Patents

Literature

51results about How to "Improve scrolling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

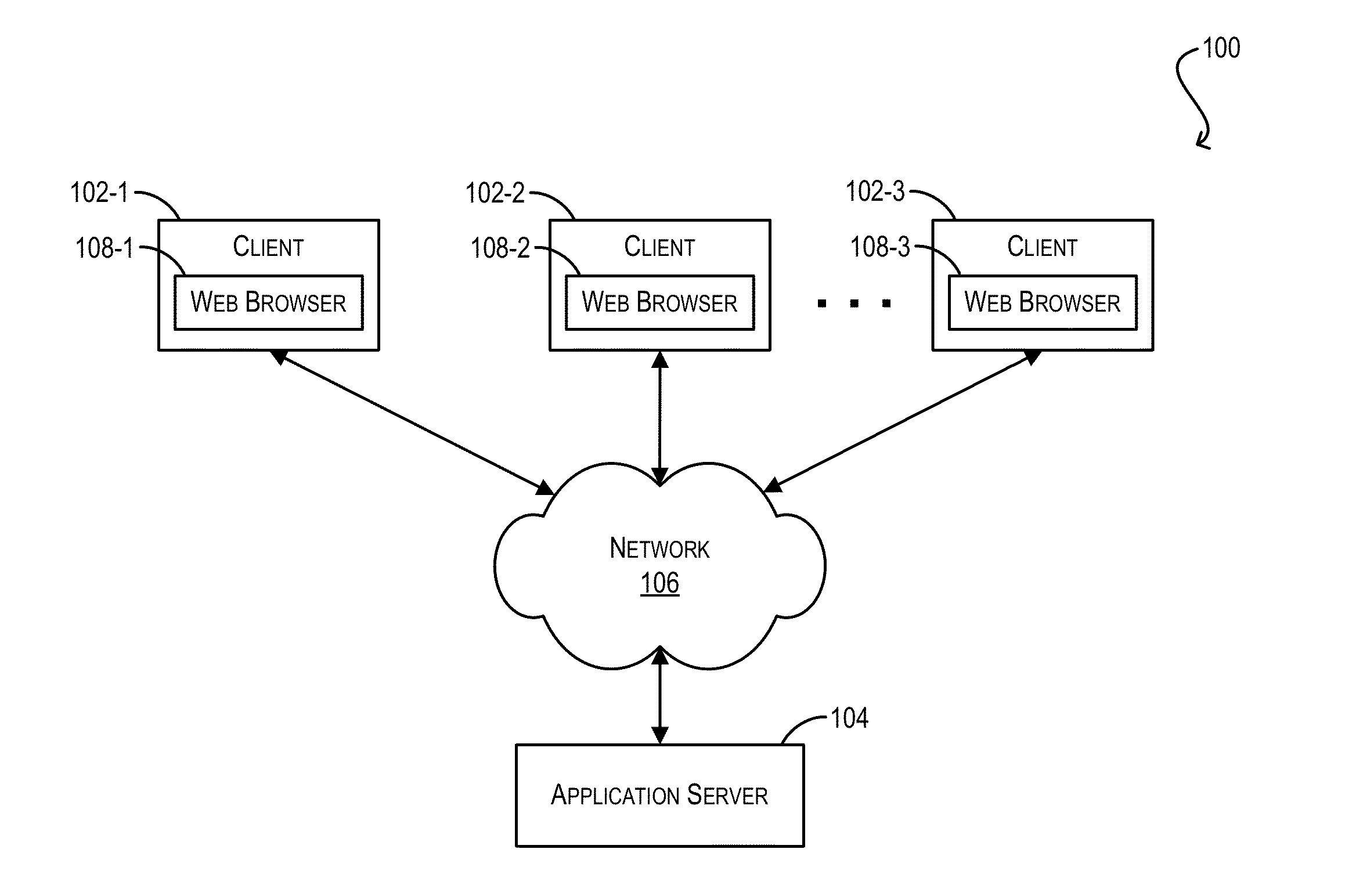

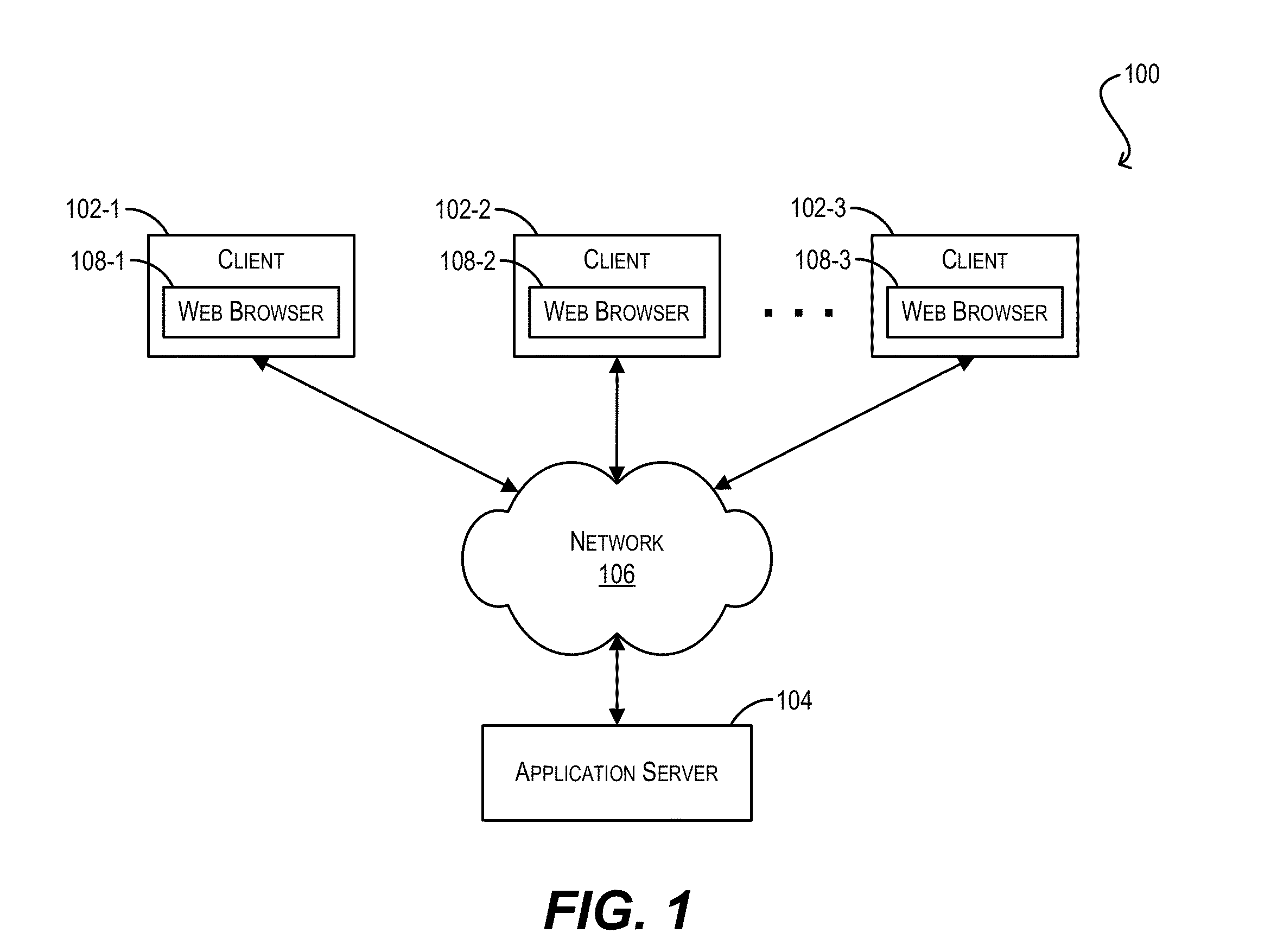

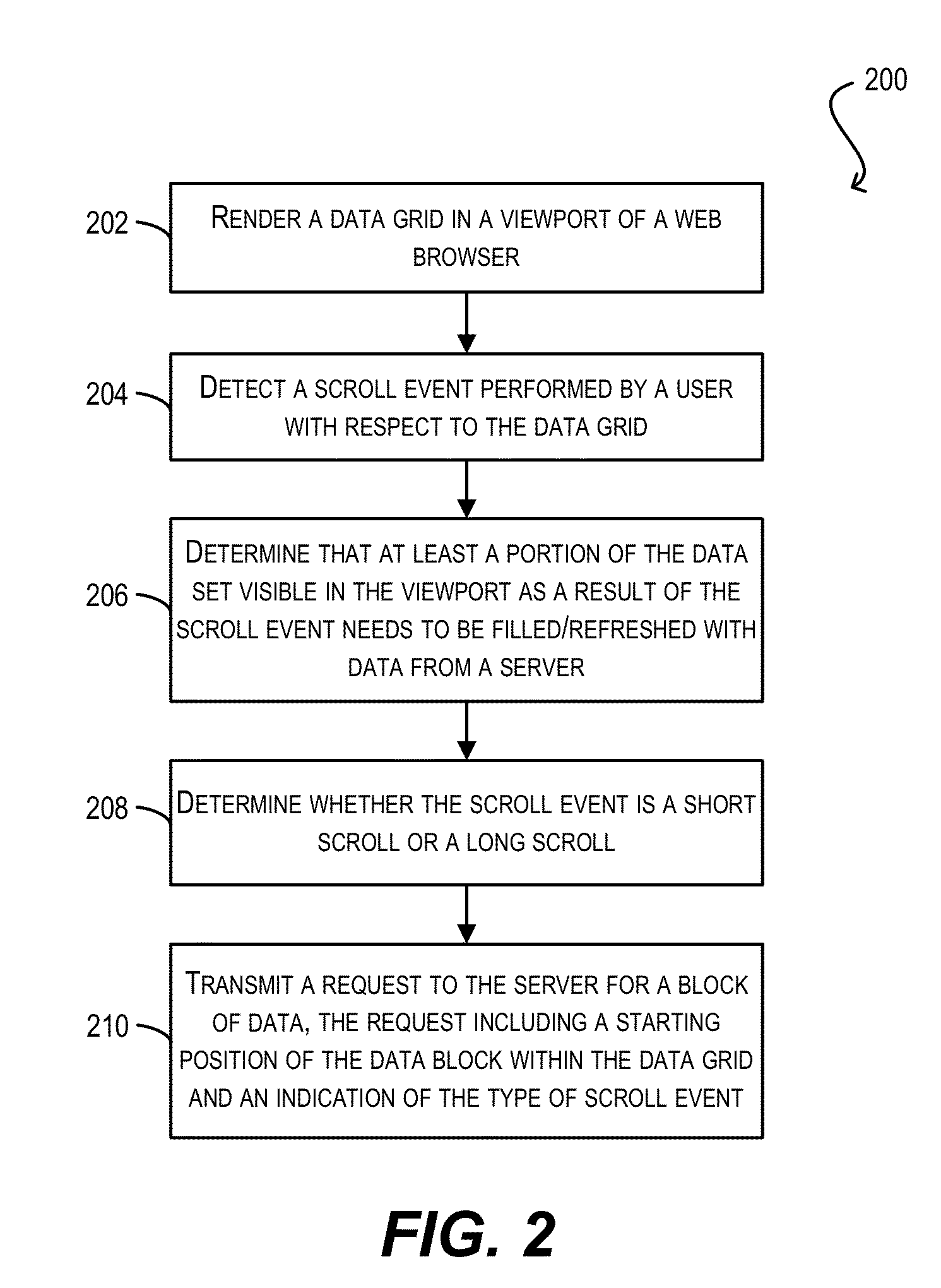

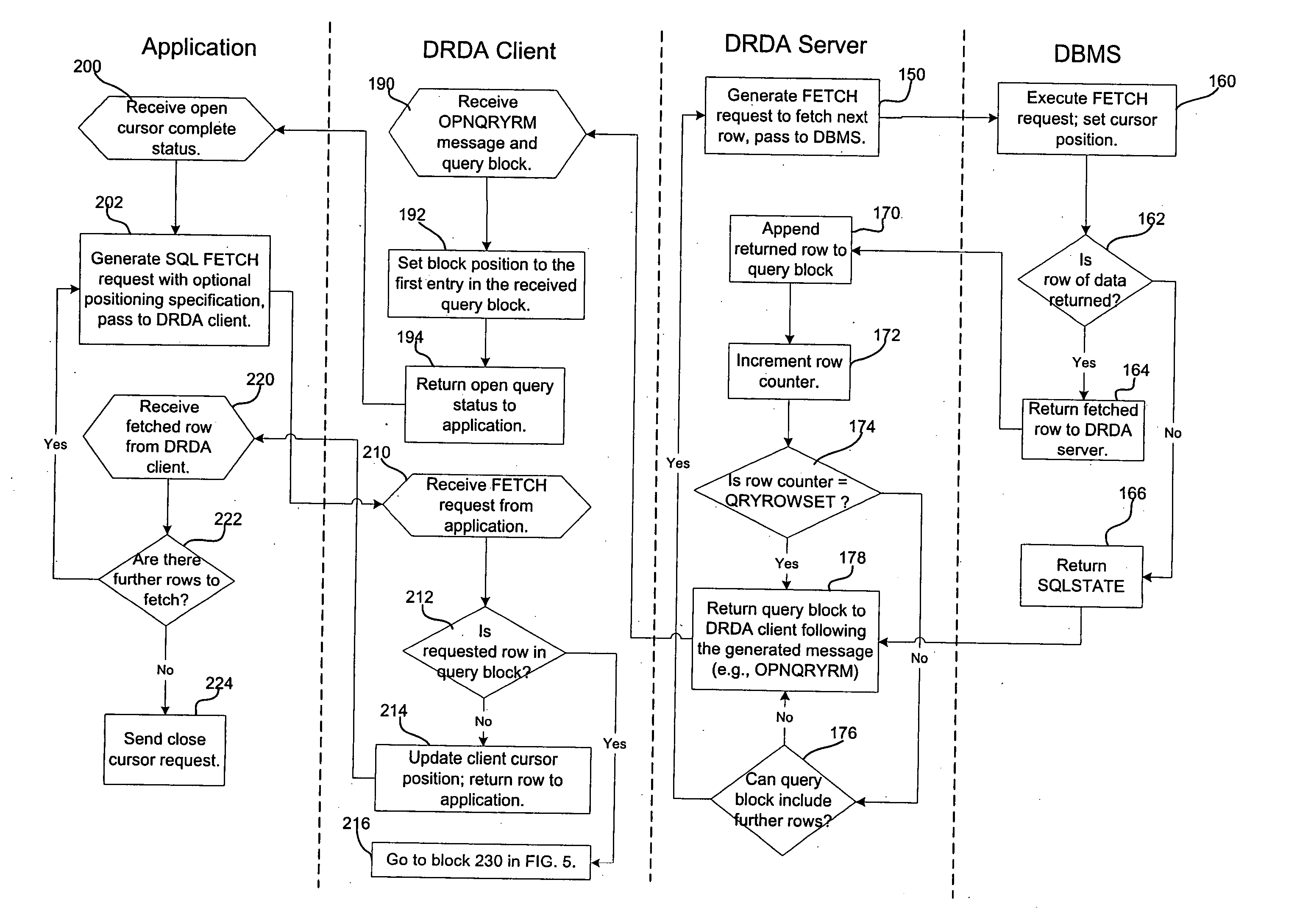

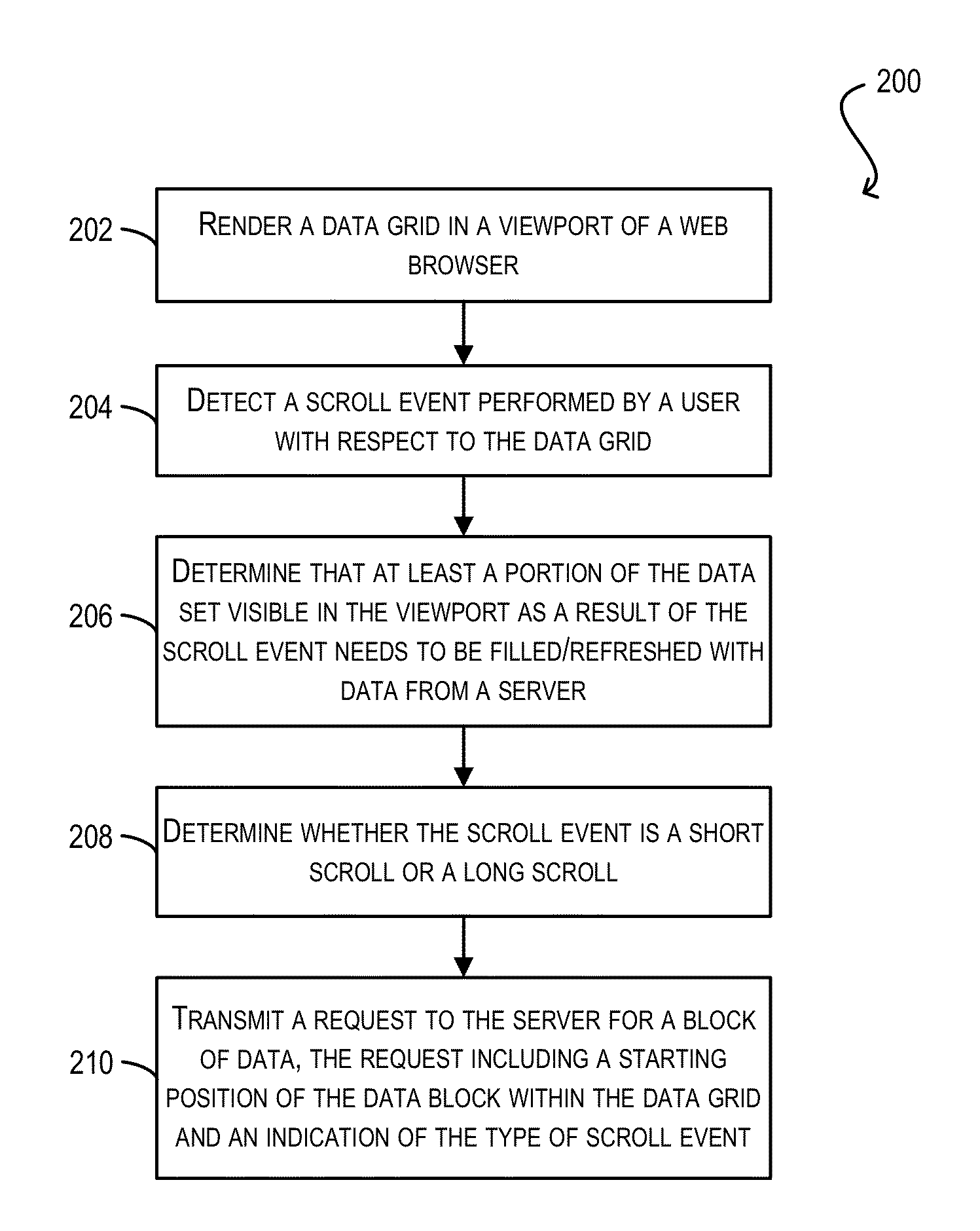

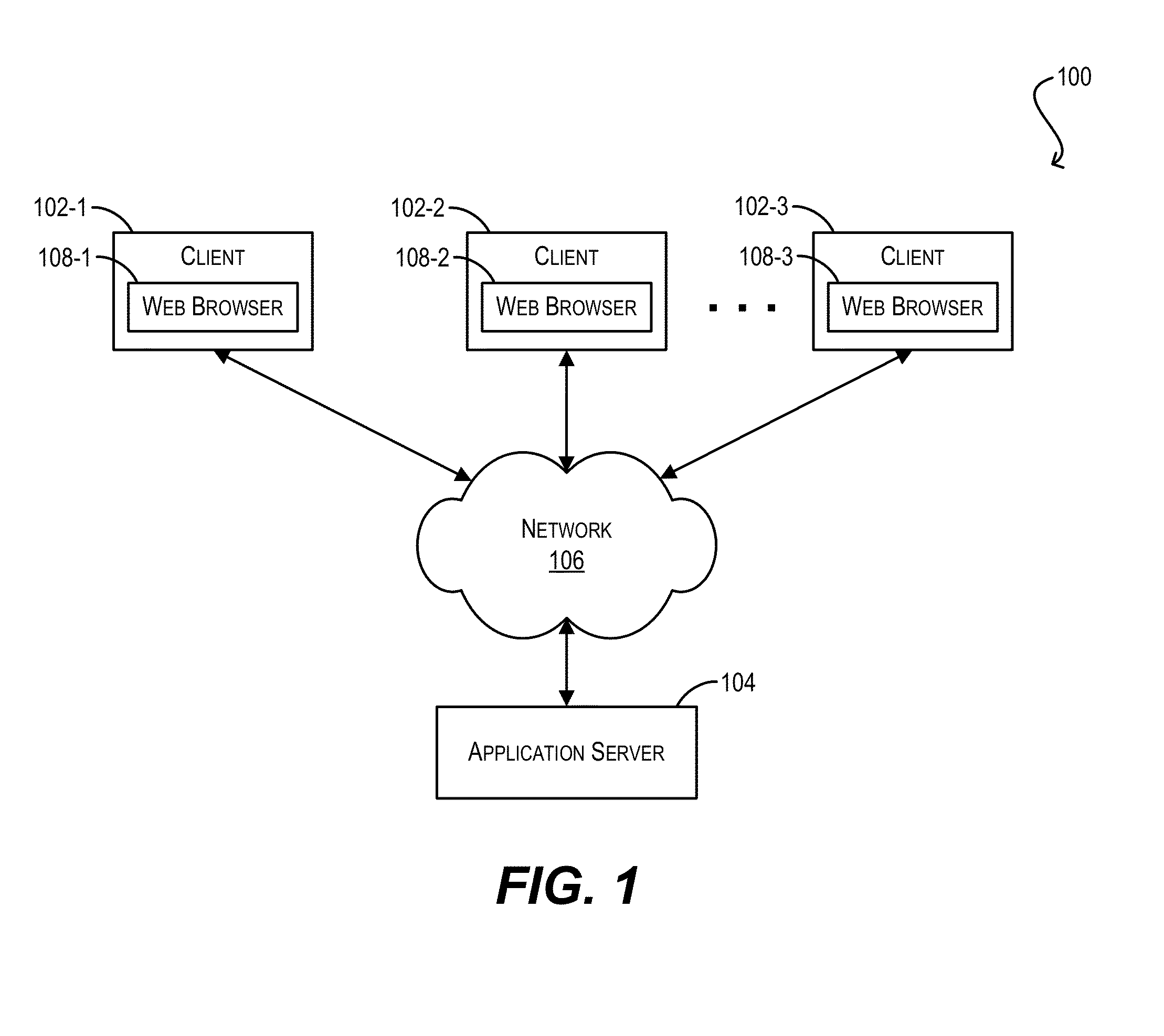

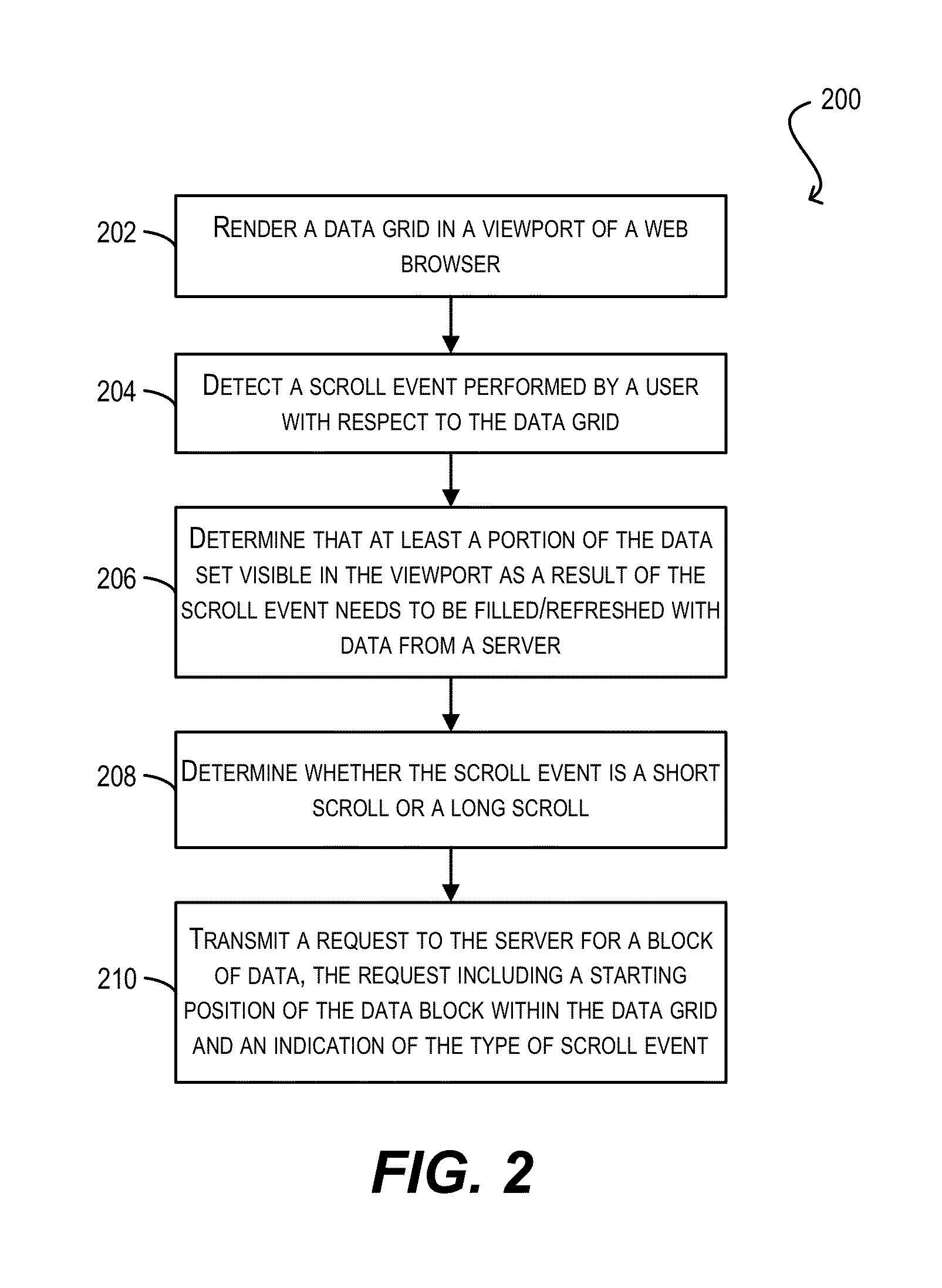

Eager block fetching for web-based data grids

ActiveUS20130103738A1Improve scrolling effectDelay minimizationInterprogram communicationMultiple digital computer combinationsWeb browserEvent type

Techniques for improving scrolling performance in a web-based data grid. In one set of embodiments, when a user scrolls through a data grid rendered in a viewport of the user's web browser, client-side code executing in the web browser can detect whether a scroll event has occurred that requires a portion of the viewport to be filled / refreshed with data from a server. The client-side code can further determine whether the scroll event is a short scroll or a long scroll, and can send a request to the server that indicates the type of scroll event. If the scroll event is a short scroll, the server can determine a first amount of data to fetch based on one or more first parameters. If the scroll event is a long scroll, the server can determine a second amount of data to fetch based on one or more second parameters.

