Workpiece-pressing jig

A fixture and workpiece technology, applied in the field of fixtures, can solve the problems of time-consuming and labor-intensive use, affecting the clamping speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better illustrate the technical solution of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

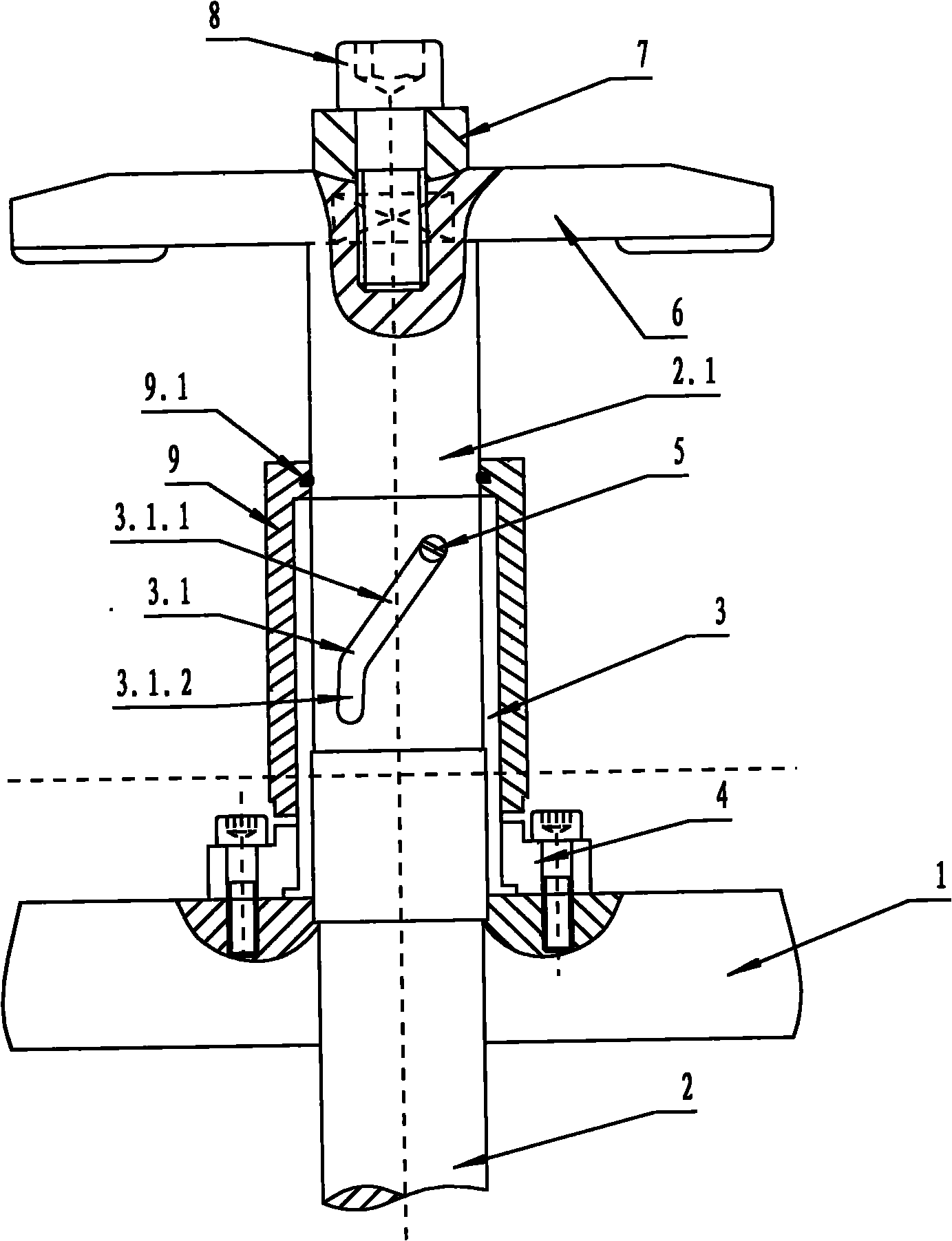

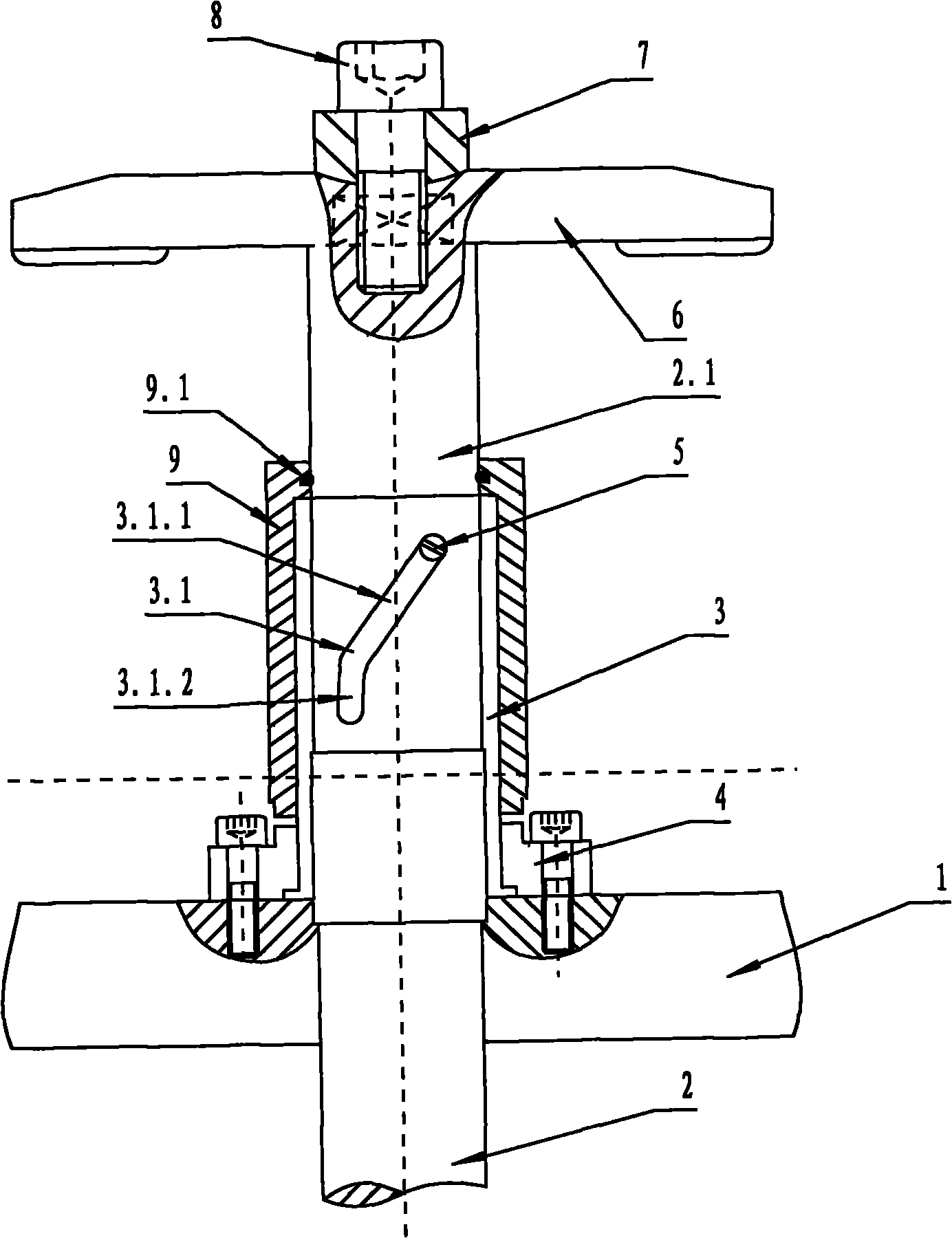

[0014] As shown in the drawings, a work piece pressing fixture includes a fixture table 1, a cylinder 2 and a pressure plate 6, and also includes a guide sleeve 3, a fixed seat 4, a guide pin 5 and a locking device for the pressure plate. The guide sleeve 3 is mounted on the cylinder 2 On the cylinder shaft 2.1, the fixed seat 4 fixes the guide sleeve 3 on the fixture table 1, the guide sleeve 3 has a guide groove 3.1, and the guide groove 3.1 has a spiral groove portion 3.1.1 and a straight groove portion 3.1.2, A quarter of the circumference of the cylinder shaft spanned by the helical groove, the guide pin 5 passes through the guide groove 3.1 and is fixed on the cylinder shaft 2.1, the guide sleeve 3 is also provided with a cover 9 outside, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com