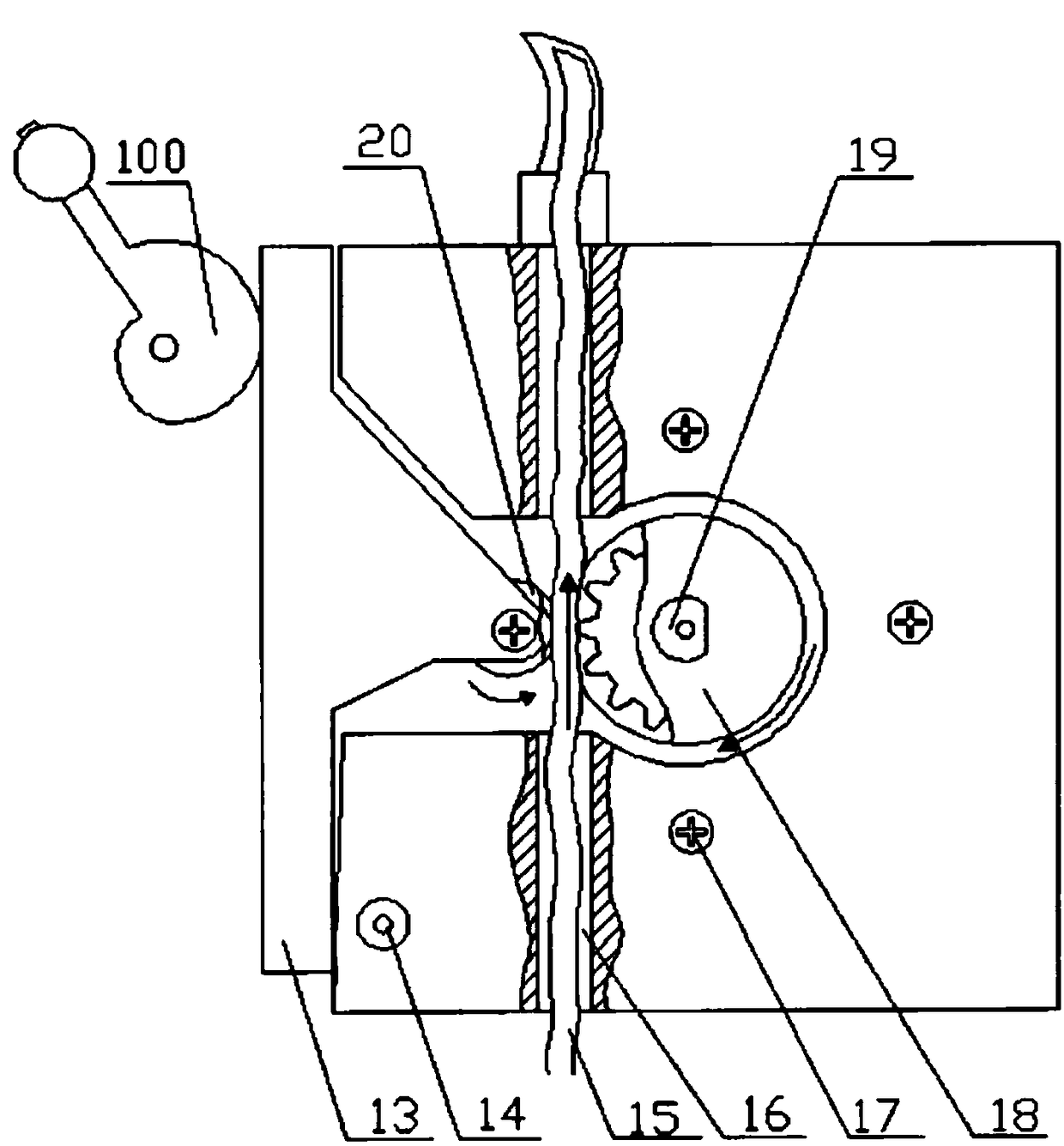

[0009] exist figure 1 Among them, the transmission part of a 3D printer consumable transmission and clamping device based on the magneto-rheological effect of the present invention is mainly composed of a rotating rod 13 , a driving gear 18 and a driven bearing 20 .

