Double formwork quick injection molding machine

An injection molding machine and double-platen technology, which is applied in the field of double-platen rapid injection molding machines, can solve the problems of long moving distance of the integrated oil cylinder, large amount of oil required for the oil circuit, and easy failures, etc., to achieve beautiful appearance and configuration, and reduce floor space , the effect of reducing the amount of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

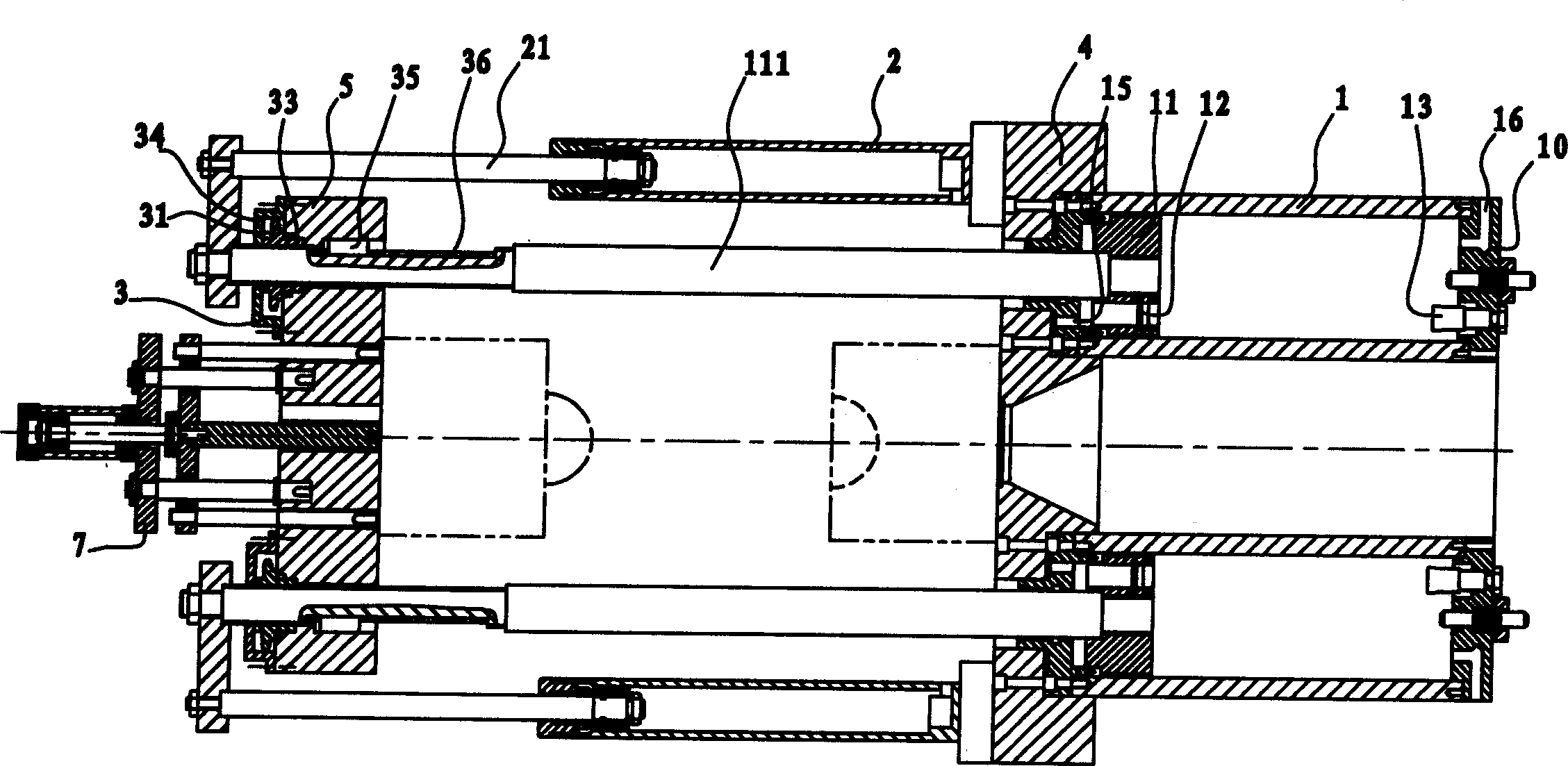

