Ceramic ball surface quality detection device

A technology of surface quality and detection device, applied in the field of electromechanical, can solve the problems of detection blind spot, the surface of the unfolding wheel loses shape, the ceramic ball cannot be unfolded according to the design trajectory, etc., and achieves the effect of improving the detection speed and the clamping speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in conjunction with accompanying drawing:

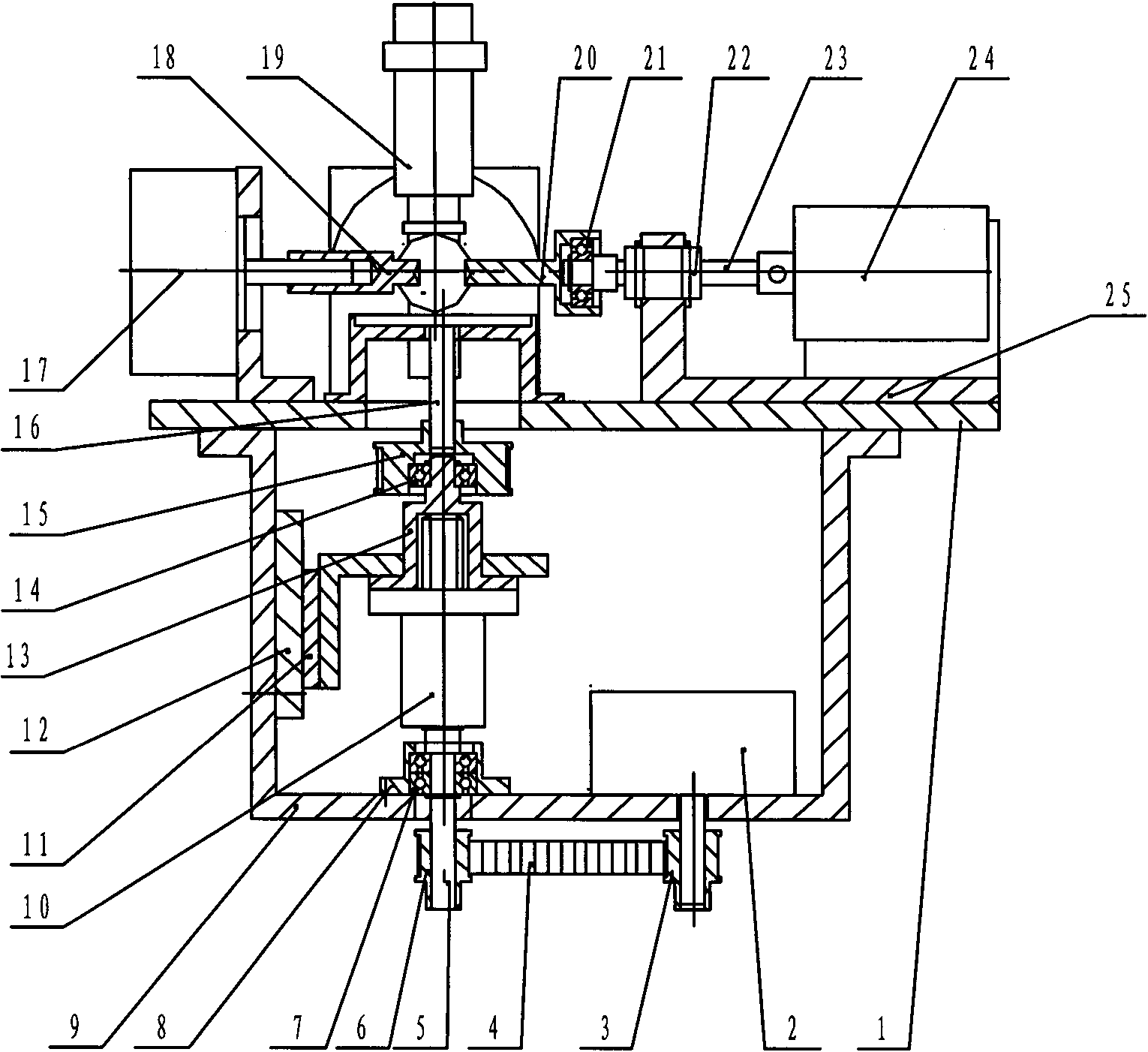

