Special clamp suitable for L-shaped valve body machining and machining method

A special fixture and valve body technology, applied in the field of hydraulic parts processing, can solve the problem of frequent replacement of fixtures, and achieve the effect of shortening processing time, small size and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

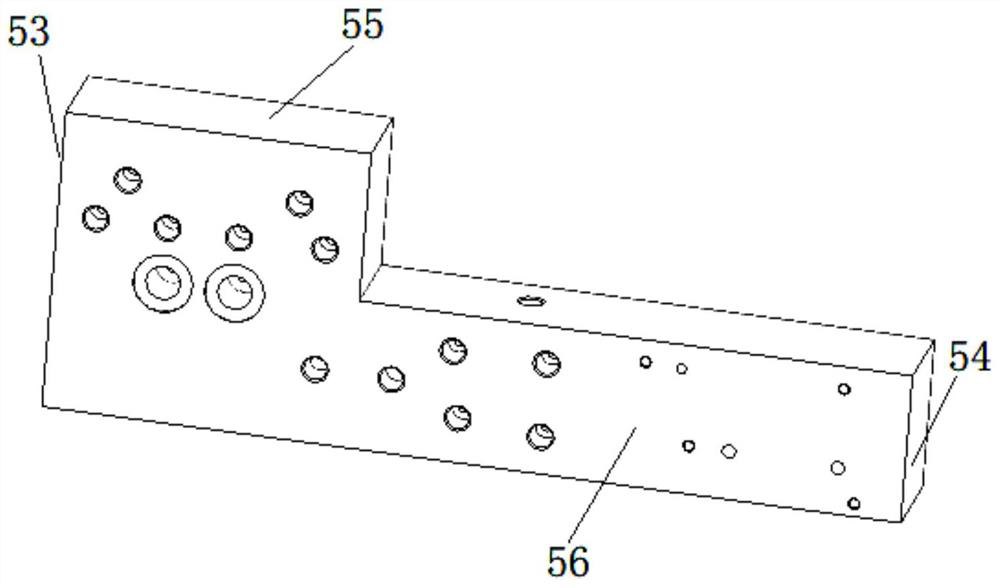

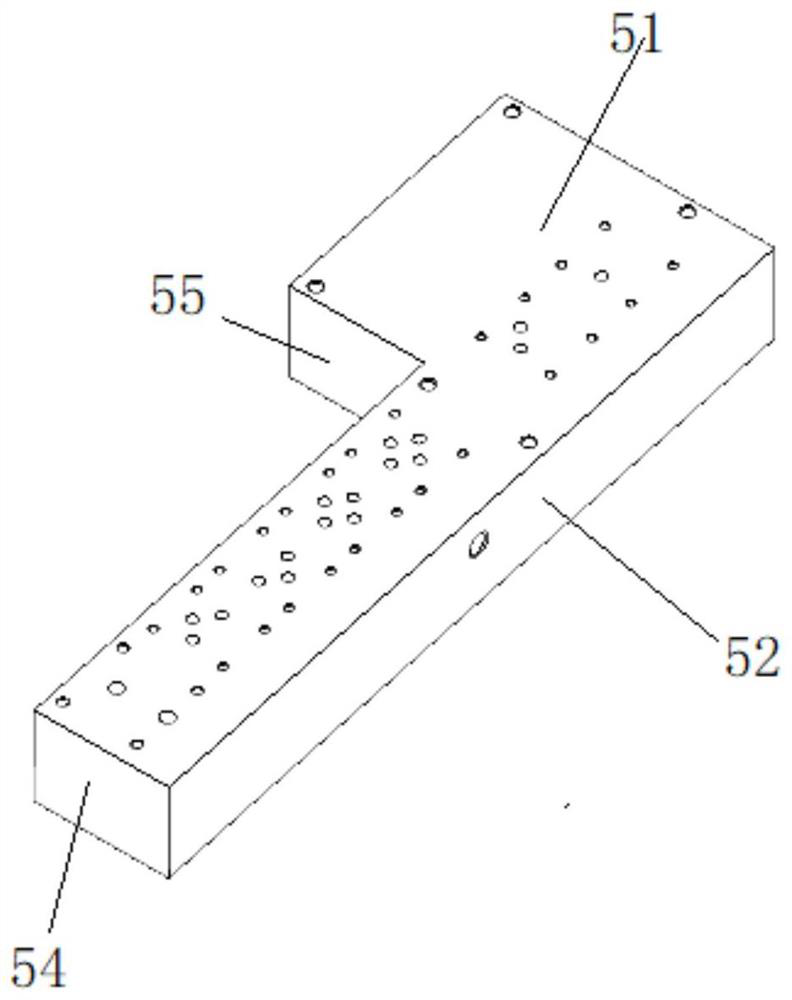

[0051] Embodiment 1: see Figure 1-11 , a special fixture suitable for L-shaped valve body processing. The fixture is used in a crane and can clamp two L-shaped valve bodies 5 at the same time. The L-shaped valve body 5 is provided with a second back 51 and a second front 56 opposite to each other. , the second top surface 55 , the second left side 53 , the second bottom surface 52 , and the second right side 54 connected end to end.

