Rotary small-size paint spraying chamber convenient to move

A spray booth and rotary technology, applied in the spray booth, spraying device, etc., can solve the problems of large volume of spray booth, inconvenient movement, uneven spraying, etc., achieve uniform spraying, prevent precipitation, and solve the effect of uneven spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

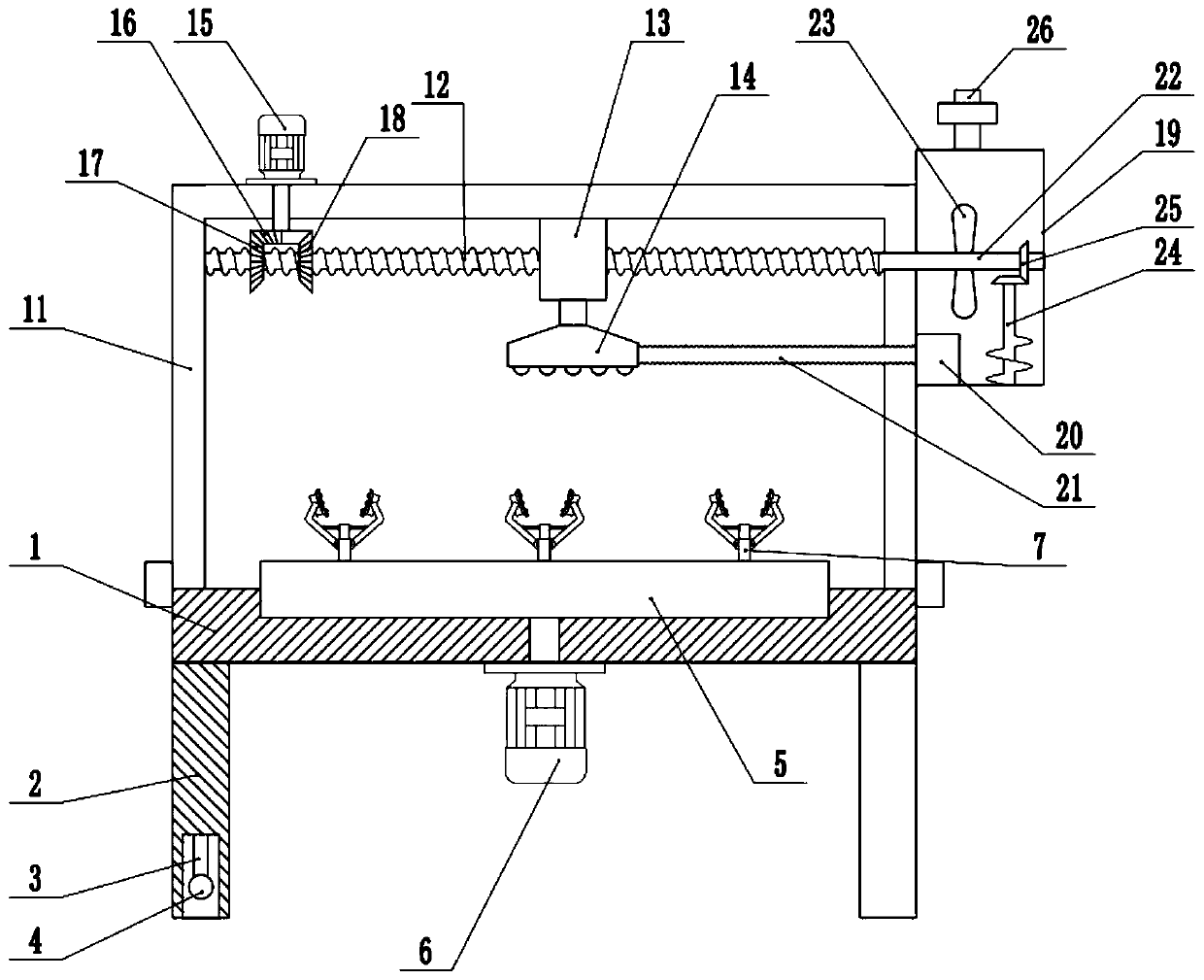

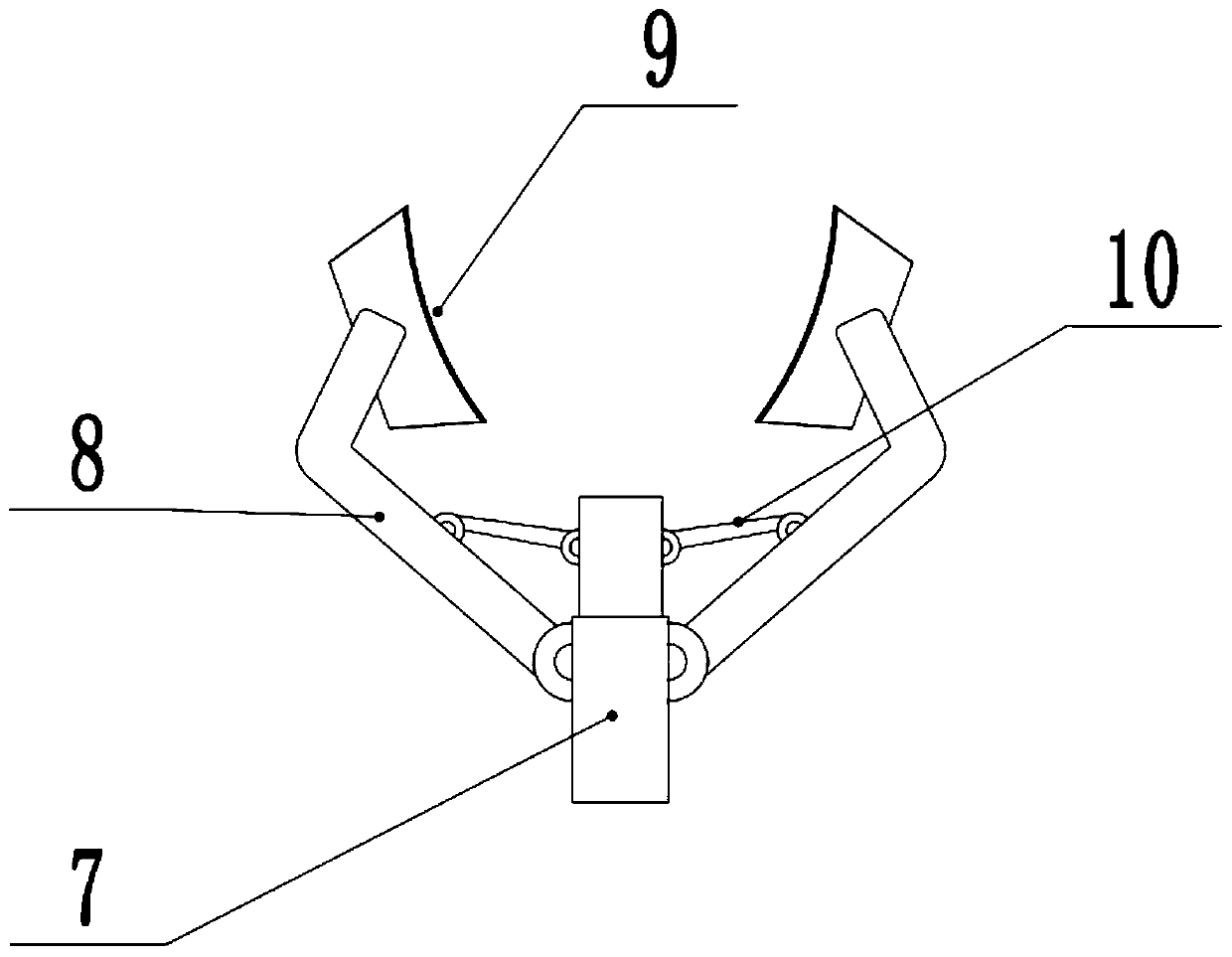

[0020] see Figure 1-3 , in the embodiment of the present invention, a kind of rotary small-sized spray booth that is convenient to move comprises workbench 1, nozzle 14, material storage box 19 and paint pump 20, and the upper surface of workbench 1 is connected with turntable 5 in rotation, and workbench 1 Rotary motor 6 is fixedly connected to the bottom of the rotary motor 6, and the shaft end of the rotary motor 6 passes through the workbench 1 to connect with the turntable 5. The rotary motor 6 can drive the turntable 5 to rotate. There are several clamping mechanisms distributed on the upper surface of the turntable 5. The holding mechanism includes a telescopic mechanism 7, jaws 8, a clamping plate 9 and a connecting rod 10. The lower end of the telescopic mechanism 7 is fixedly connected to the upper surface of the turntable 5, and both sides of the telescopic mechanism 7 are hinged with jaws 8. A clamping plate 9 is installed on the upper end of the jaw 8, and a conn...

