Automatic machining clamp with multi-directional adjustment function

A multi-directional adjustment and fixture technology, used in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of low production efficiency, trouble, time-consuming and laborious, and achieve fast clamping speed, convenient use, and easy processing. The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

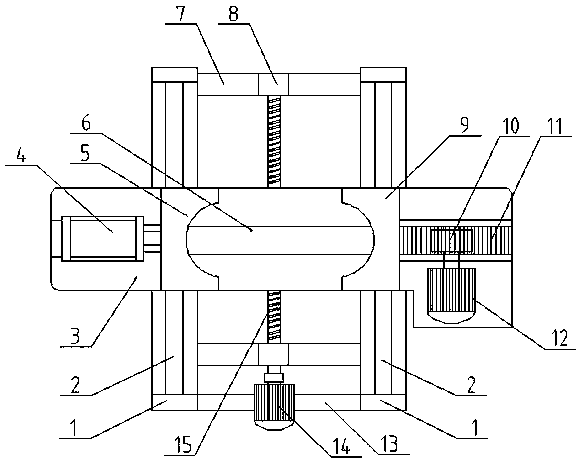

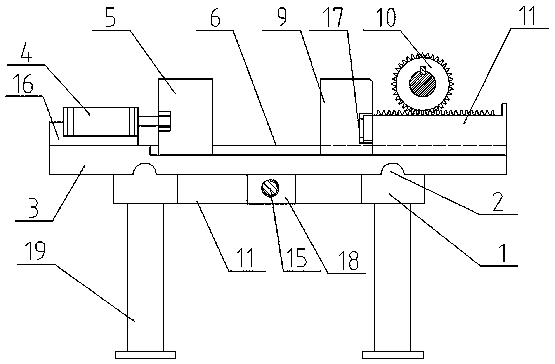

[0032] see Figure 1-3 , this embodiment provides a multi-directional adjustable automatic processing fixture, including a first bracket 1, a second bracket 3, a cylinder 4, a first clamping block 5, a second clamping block 9, a first motor 12, a second motor 14. Screw rod 15, leg 19; the lower part of the first bracket 1 is provided with a leg 19, the middle of the first bracket 1 is provided with a second motor 14, and the second motor 14 is fixedly connected to the screw rod 15; the second bracket 3 Set on the top of the first bracket 1, the first clamping block 5 and the second clamping block 9 are installed on the second bracket 3, the left side of the second bracket 3 is provided with a cylinder 4, and the cylinder 4 is installed on the cylinder support 16, and the cylinder The support 16 is fixedly connected to the second bracket 3, the cylinder 4 is fixedly connected to the first clamping block 5, and the first motor 12 is arranged on the right side of the second brack...

Embodiment 2

[0037] see see Figure 4 , the structure of this implementation is the same as that of Embodiment 1, the first clamping block 5 is replaced by the third clamping block 21, the second clamping block 9 is replaced by the fourth clamping block 22, the third clamping block 21 and the fourth clamping block 22 Compatible with cylindrical workpieces that can be clamped horizontally.

[0038] Working principle of the present invention:

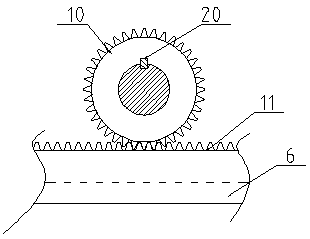

[0039] This embodiment provides a multi-directional adjustable automatic processing fixture, the first clamping block 5 and the second clamping block 9 are installed on the second guide rail 6, the cylinder 4 pushes the first clamping block 5 to the right, The rotation of the first motor 12 drives the gear 10 to rotate, the rack 11 pushes the second clamping block 9 to move to the left, the first clamping block 5 cooperates with the second clamping block 9 to clamp the workpiece, and the pressure sensor 17 senses that the clamping force reaches the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com