Owner:ORACLE INT CORP

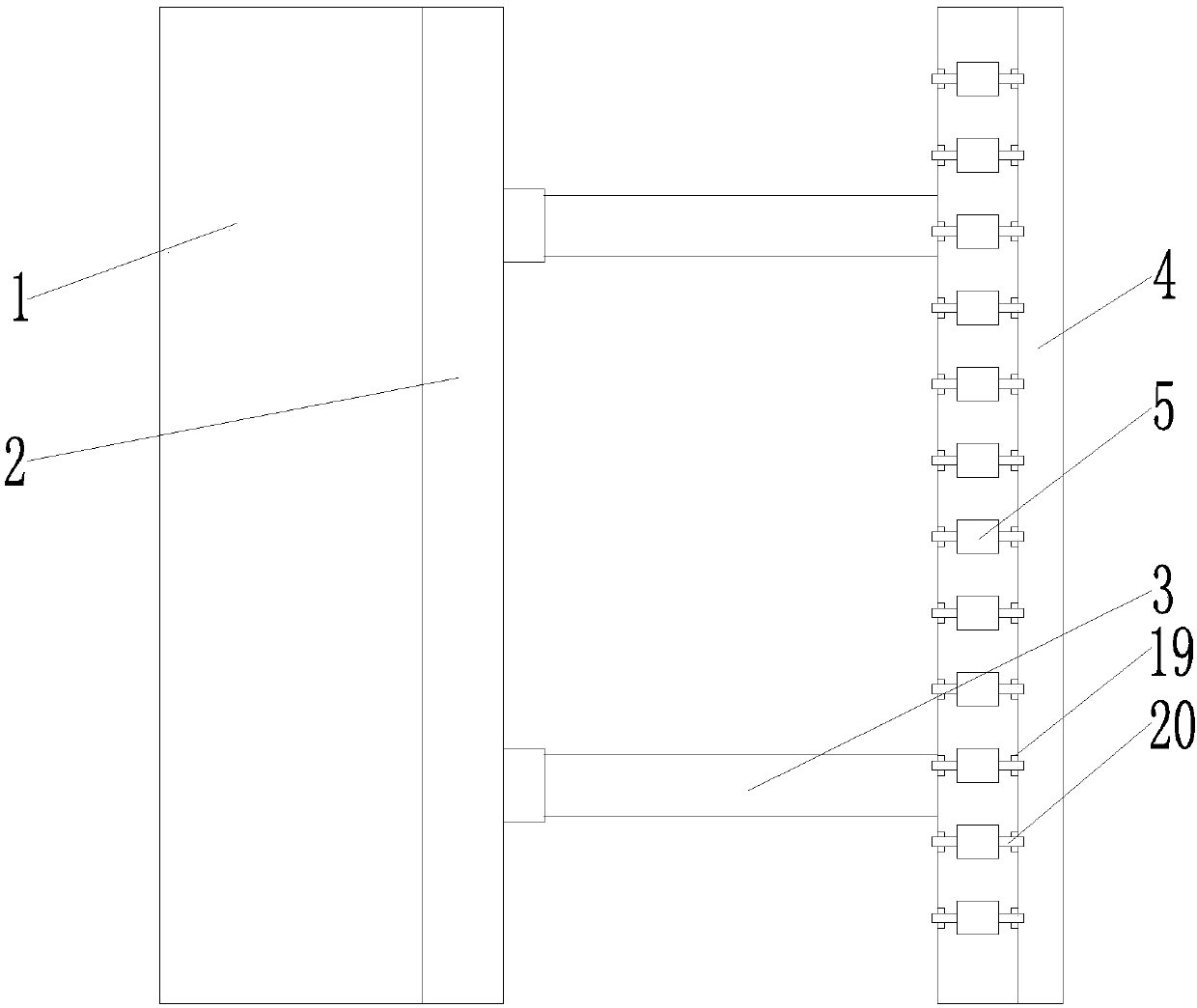

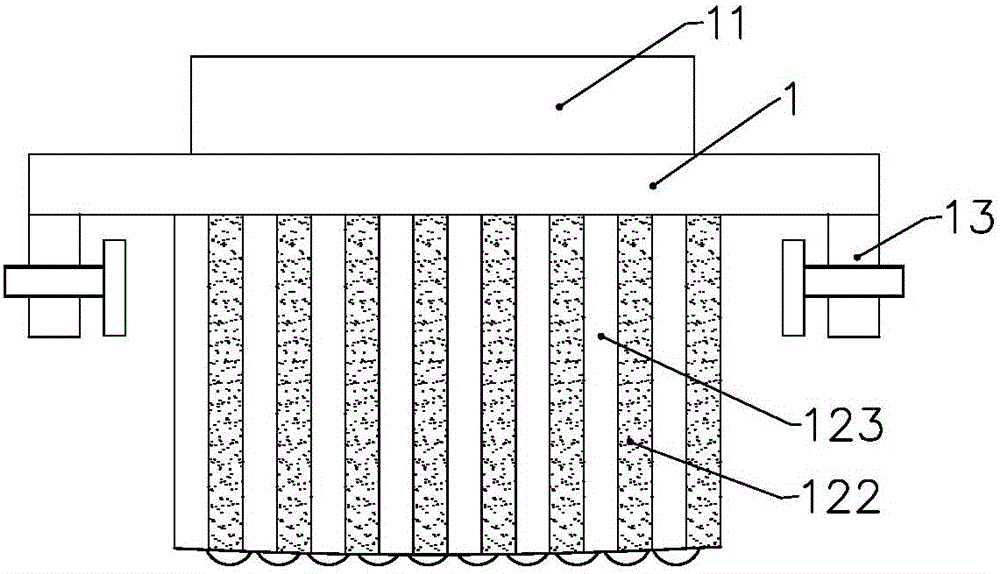

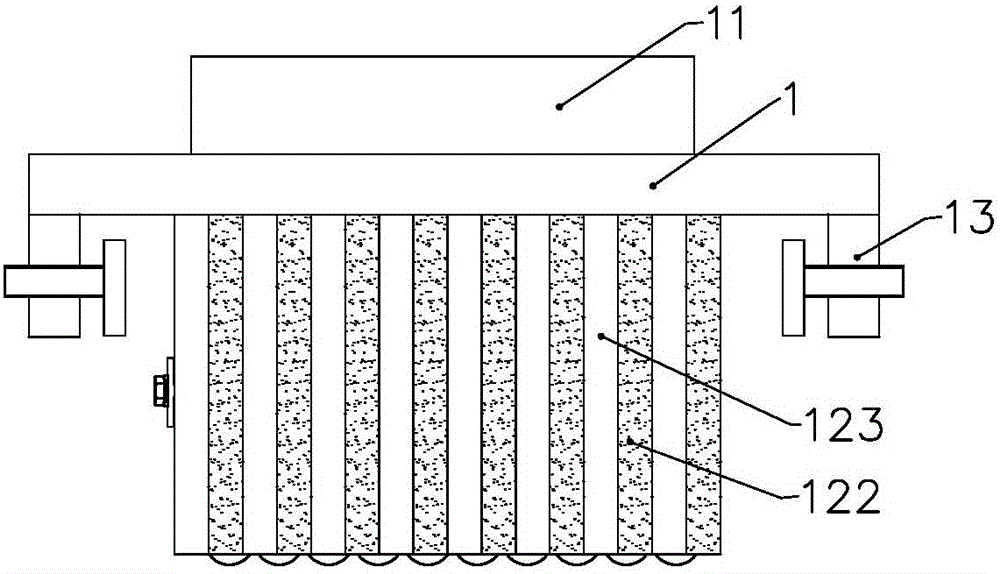

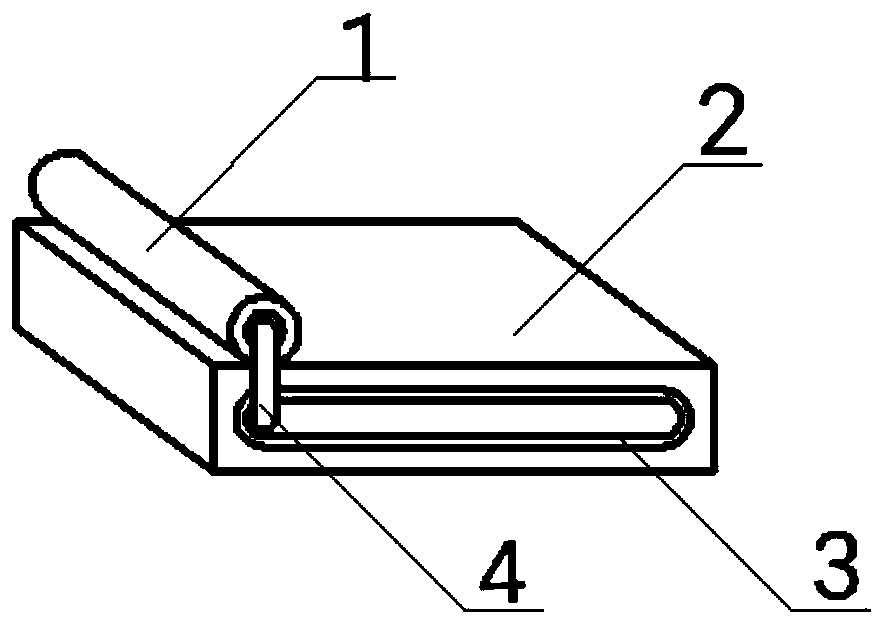

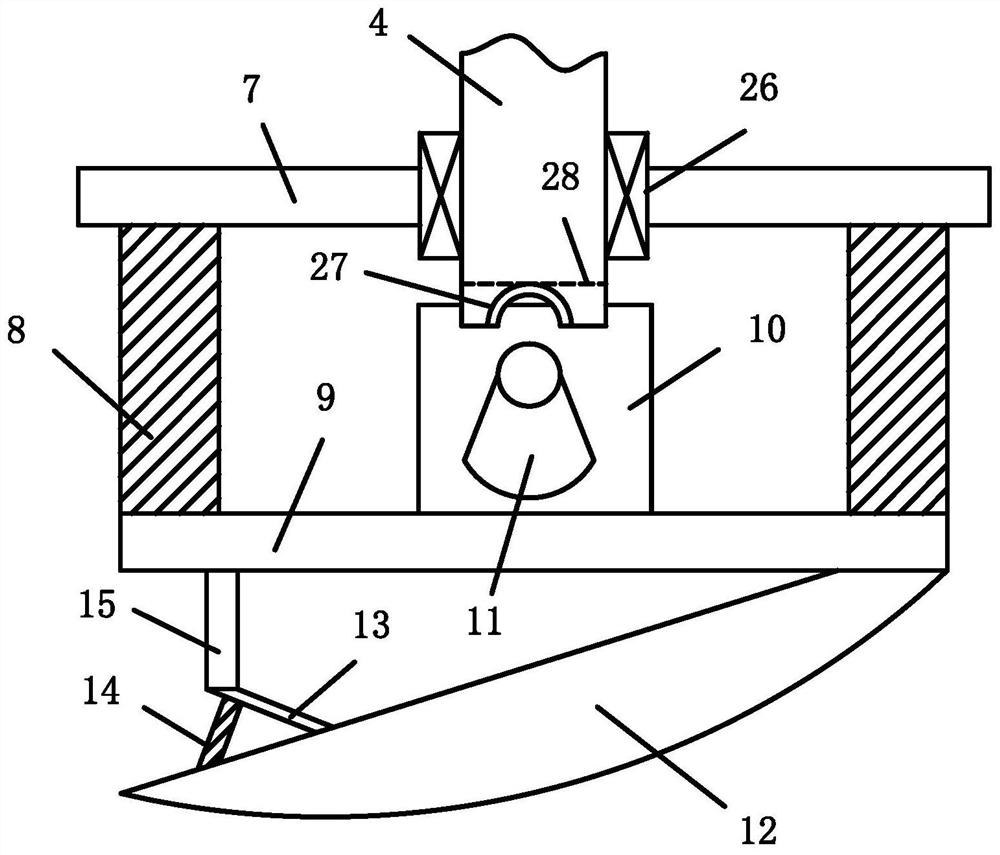

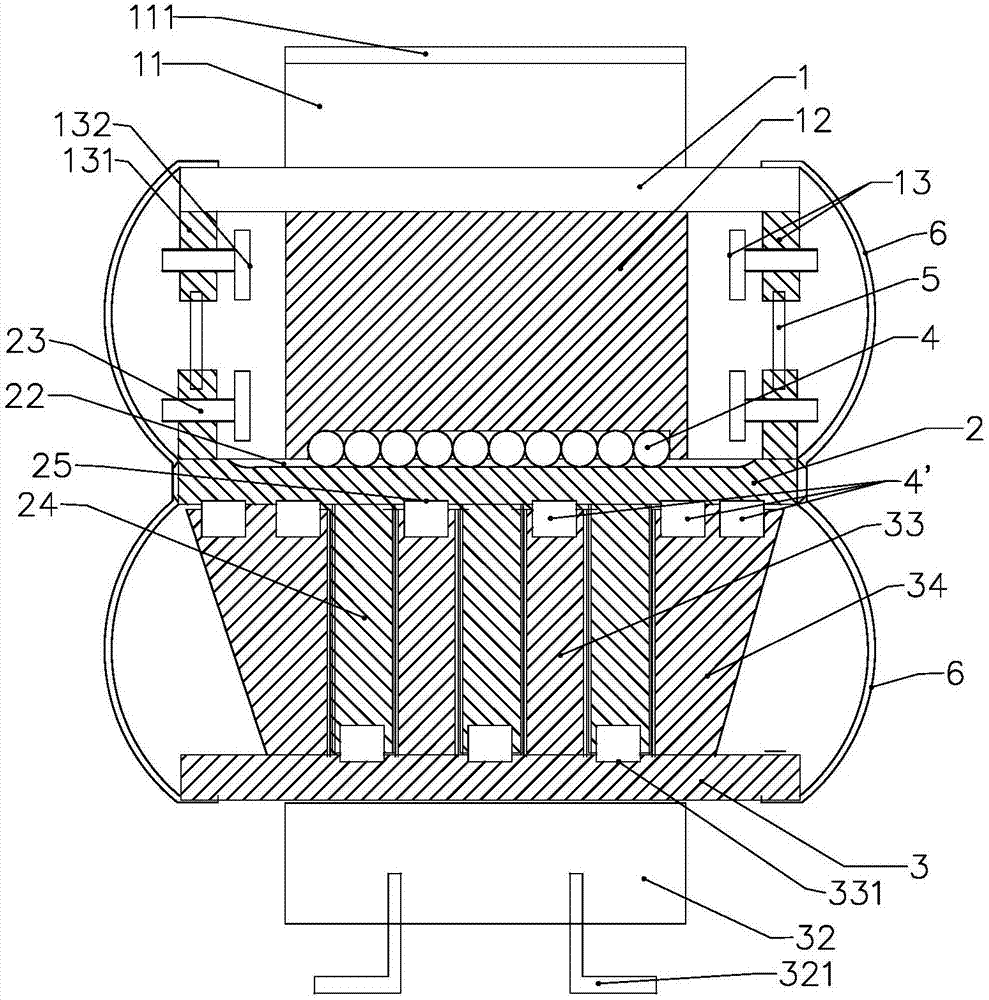

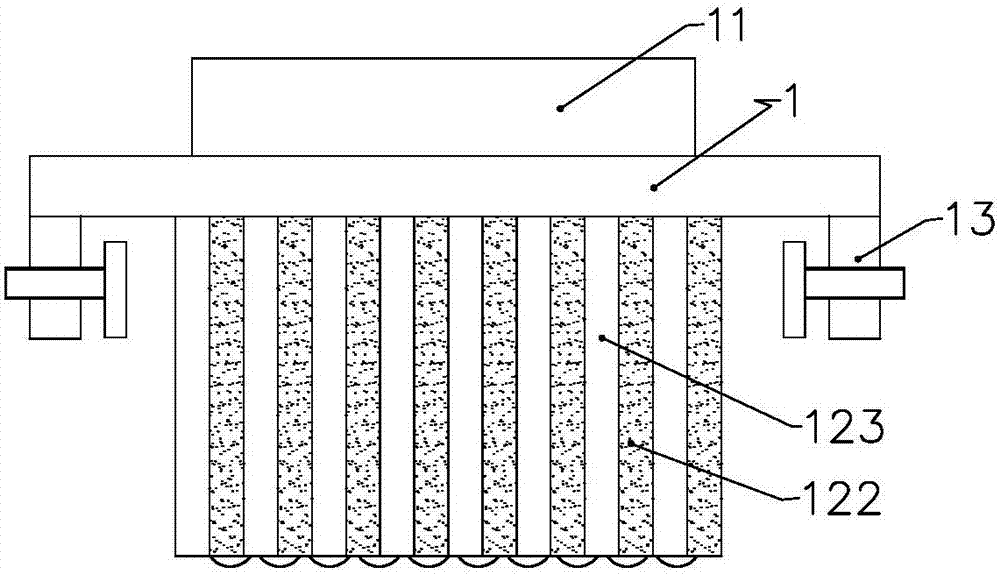

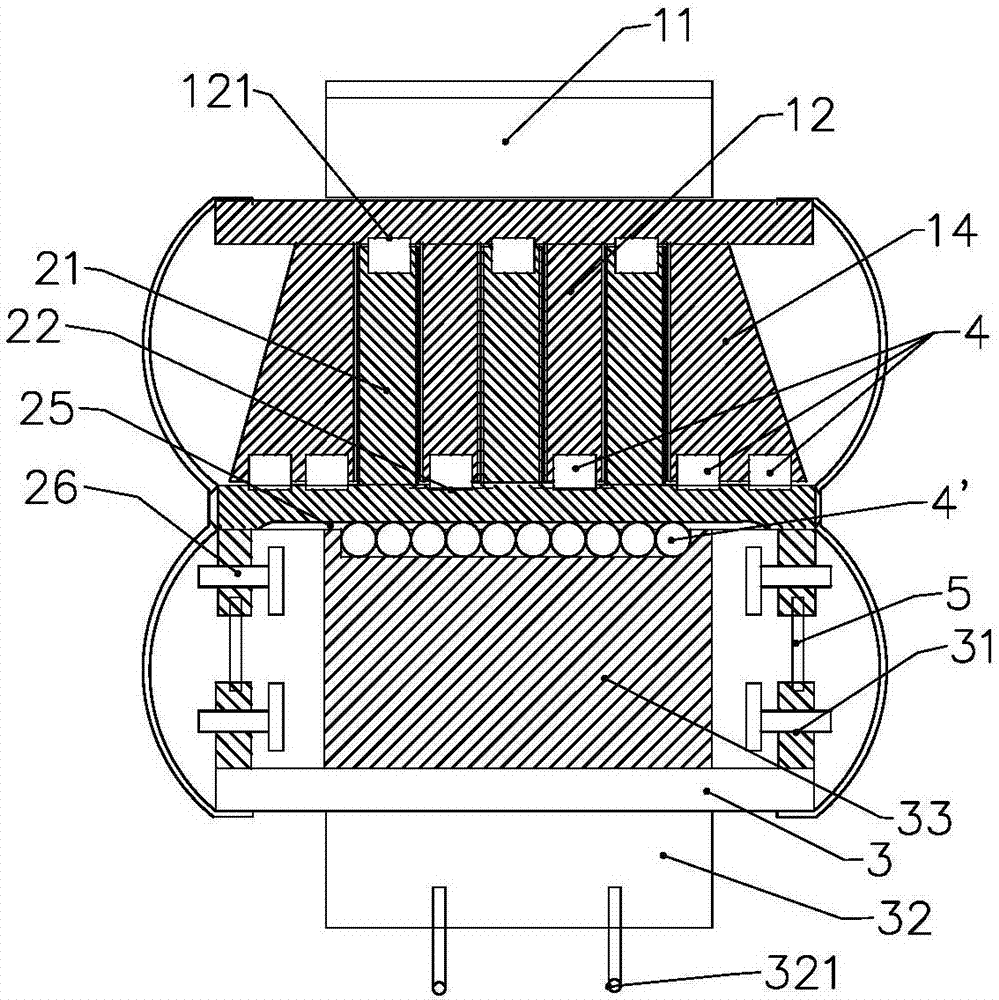

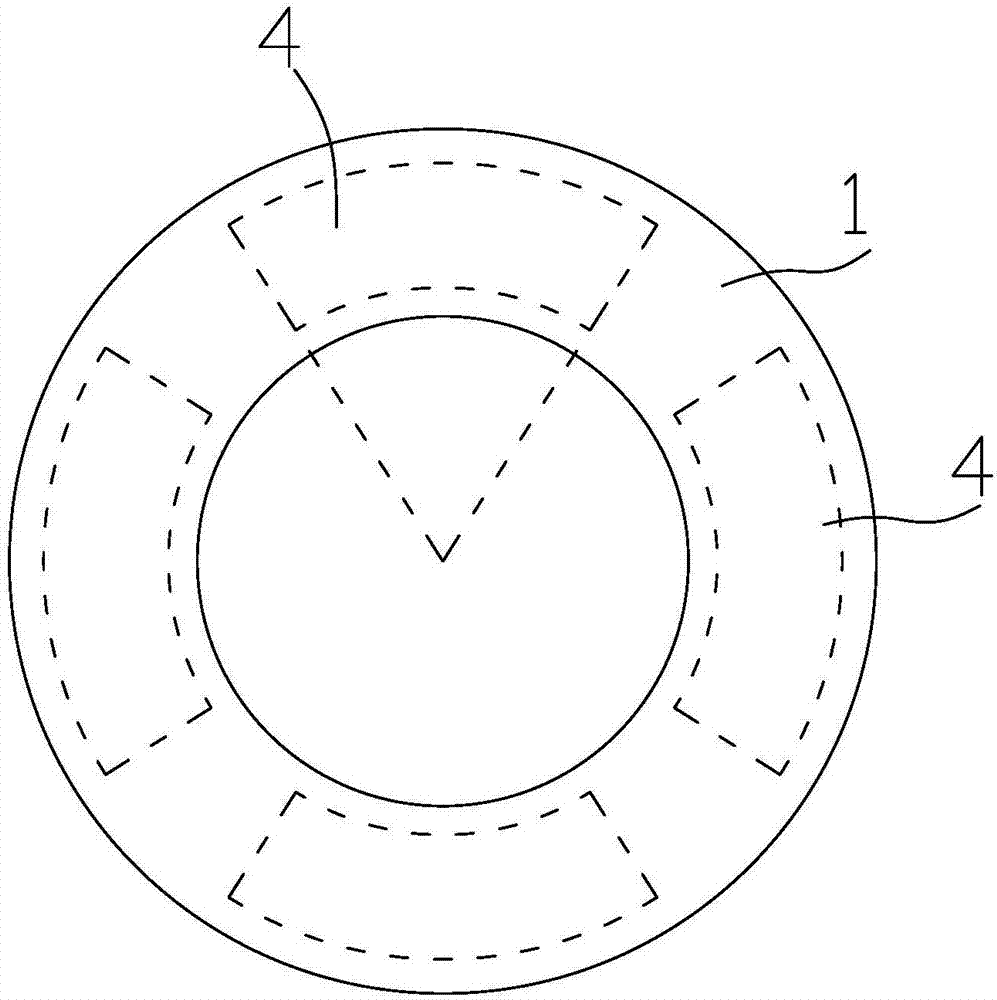

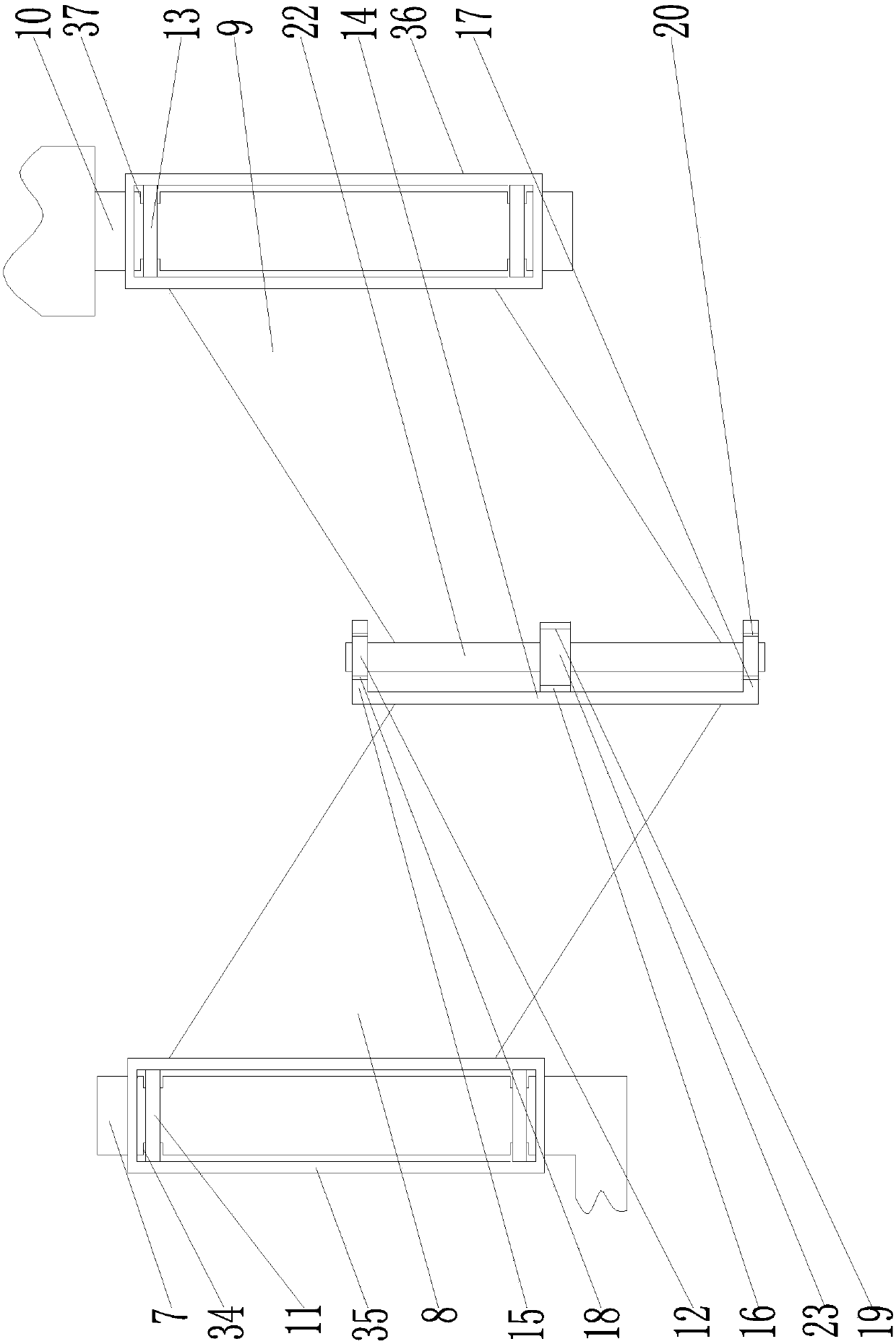

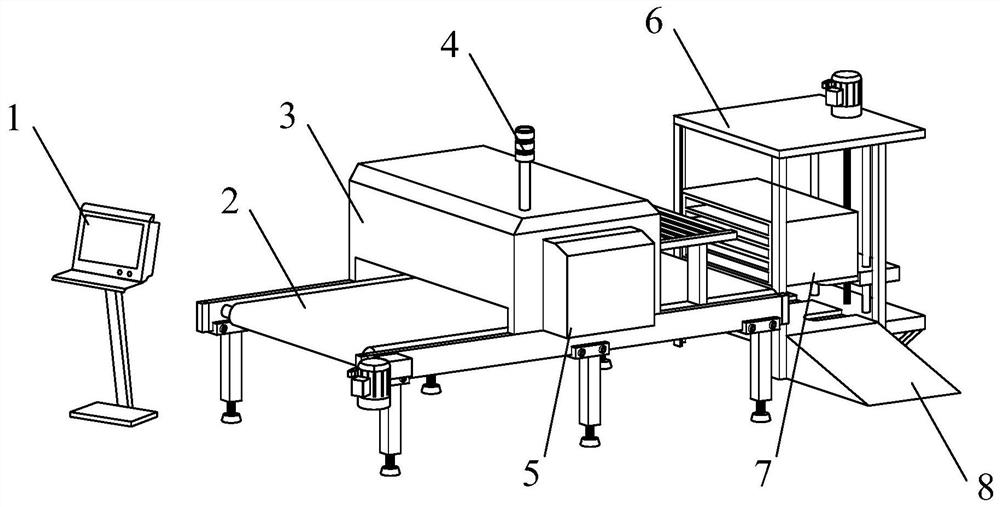

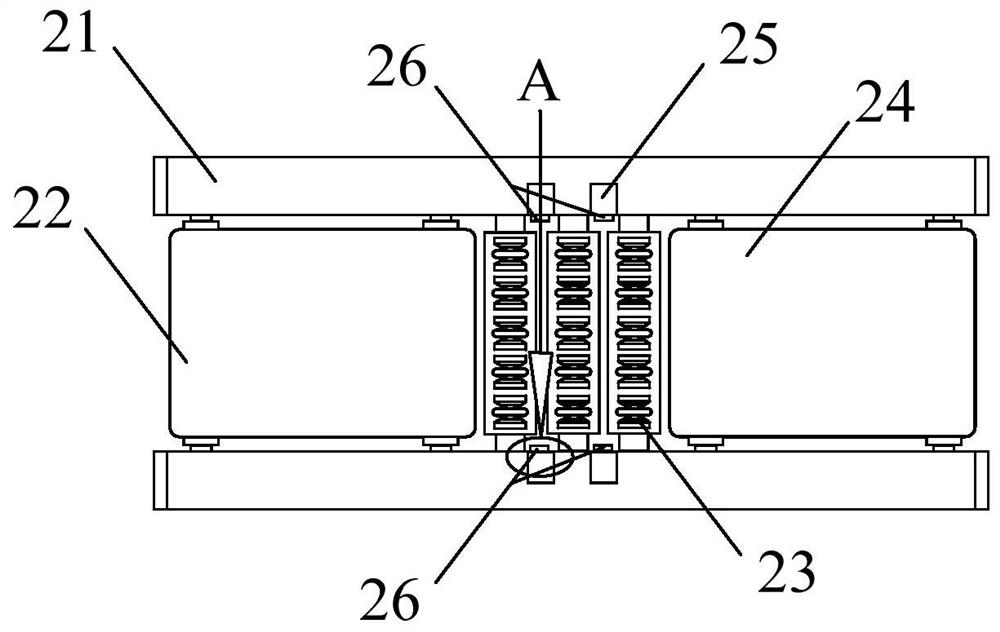

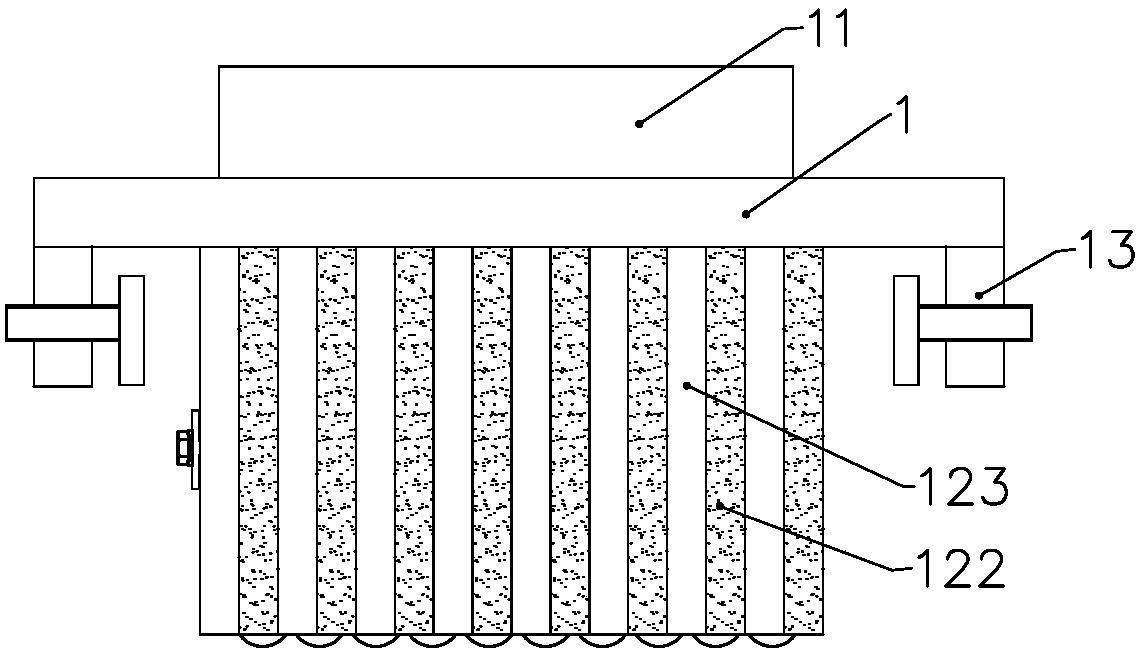

Conveying mechanism suitable for plates with different widths

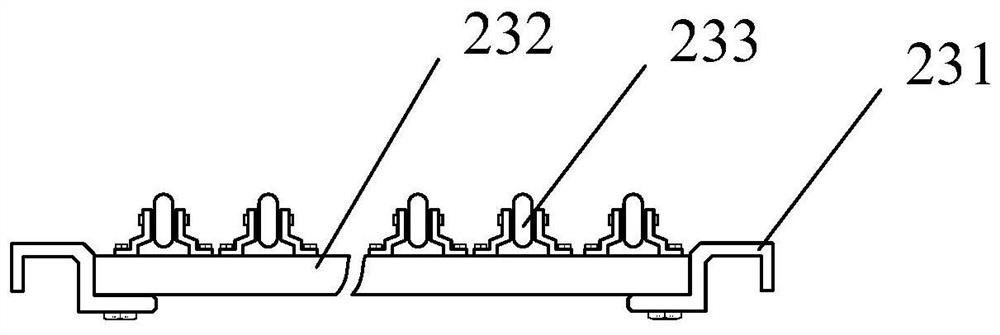

PendingCN107600931AFlexible distance adjustmentImprove adaptabilityMechanical conveyorsRoller-waysEngineeringIdler-wheel

The invention relates to the technical field of plate conveying equipment and particularly discloses a conveying mechanism suitable for plates with different widths. The conveying mechanism comprisesa bracket, a conveyer belt, a plurality of telescopic mechanisms and an auxiliary guide rail, wherein the auxiliary guide rail is arranged at the external part of a rack through the telescopic mechanisms; a plurality of idler wheels are arranged on the auxiliary guide rail; each of the telescopic mechanisms comprises a sleeve, a telescopic rod and a fixed rod; a plurality of circular arc-shaped limiting grooves are formed in the inner walls of the sleeve side by side; a plurality of guide grooves are formed in the end, close to the sleeve, of the telescopic rod; springs are arranged at the bottoms of the guide grooves; positioning balls are arranged at the free ends of the springs; a shrinking structure is arranged at the opening of each of the guide grooves; the diameter at the opening ofeach of the guide grooves is smaller than the external diameter of the corresponding positioning ball; the positioning ball protrudes out of the guide groove; the end, far away from the correspondingguide groove, of the telescopic rod is fixedly connected with the corresponding fixed rod; and the upper ends of the fixed rods are fixed at the bottom of the auxiliary guide rail. The conveying mechanism has the characteristics of being adjustable in width, higher in adaptation and higher in conveying efficiency.