Embodiment 2

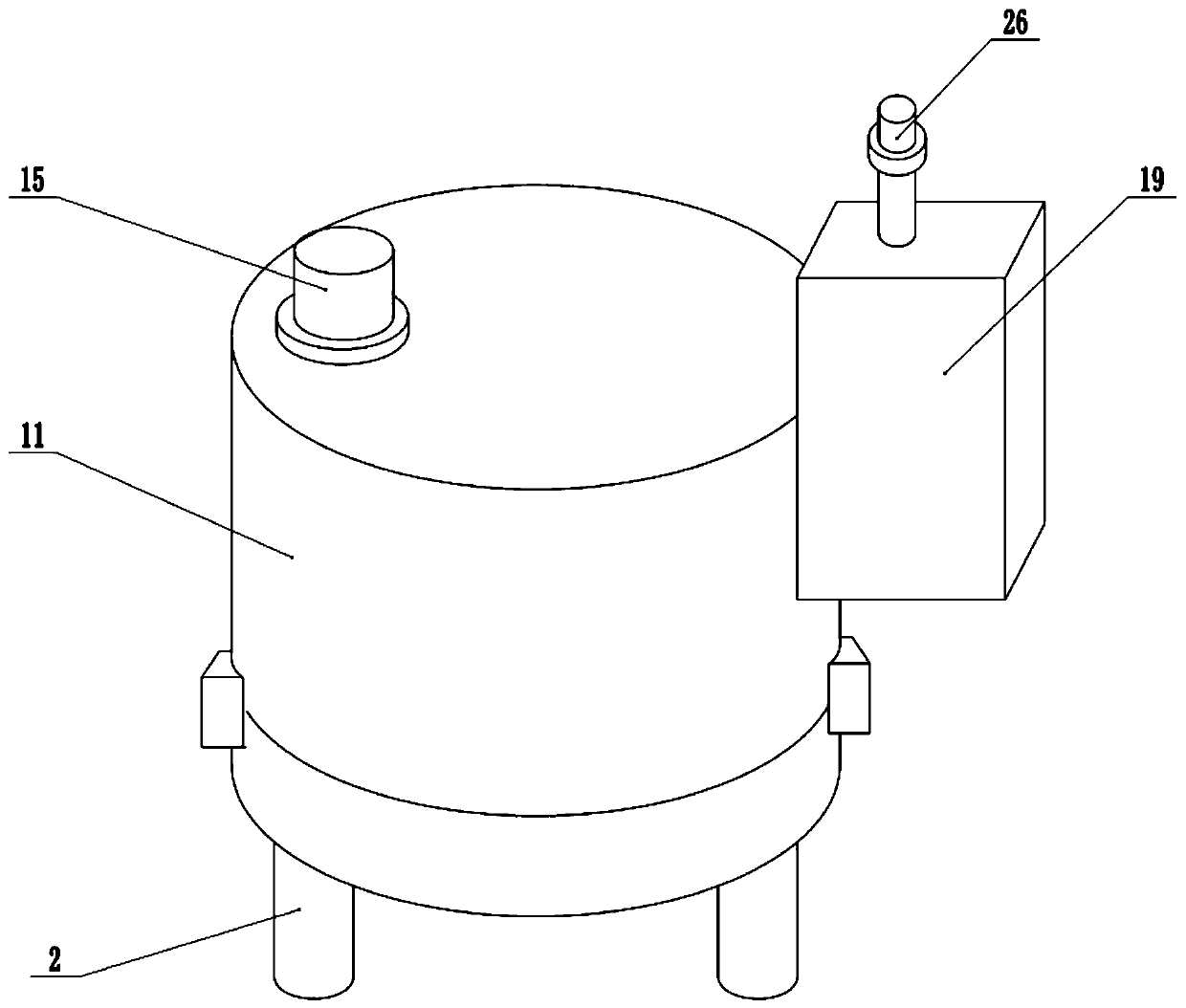

[0024] On the basis of Embodiment 1, a stirring mechanism is installed in the inside of the material storage box 19, and the stirring mechanism includes a rotating shaft 22, a stirring blade 23, a screw rod 24 and a bevel gear set 25, and one end of the rotating shaft 22 is connected with the screw mandrel 12, and the rotating shaft 22 The other end of the other end is rotationally connected with the side wall of the material storage box 19, and the rotating shaft 22 is fixedly connected with the stirring blade 23. When the screw mandrel 12 rotates, the stirring blade 23 is driven to rotate, and the stirring blade 23 is used to stir the paint to prevent the paint from depositing. The bottom of 19 is rotatably connected with screw rod 24, and the upper end of screw rod 24 is connected with rotating shaft 22 through bevel gear set 25. When rotating shaft 22 rotates, it drives screw rod 24 to rotate, and utilizes screw rod 24 to stir the bottom paint, further preventing the paint f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com