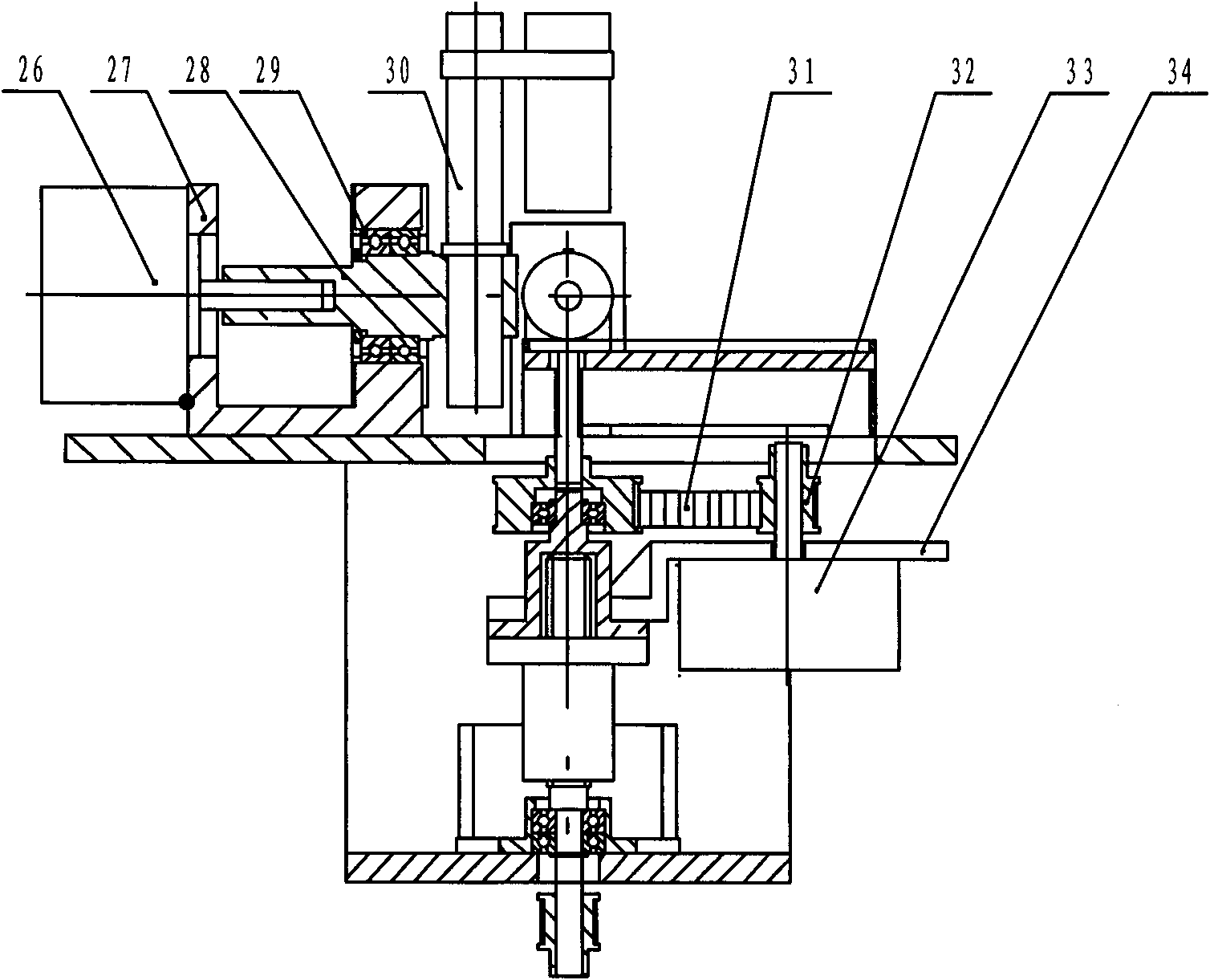

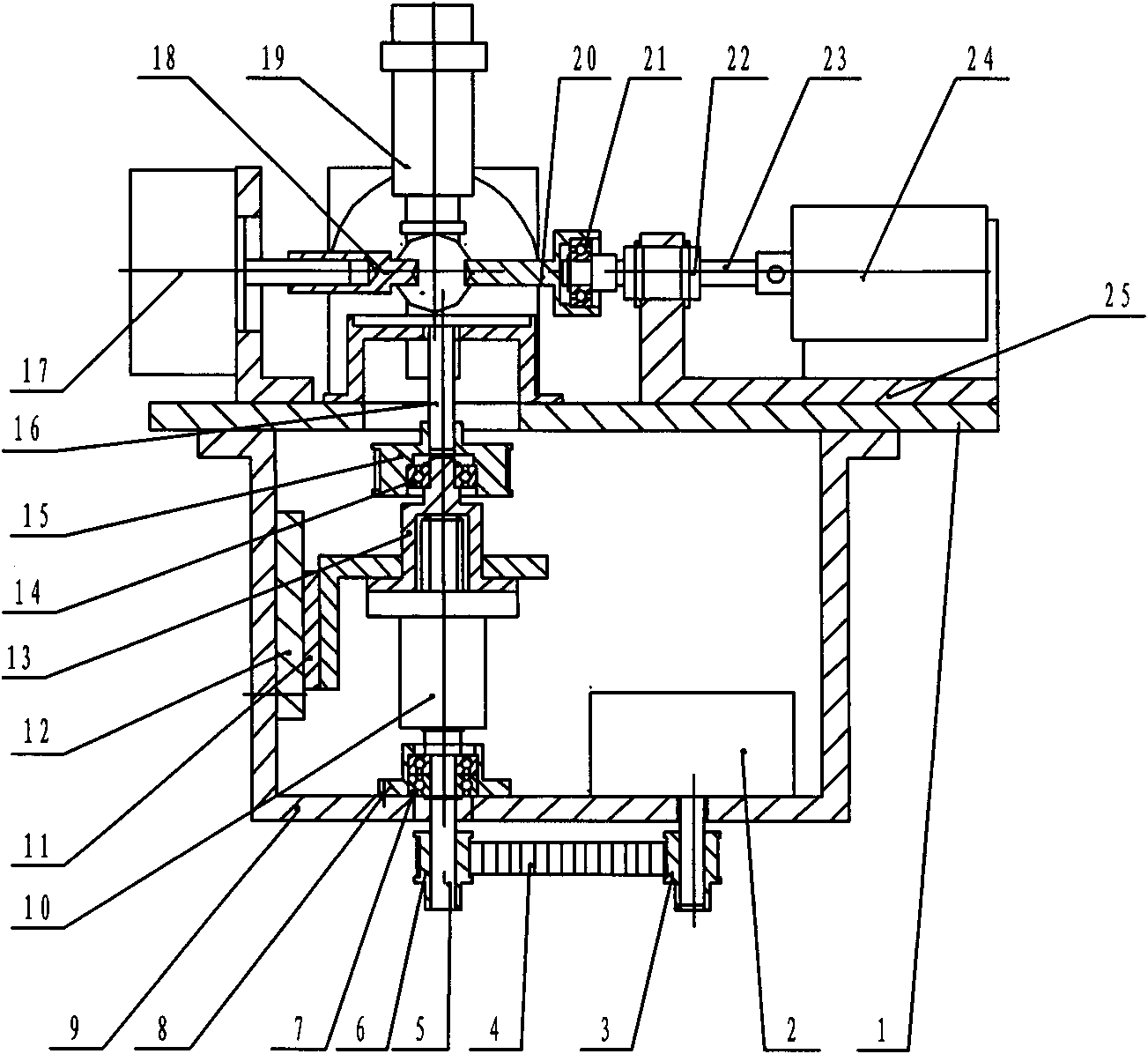

[0017] This device is a ceramic ball surface quality detection device. The device adopts the spiral spherical belt expansion method or the parallel spherical belt expansion method to replace the current spiral conjugate axis expansion method, and uses the fixture to drive the ball to rotate forcibly. The microscope-CCD system is rotated around the sphere to realize spherical expansion. This device is suitable for the detection of all balls with small surface defects and small volume.

[0018] The device comprises a frame 1, a clamping assembly, a ball lifting assembly, a ball vertical rotation assembly, a ball horizontal rotation assembly and a microscope swing assembly. The clamping assembly, the ball lifting assembly, the ball vertical rotation assembly, and the ball horizontal rotation assembly are installed on the frame 1 by screws respectively. The clamping assembly and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com