Owner:浙江云峰莫干山家居用品有限公司

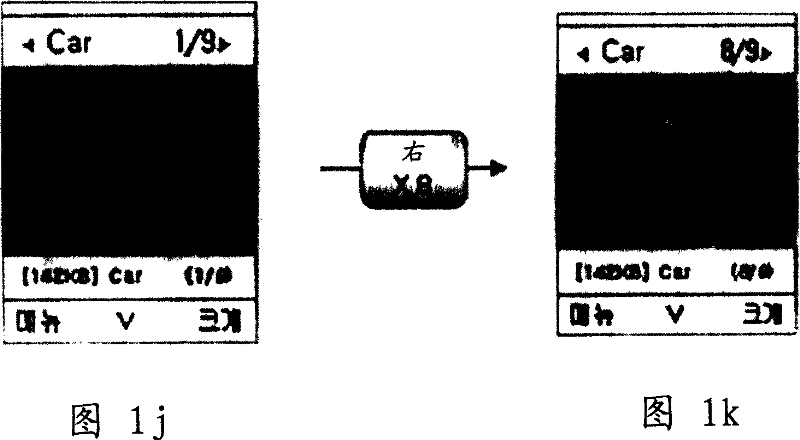

Touchpad-based input system and method for portable device

InactiveCN101038524AImprove handling conveniencePrecise positioningSubstation equipmentTransmissionTouchpadDisplay device

Owner:SAMSUNG ELECTRONICS CO LTD

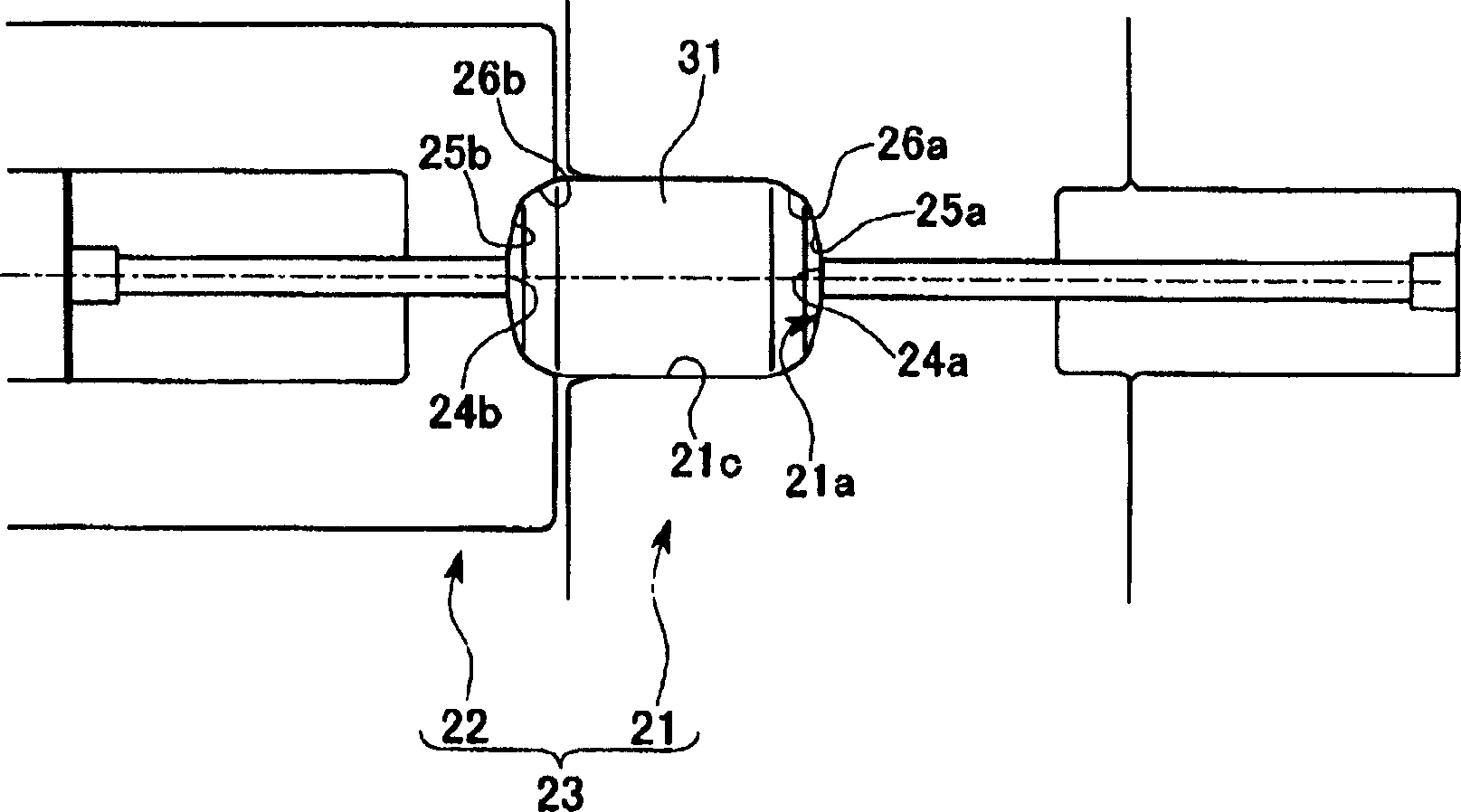

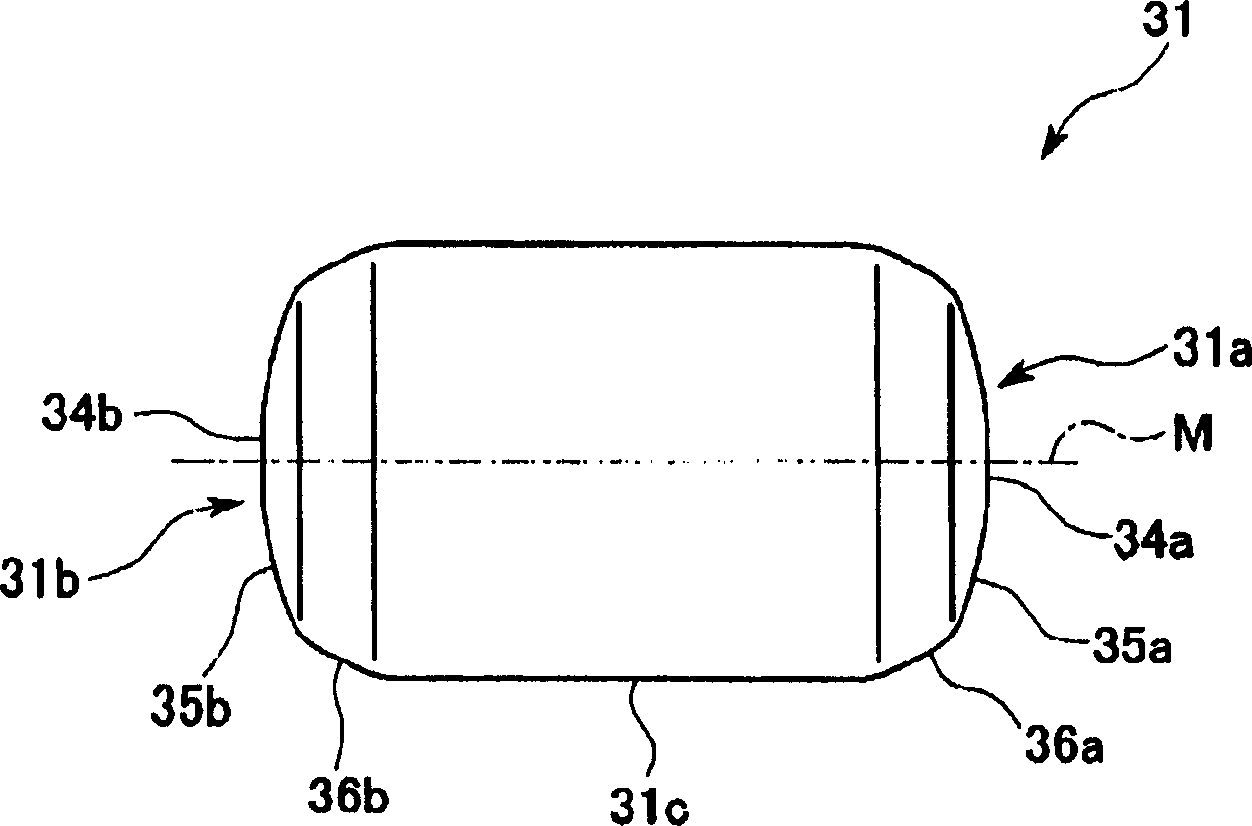

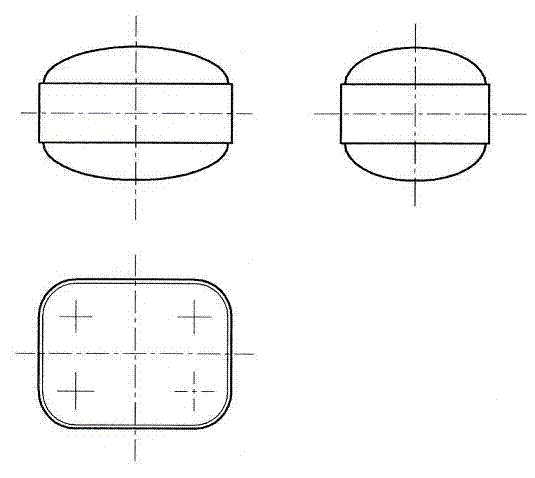

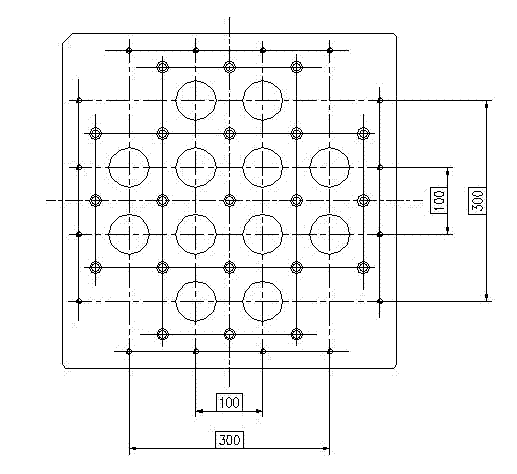

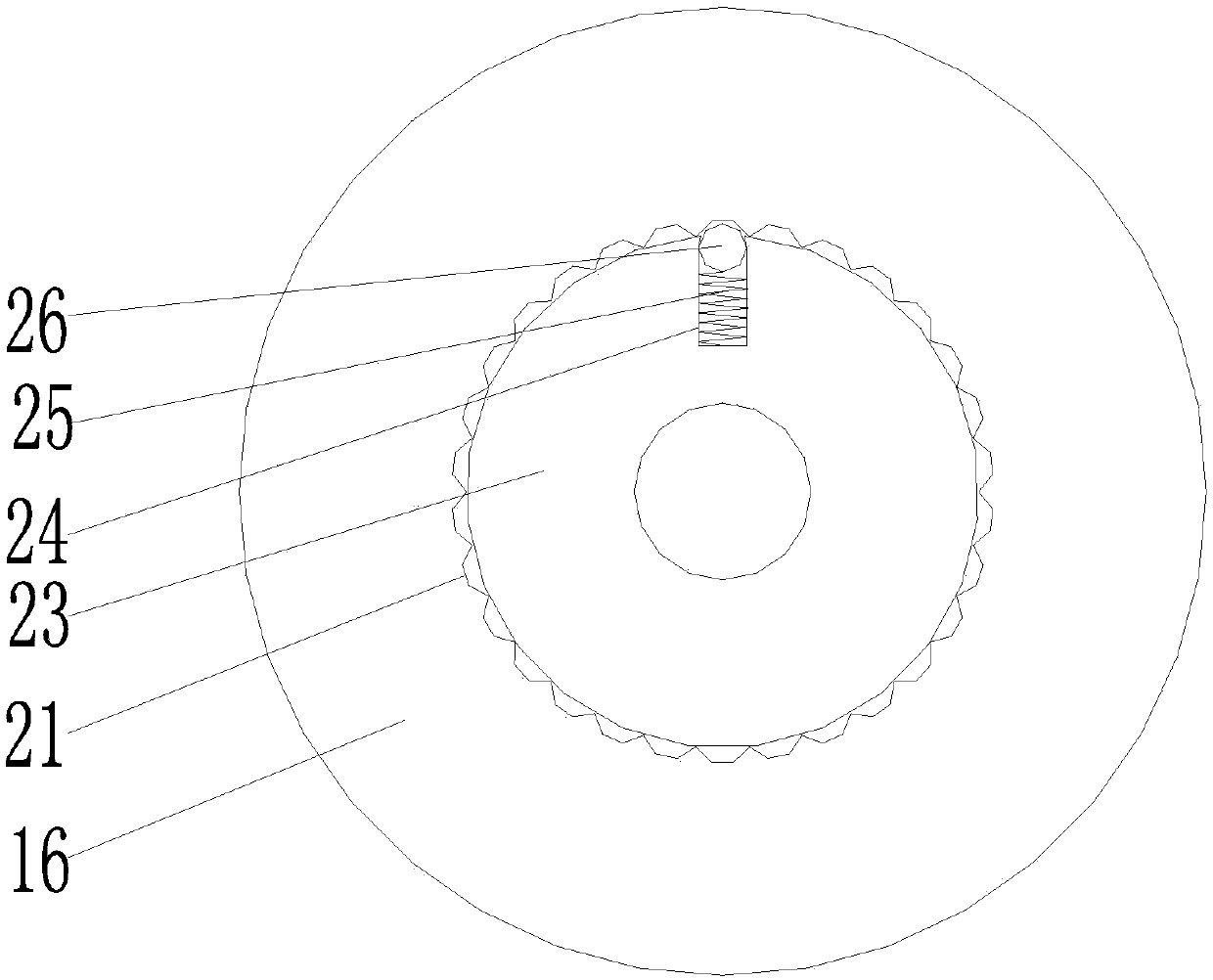

Production method of anode copper ball for electroplating and anode copper ball

ActiveCN1840261AGood sphericityEasy to take outPrinted circuit manufactureEngine componentsSpherical shapedMulti segment

The present invention provides a method for manufacturing anode copper balls for electroplating. When forming an anode copper ball for electroplating by forging without oil supply, it can be stably manufactured, and the flat surface existing on the surface can be reduced as much as possible to manufacture rolling balls. Anode copper balls with good electroplating properties. As the manufacturing method of anode copper balls for electroplating, utilize the mold (23) that is made up of multiple sets of dies (21) and punching machine (22), carry out cold multi-stage forging to form balls from copper rods, wherein Connected to the inner wall surface of the die (21), the copper bar is forged in its axial direction, and the first intermediate material (31) is formed into a spherical shape through the first forging process. In the forging process, the outer circumference of the end surface is crushed As the first intermediate material (31) of the tapered surface.

