Chuck suitable for irregular part

A technology for irregular parts, applied in the field of chucks for irregular parts, it can solve the problems that the workpiece cannot be clamped reasonably, affects the processing accuracy, and the clamping speed is slow, and achieves simple structure, guaranteed processing quality, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

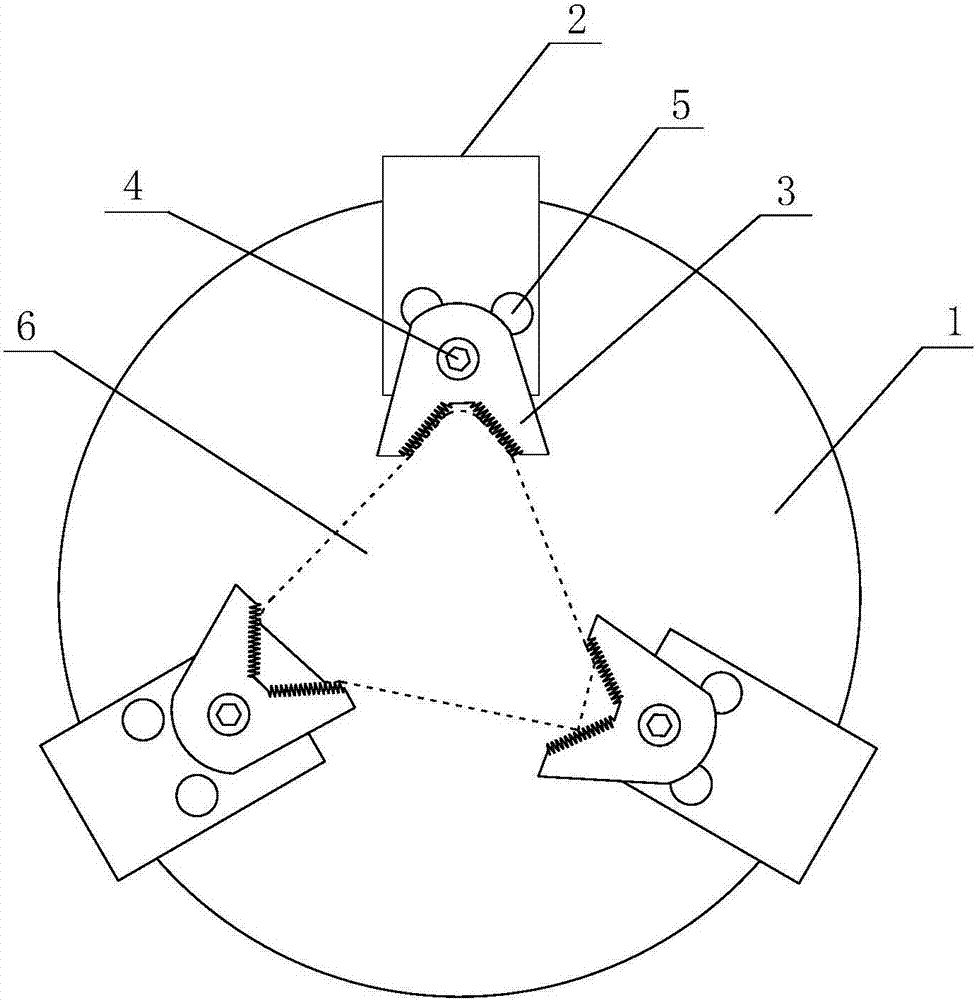

[0014] Such as figure 1 As shown, the present invention provides a chuck suitable for irregular parts, including a chuck body 1, a plurality of jaws 2 located on the chuck body 1, the number of jaws 2 is not limited, here 3 The claws 2 are taken as an example to make a specific description, and the claws 2 are evenly arranged on the chuck body 1 respectively.

[0015] The jaws 2 are respectively provided with jaws 3, that is, each jaw 2 has a jaw 3, the jaws 3 are V-shaped, and the clamping surface of the jaws 3 in contact with the part 6 is provided with Tooth lines, elastic gaskets can also be set; the jaw 3 is connected with the jaw 2 through the locking bolt 4, the jaw 3 is provided with a connecting hole, and the jaw 2 is provided with a threaded hole 5 matching the connection hole, and the threaded hole 5 can be multiple, and according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com