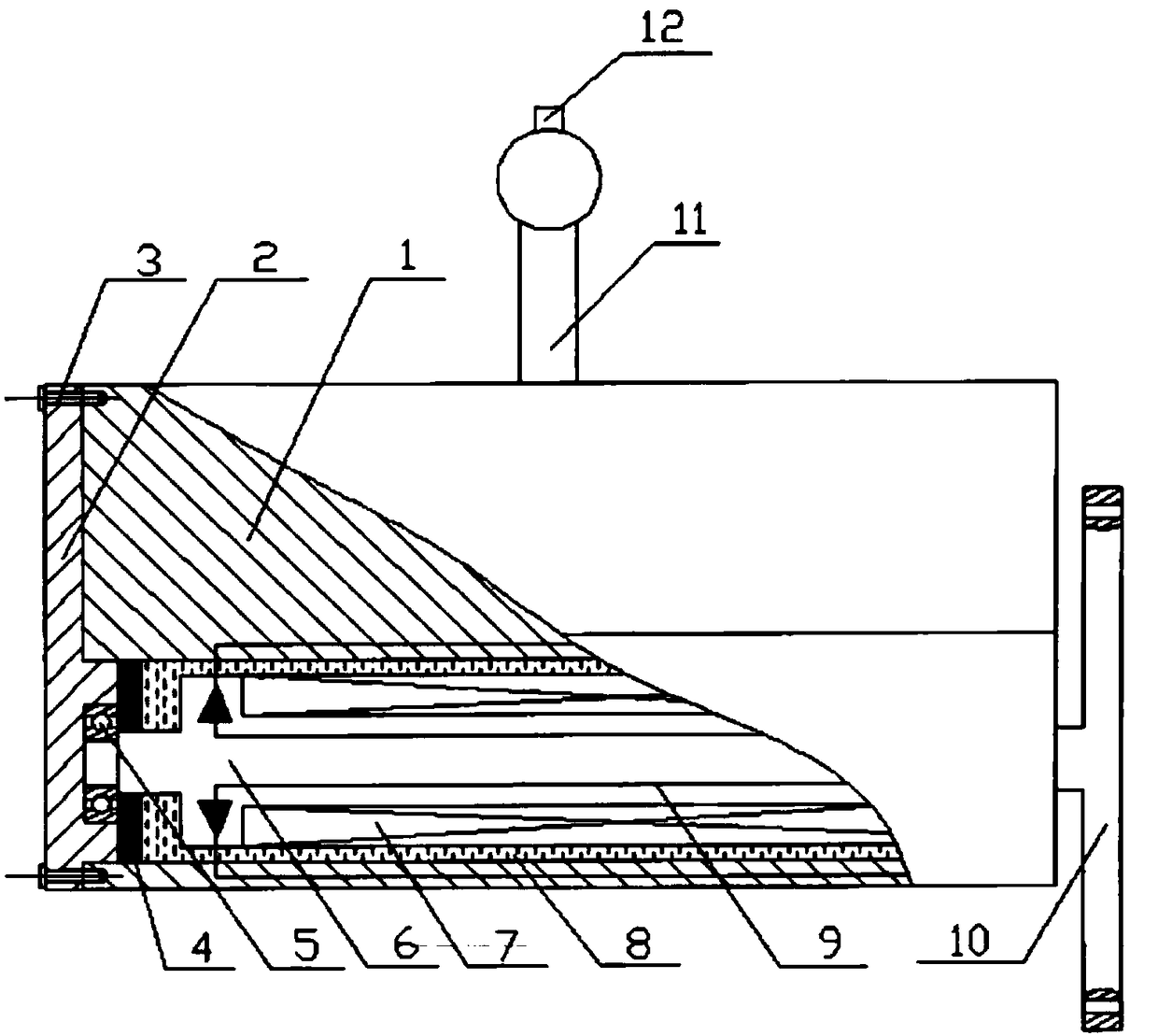

[0010] exist figure 2 Among them, the present invention is a 3D printer consumable transmission and clamping device based on the magneto-rheological effect. The core part of the clamping device includes a rotating cylinder 1, an end cover 2, a screw 3, a sealing sleeve 4, a bearing 5, and a fixed shaft 6 , induction coil 7, magnetorheological fluid 8, fixed end seat 10, handle 11, button 12.

[0011] In the clamping device of the core part: the rotating cylinder 1 is involute shape with increasing radius, and can rotate around the fixed shaft 6 through the bearings 5 at both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com