Owner:MITSUBISHI MATERIALS CORP

Hydrogen-permeable alloy, and hydrogen-permeable film and its production method

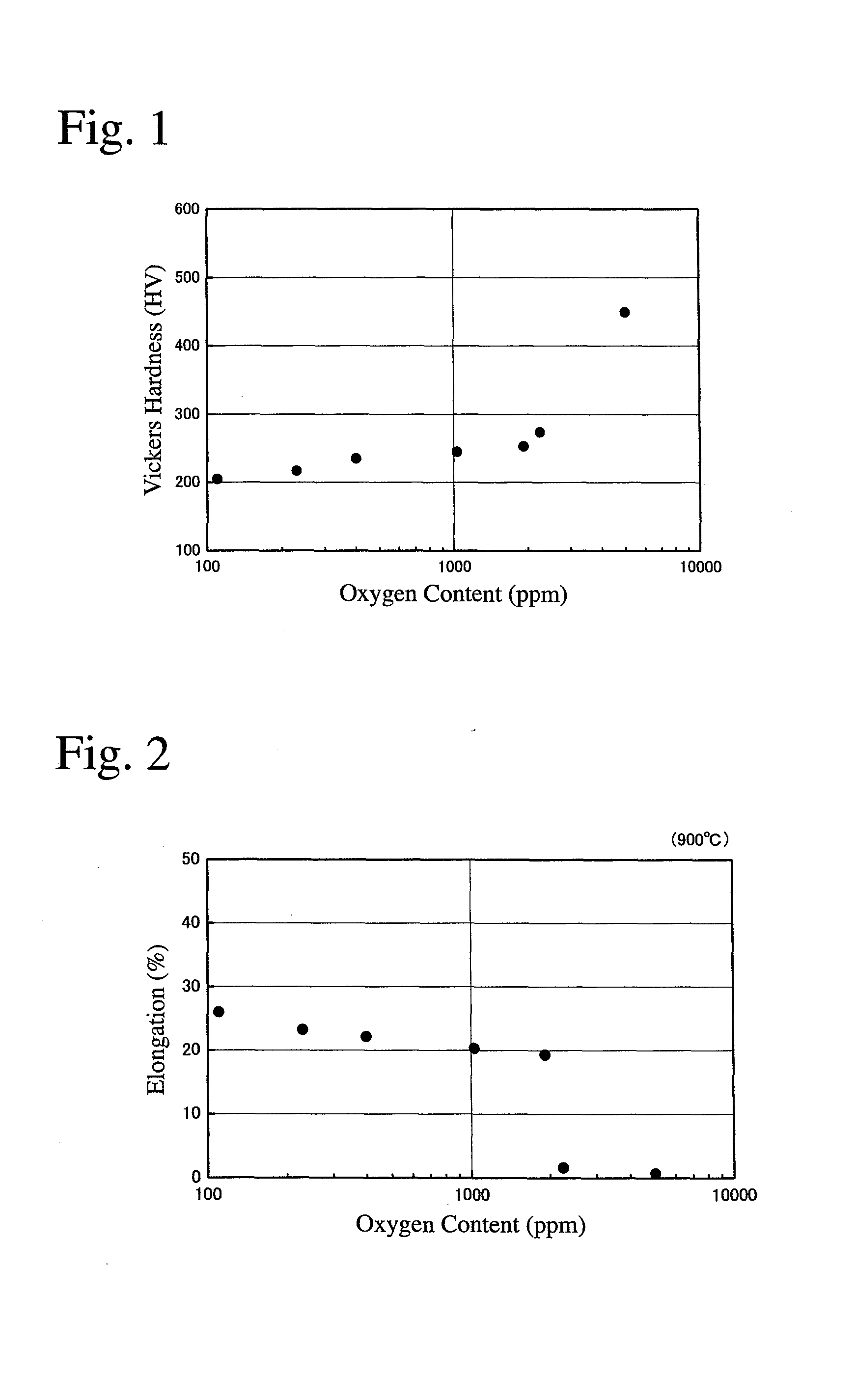

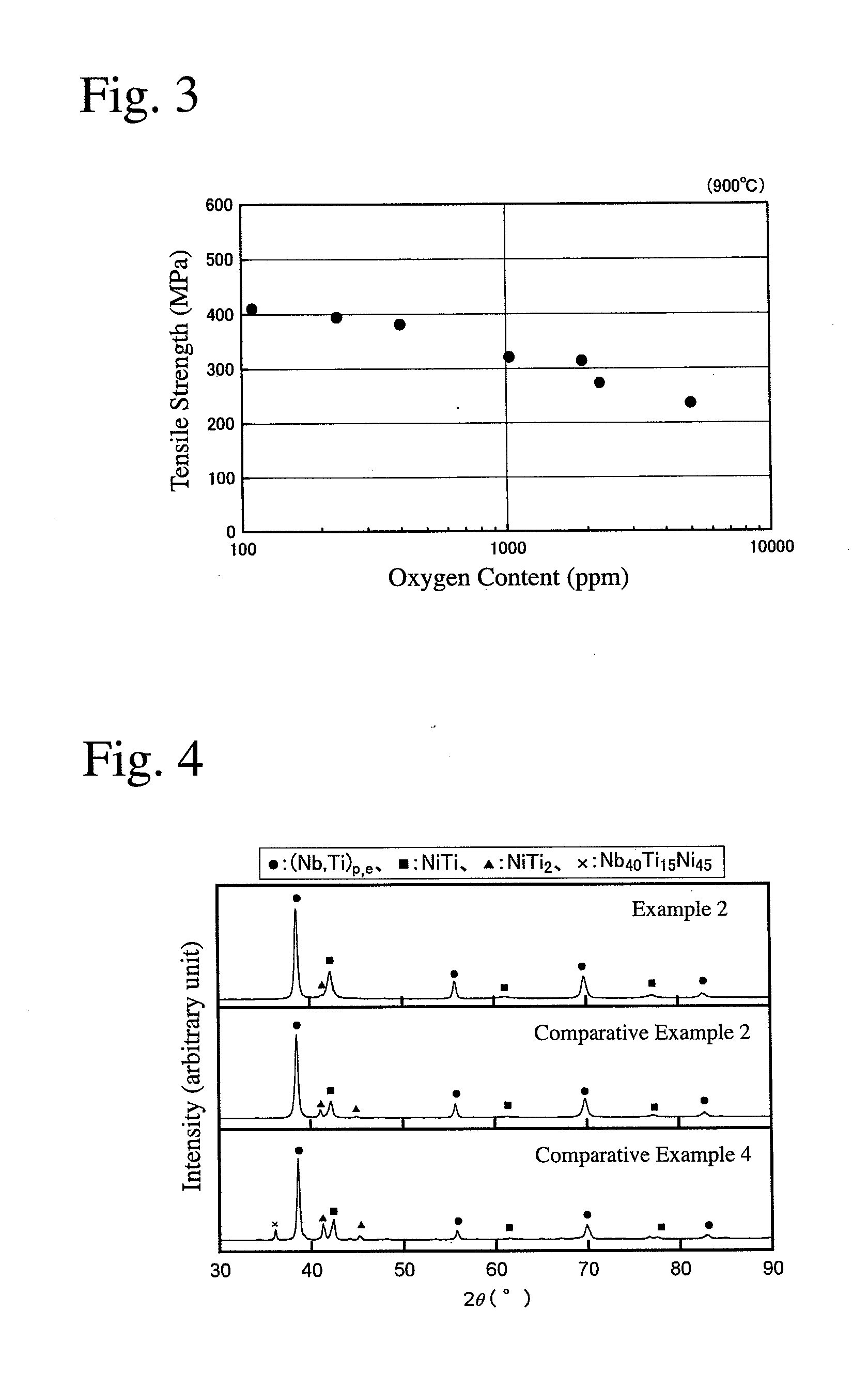

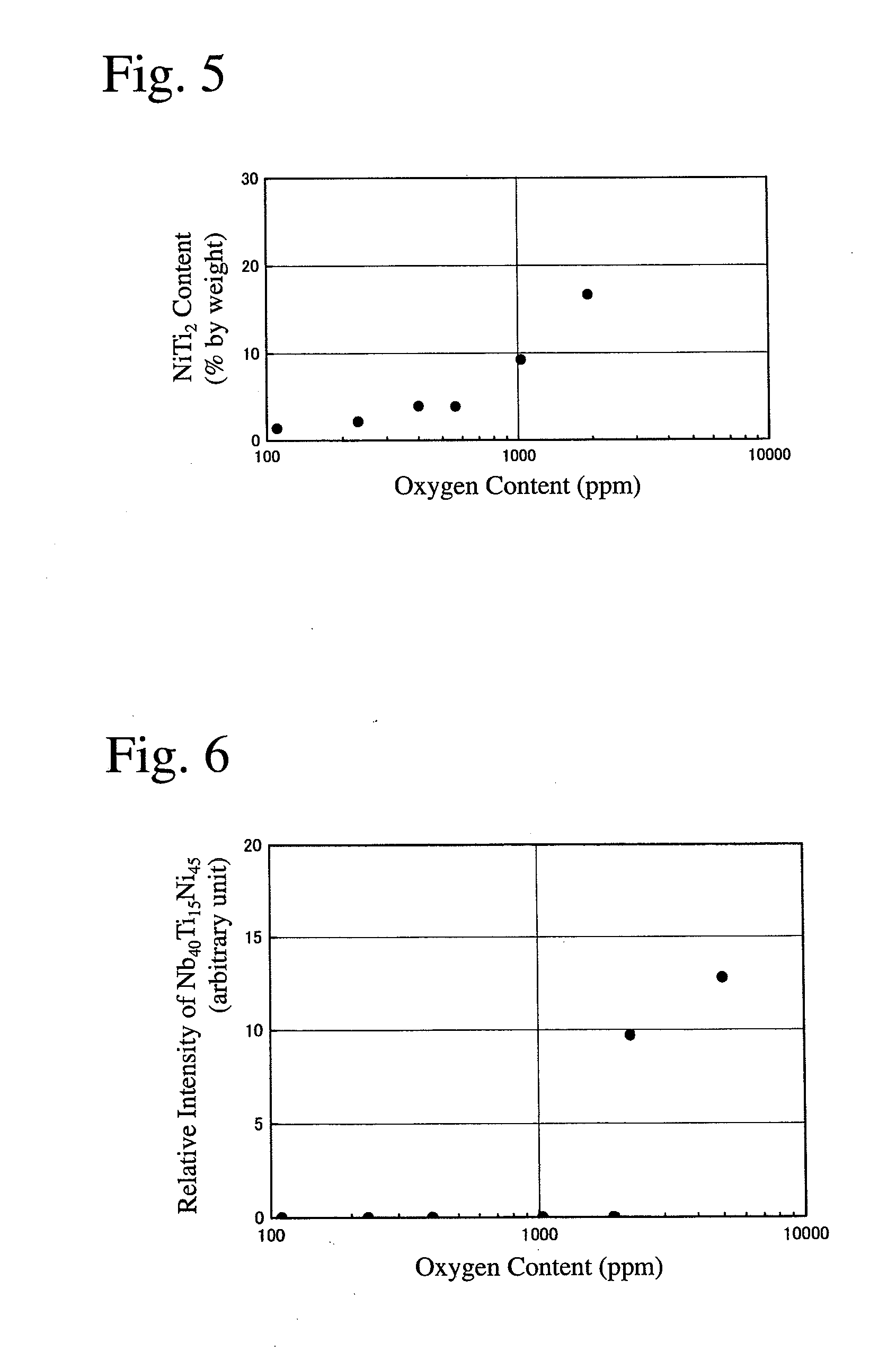

InactiveUS20100092333A1Low oxygenImprove permeabilitySemi-permeable membranesMembranesThin membraneAlloy

A hydrogen-permeable Nb—Ti—Ni alloy having a composition represented by Nb100-x-yTixNiy, wherein 10≦x≦60, and 10≦y≦50 by atomic %, with an oxygen content of 1000 ppm or less in an as-cast state, which comprises (a) a hydrogen-permeable primary phase containing 70 atomic % or more of Nb and 10 atomic % or less of Ni, and (b) a eutectic phase having a particle phase comprising Nb and Ti as main components with a small Ni content and having an average particle size of about 5 μm or less, which is dispersed in a matrix phase comprising 60 atomic % or more in total of Ni and Ti and having hydrogen embrittlement resistance, the alloy having a structure substantially free from an intermetallic compound phase.

