Multi-station automatic fixture rotating system

A multi-station and tooling technology, applied in positioning devices, metal processing, feeding devices, etc., can solve problems such as difficult clamping, low efficiency, affecting production efficiency and product processing quality, and achieve fast clamping speed and high production efficiency. The effect of high efficiency, wide use promotion value and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

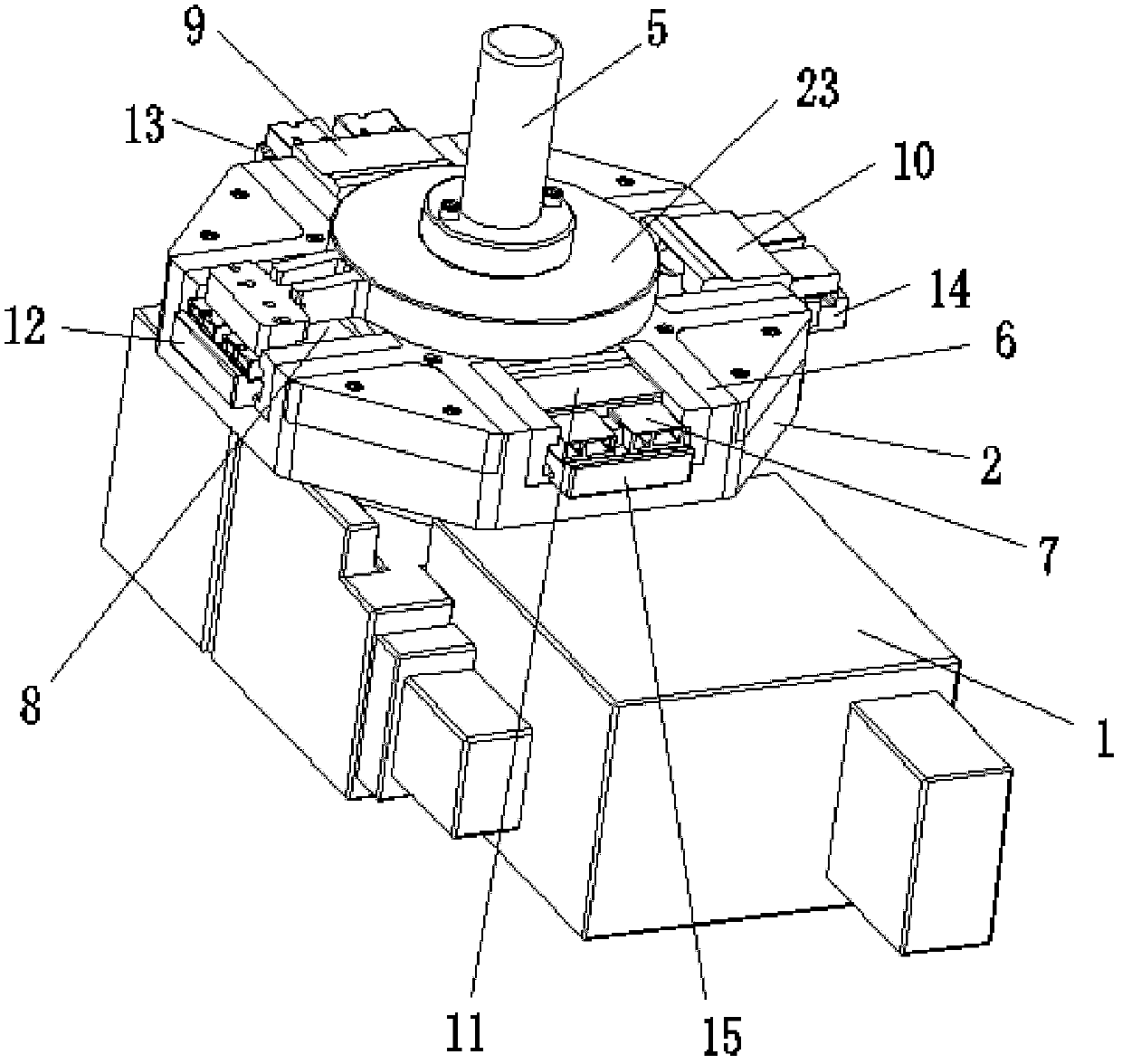

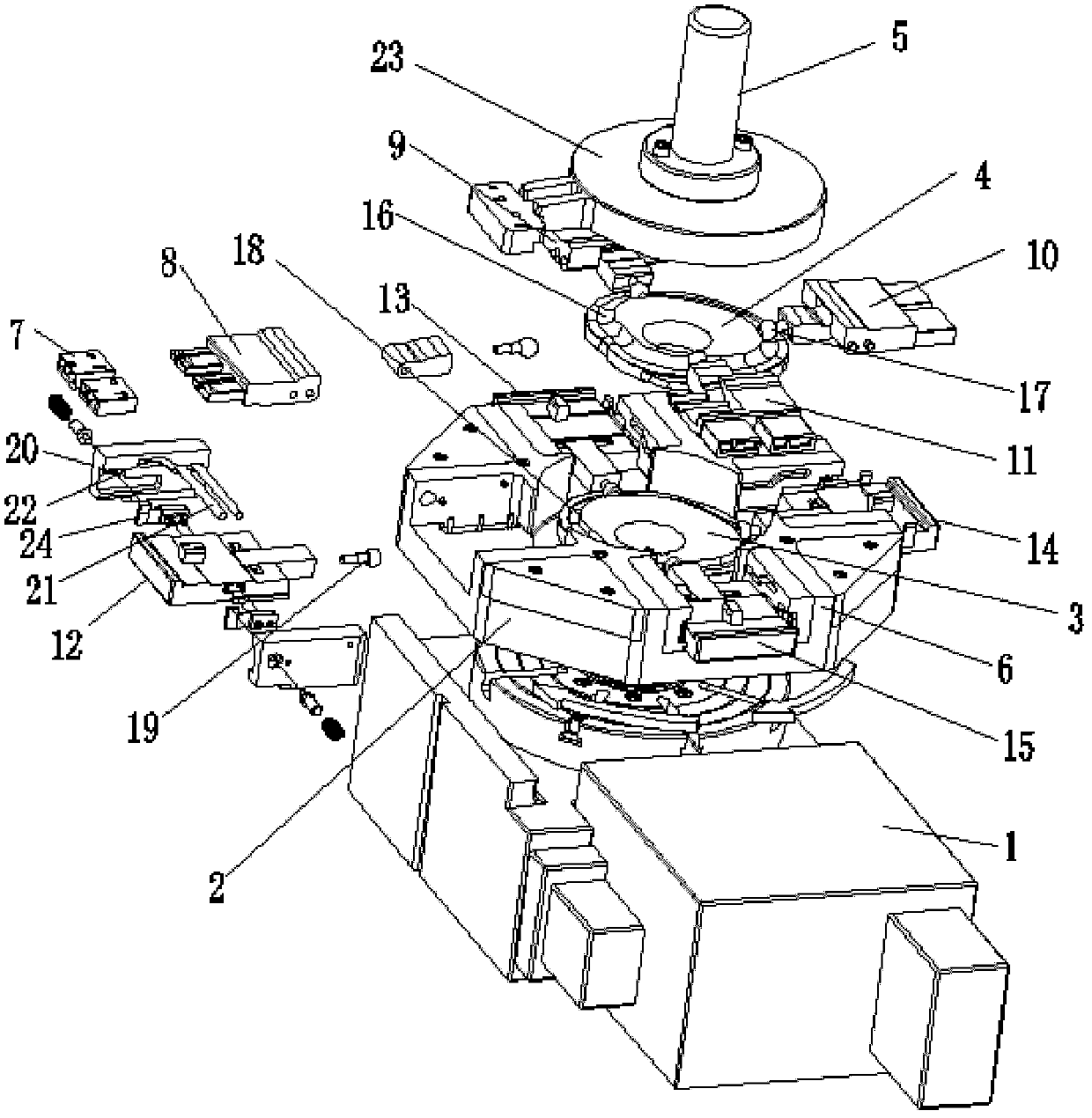

[0025] A multi-station automatic rotary tooling system, comprising a power mechanism 1, a rotating disk 2, a lower cam 3, an upper cam 4 and an oil cylinder 5, the upper cam and the lower cam are fixed on the on the cylinder shaft of the oil cylinder; the rotating disk and the oil cylinder are concentrically arranged under the lower cam, and the outer circumferences of the upper cam and the lower cam are sequentially set on the rotating disk, and the rotating disk is placed on the rotating disk. Driven by the power mechanism, it can rotate around the outer circumference of the upper cam and the lower cam respectively; in addition, a baffle plate 6 is provided on the rotating disk so that four station areas are formed at intervals above the rotating disk, and The first, second, third and fourth product clamps 8, 9, 10 and 11 for fixing the product 7 to be stamped are respectively provided on the cam corresponding to the four station areas, and the first, second, third and fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com