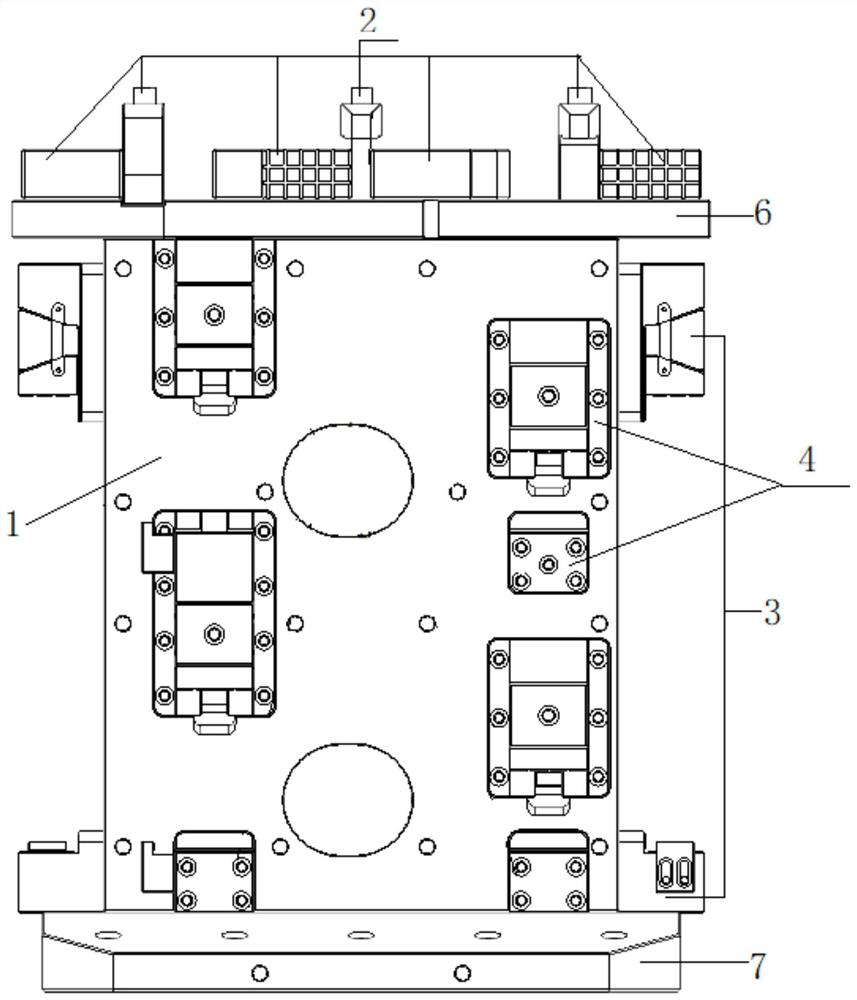

[0052]The special fixture suitable for L-shaped valve body processing includes a main body 1 , a set of first clamping assemblies 2 , two sets of second clamping assemblies 3 and a set of third clamping assemblies 4 . The first clamping assembly 2 includes a pressing plate 21 and a first positioning block 22 . The second clamping assembly 3 includes a first adjustment seat 31 and a second positioning block 32 . The third clamping assembly 4 includes a second adjustment seat 42 and a third positioning block 41 .

[0053] The main body 1 is int...

Embodiment 2

[0062] Embodiment 2, a processing method suitable for the L-shaped valve body 5, the fixture in this embodiment can be divided into three processes during processing to process the L-shaped valve body 5 in all directions, and the processing of the L-shaped valve body 5 Methods include:

[0063] Step 1: Place two L-shaped valve bodies 5 horizontally on the first clamping assembly 2, the second back surfaces 51 of the two L-shaped valve bodies 5 are positioned by the first pressure plate 211 and the two lever-type pressure plates 212, L The second left side 53 and the second bottom surface 52 of the L-shaped valve body are positioned by three first positioning blocks 22, and the second top surface 55 of the L-shaped valve body 5 can be processed after the positioning is completed;

[0064] Step 2: Place the L-shaped valve body 5 processed in Step 1 on two sets of second clamping assemblies 3 , and the second clamping assemblies 3 position the L-shaped valve body 5 on the two fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com