Owner:HITACHI METALS LTD

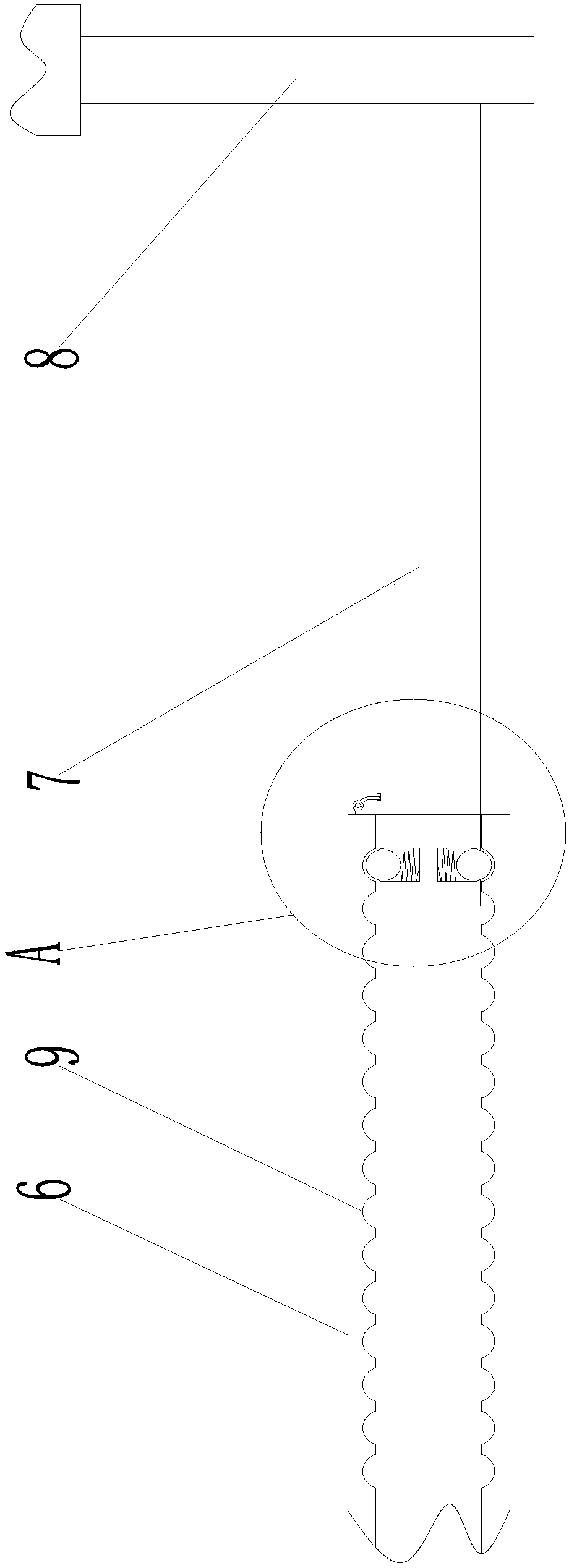

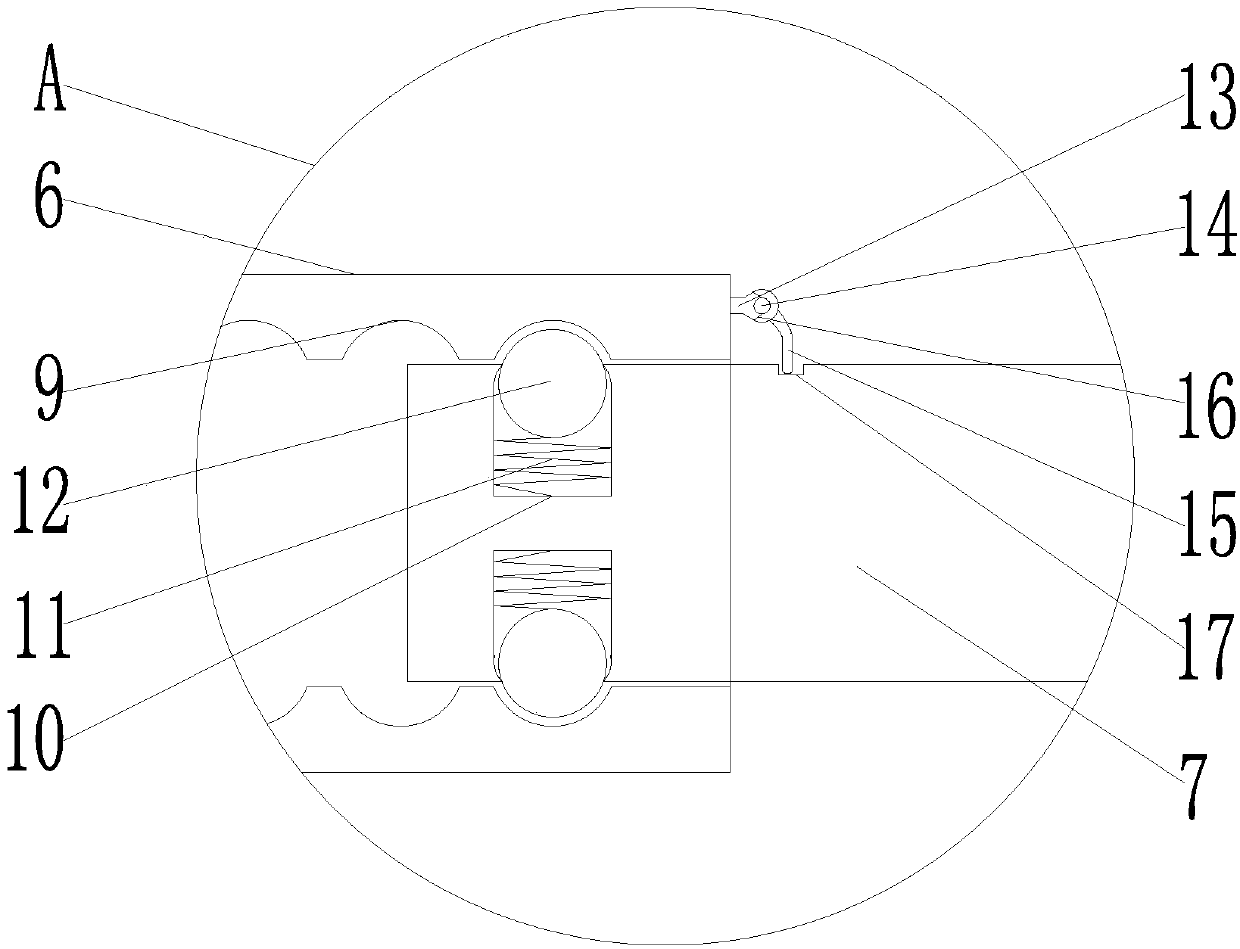

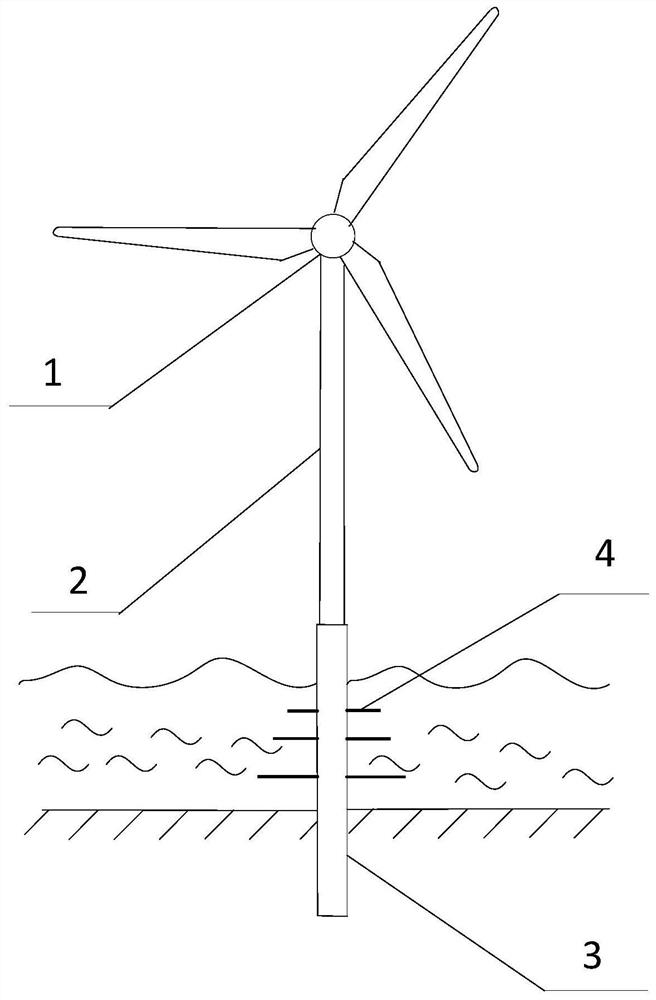

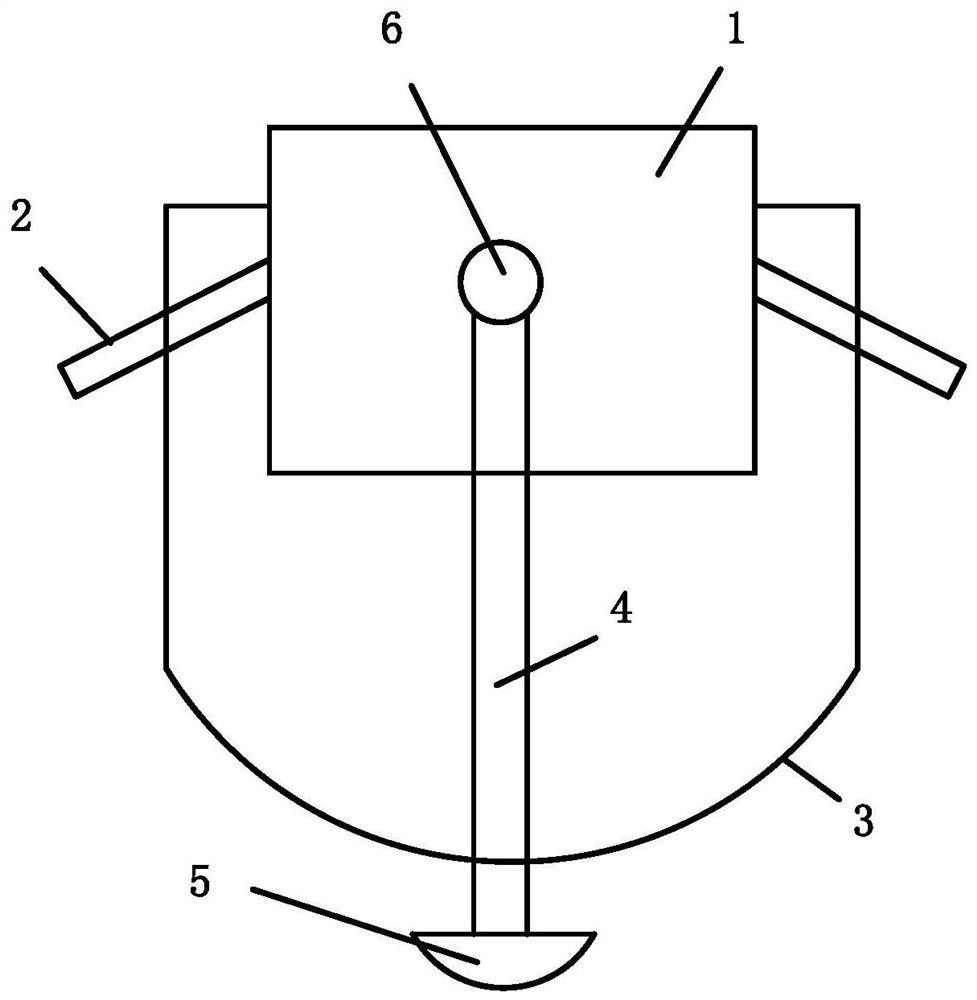

Anti-scouring offshore wind power single pile foundation device

PendingCN113186967ABlocking of diggingImprove stabilityClimate change adaptationFoundation engineeringWater trapEngineering

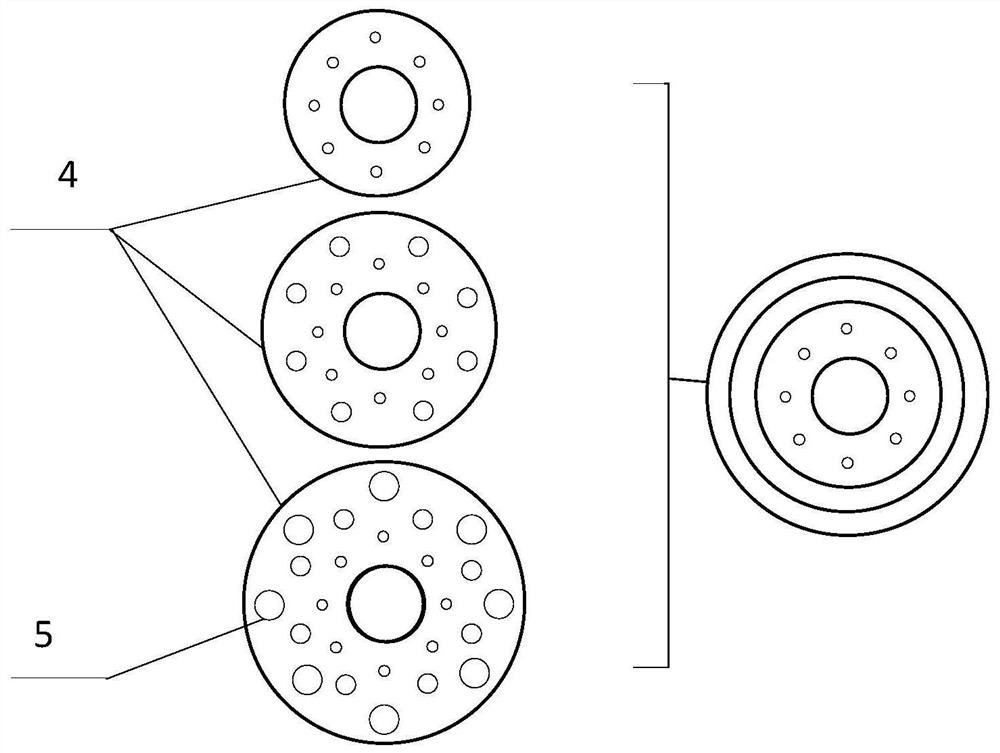

The invention discloses an anti-scouring offshore wind power single pile foundation device. The anti-scouring offshore wind power single pile foundation device is characterized in that protection disc devices are fixed on a pile foundation; the lower end of the pile foundation is fixed at the bottom of a seabed; the protection disc devices are fixed on the pile foundation, and the protection disc devices are located below the sea level; a wind power main machine and a wind power tower drum are sequentially installed on the single-pile foundation; a protection layer is formed on the outer side of the pile foundation 3 through the protection disc devices, impact is formed on the periphery of the pile foundation when seawater washes the pile foundation, and under the blocking effect of the protection disc devices, formation and transmission of a diving vortex structure, a horseshoe-shaped vortex structure and a wake vortex structure are effectively limited; the winding and digging effect of diving vortexes on the seabed surface can be effectively blocked, wherein a plurality of protection disc devices are mounted on the pile foundation and are horizontally arranged; a multi-layer protection layer structure is formed by the plurality of horizontally arranged protection disc devices, the stability of the protection disc devices is improved, and meanwhile, the winding and digging effect of blocking diving vortexes on the seabed surface can be improved by the plurality of horizontally arranged protection disc devices.

Owner:HUANENG POWER INT ENERGY DEV CO LTD +2

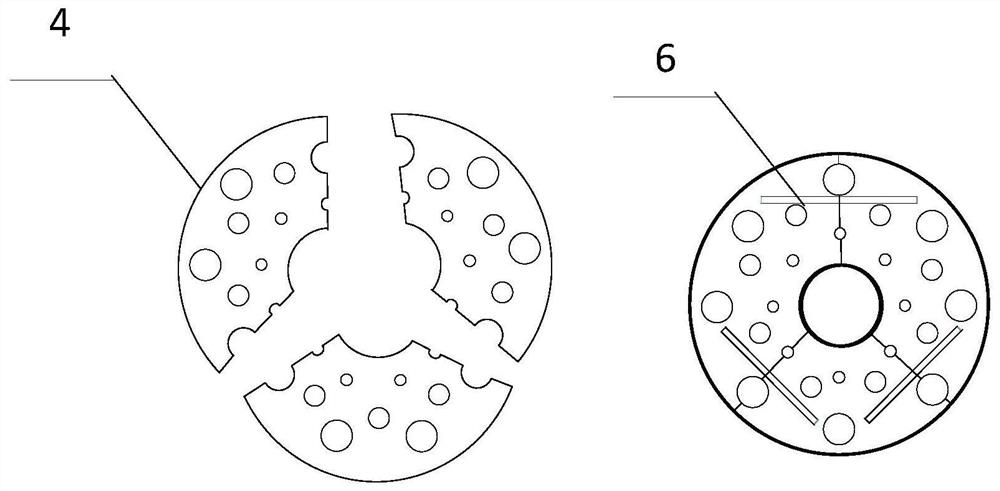

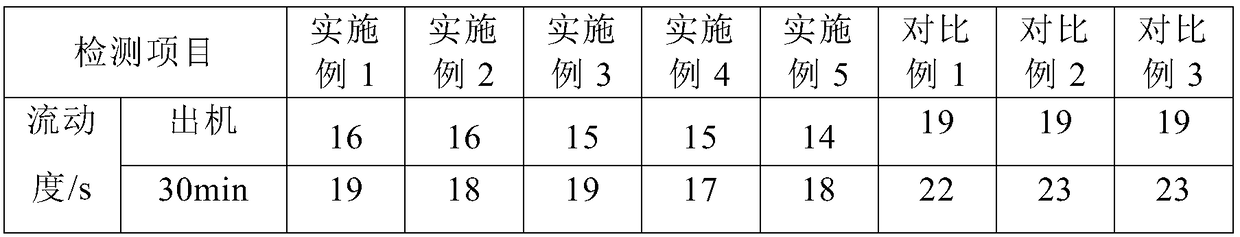

Ultrafine inorganic grouting material for tunnel inverted arches, and preparation method thereof

ActiveCN109020419AGuaranteed mechanical propertiesImprove early strengthWater reducerMaterials science

The invention discloses an ultrafine inorganic grouting material for tunnel inverted arches. The grouting material comprises, by mass, 75-90% of an ultrafine cementing material, 5-20% of a mineral filler, 2.5-7.5% of a composite expansion agent, 0.04-0.08% of a fluid volume stabilizer, 0.5-1.5% of a film forming modifier, 0.4-0.8% of a water reducer, 0.02-0.05% of a defoamer, 0.1-0.4% of a dispersant, 0.05-0.1% of an anti-seepage water repellent and 1-5% of a nano-reinforcing component. Above components are uniformly mixed, water is added according to a water-cement ratio of 0.25-0.30, and stirring is performed to obtain the grouting material which can be used for grouting reinforcement portions and defect parts of the tunnel inverted arches. The inorganic grouting material obtained in theinvention is suitable for repairing and stabilizing defects and dangerous rock bodies of tunnel inverted arches at 5-35 DEG C, has the advantages of high fluidity, high bonding strength, no shrinkage, good impermeability and good durability, and is suitable for being promoted and applied.