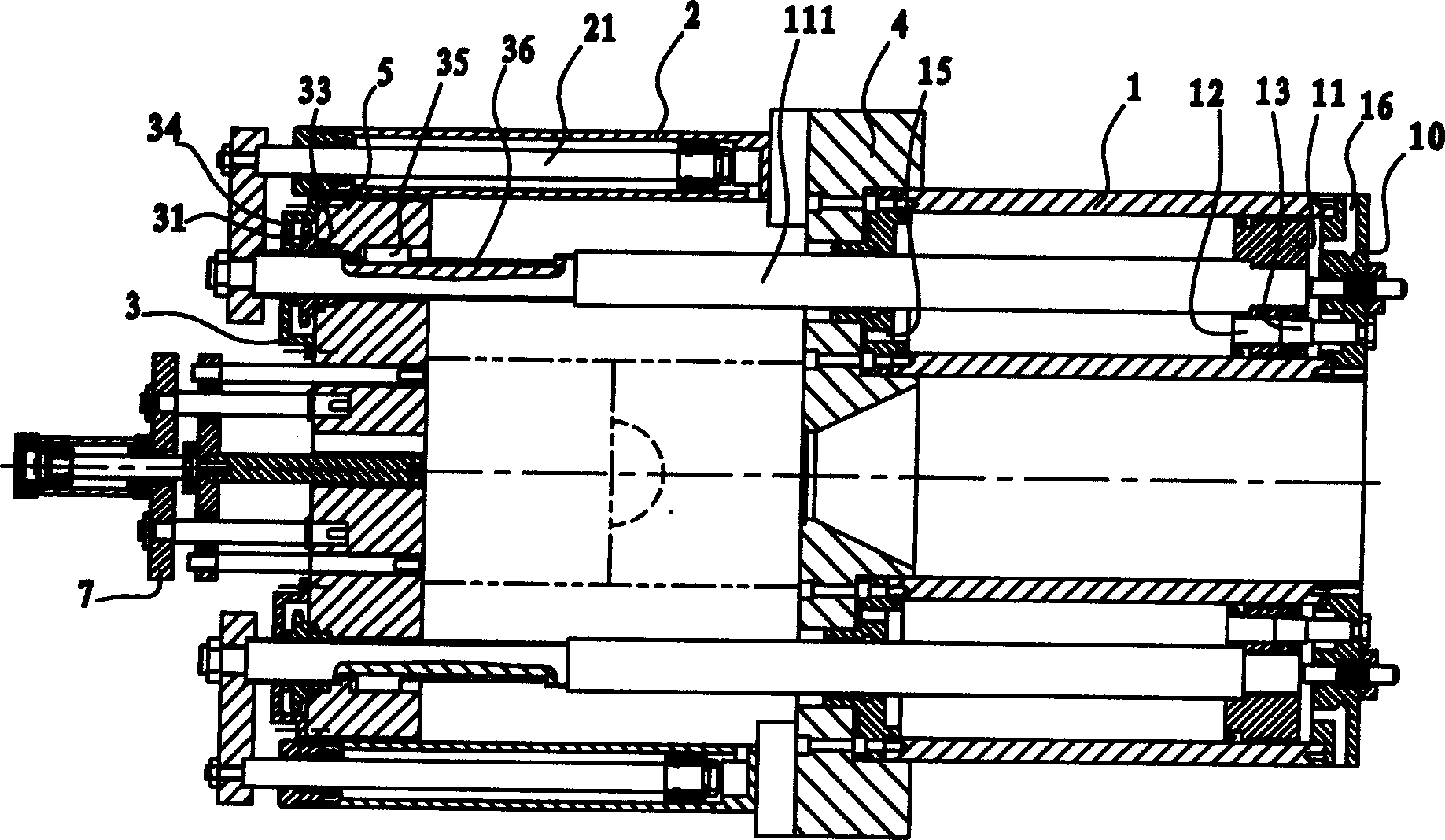

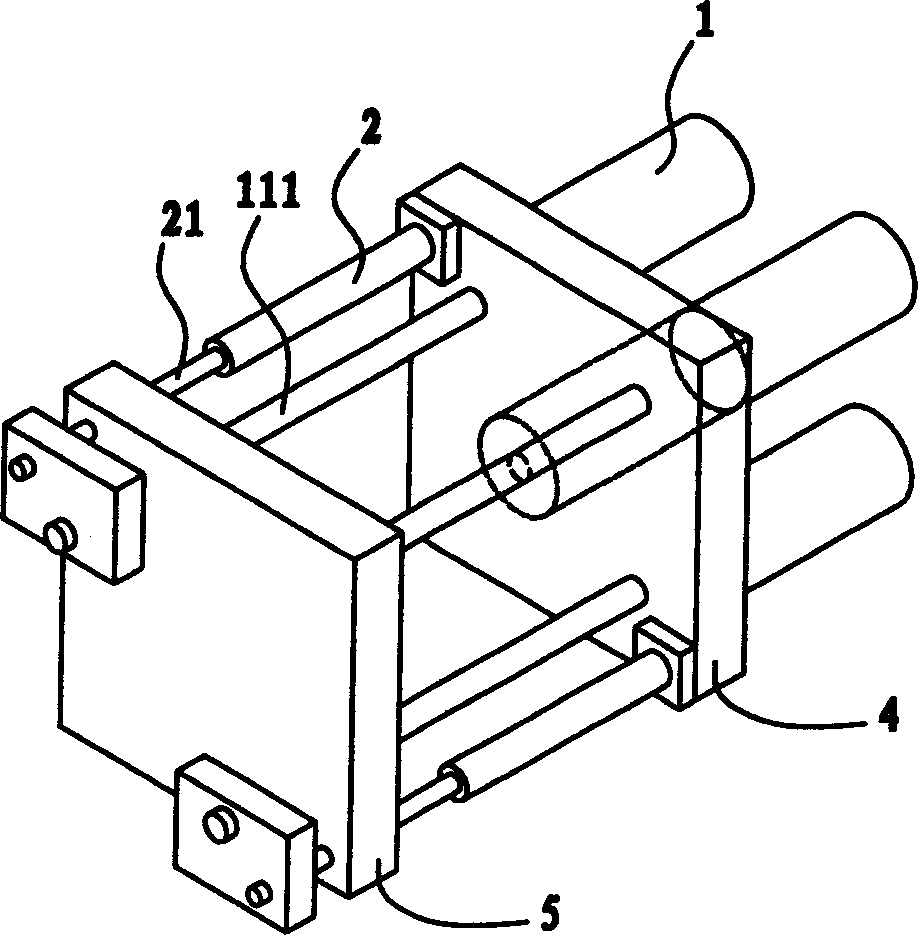

[0033] refer to figure 1 and 2 , there are only two templates of the double-platen rapid injection molding machine, and the structure is simplified. One of the installation methods of the templates and related devices and mechanisms is to fix the fixed template 4 and the injection device on the frame, and the injection port of the injection device is placed in the center of the fixed template 4. , the lower end of the moving template 5 and the frame have a sliding support structure so that the moving template 5 can move horizontally smoothly. The sliding supporting structure, frame and injection device are well known to those skilled in the art and are not shown. Clamping oil cylinder 2 and clamping oil cylinder 1 can be installed on one template or respectively on two templates. In this embodiment, they are respectively fixed on both sides of fixed template 4 and connected with low pressure and high pressure oil circuits respectively. The piston rod 111 of the mold clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com