Owner:HUBEI UNIV

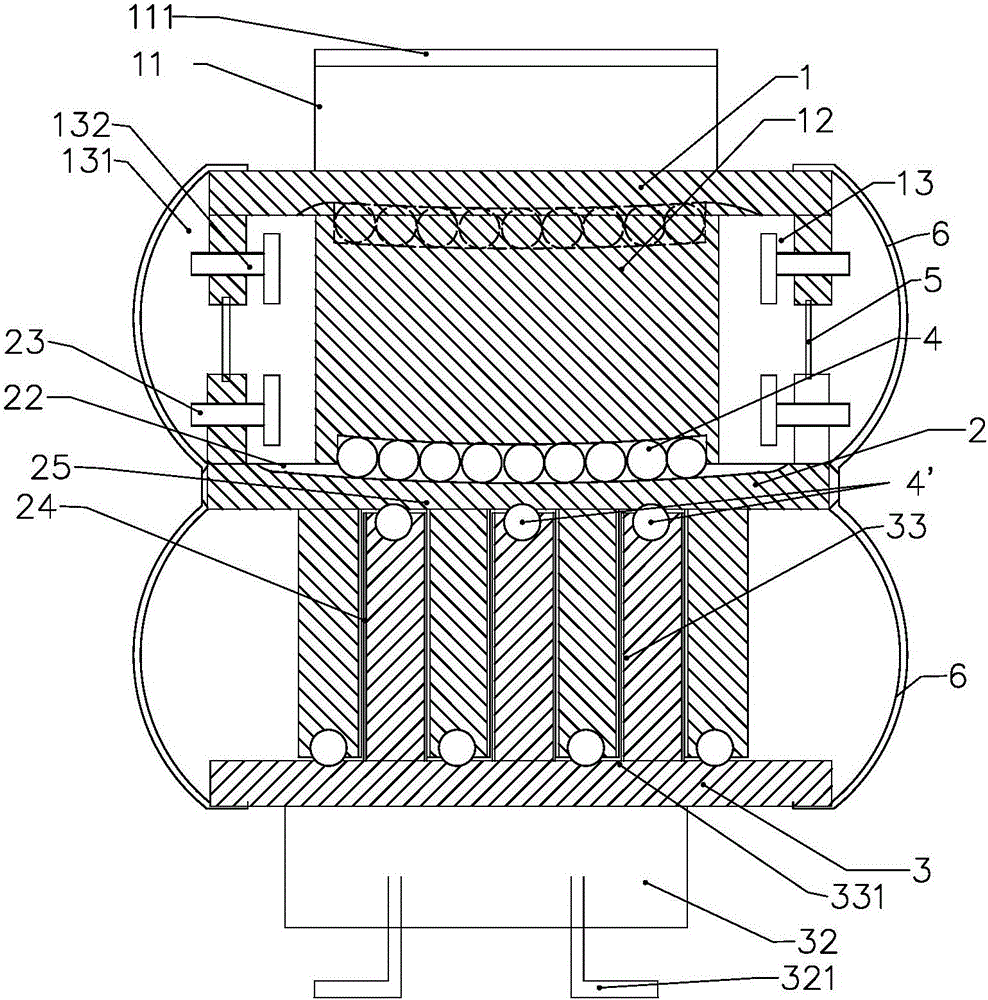

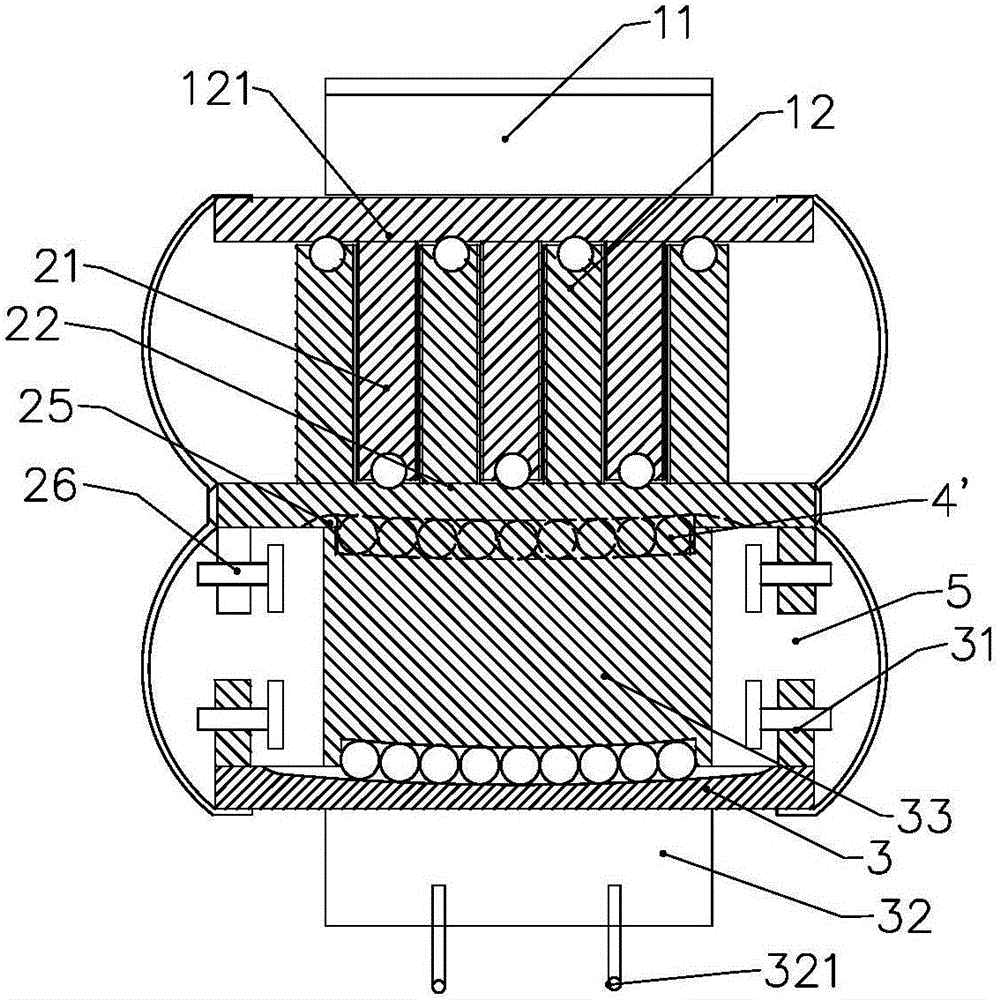

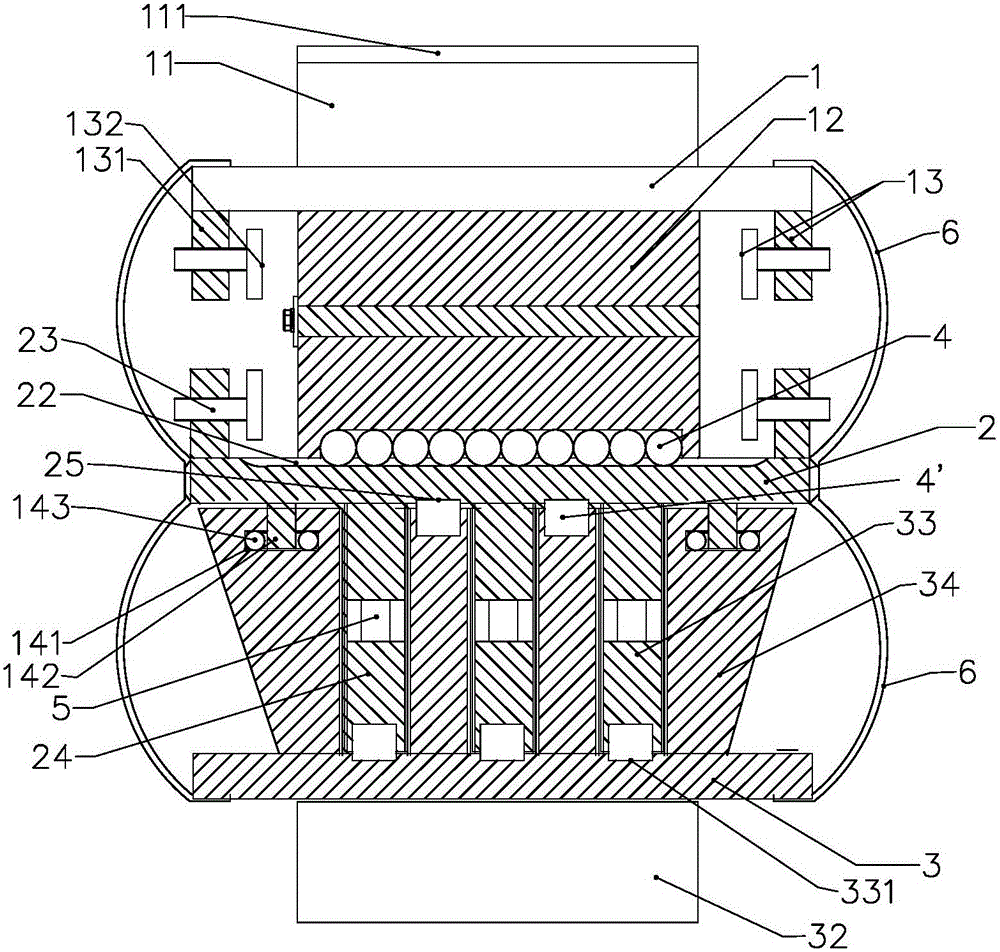

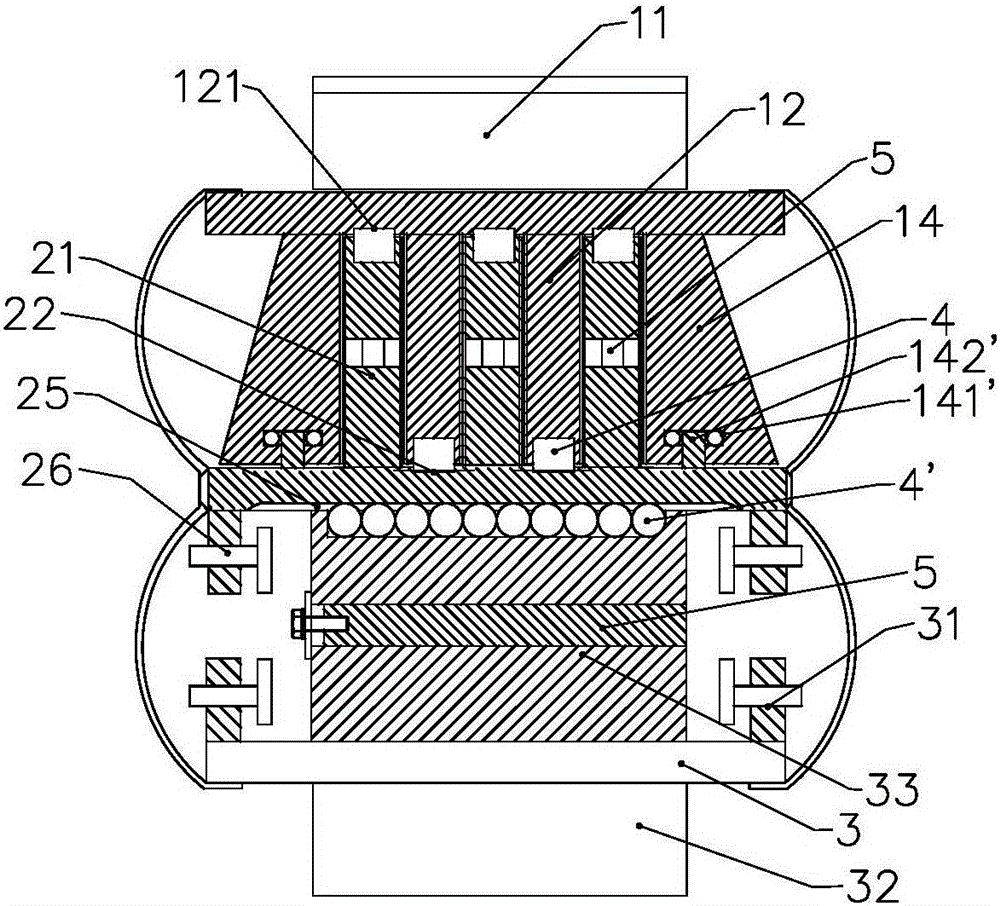

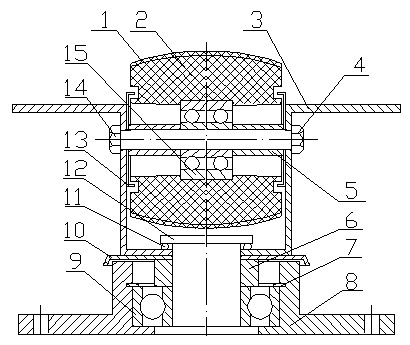

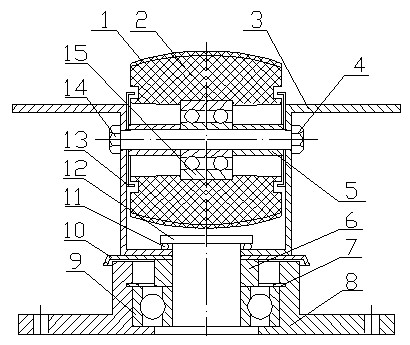

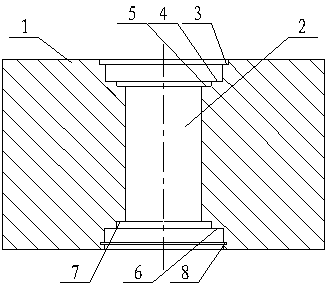

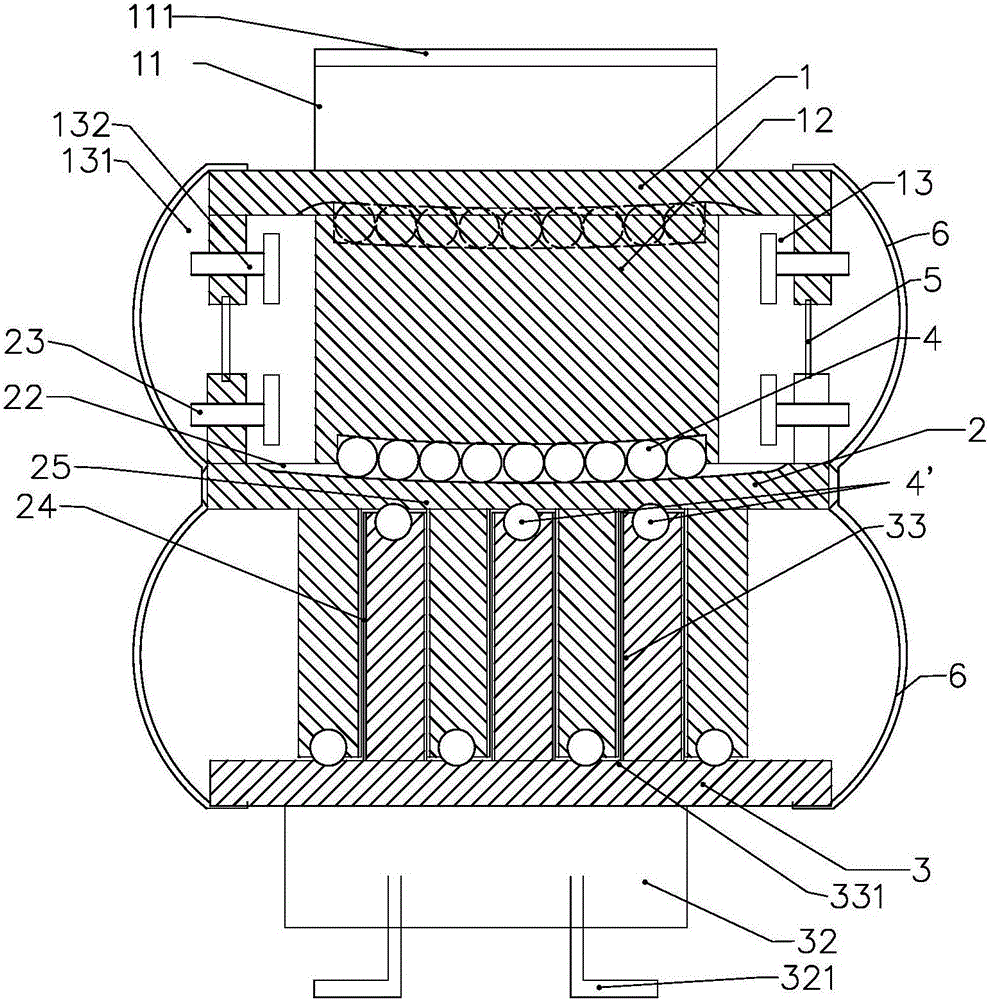

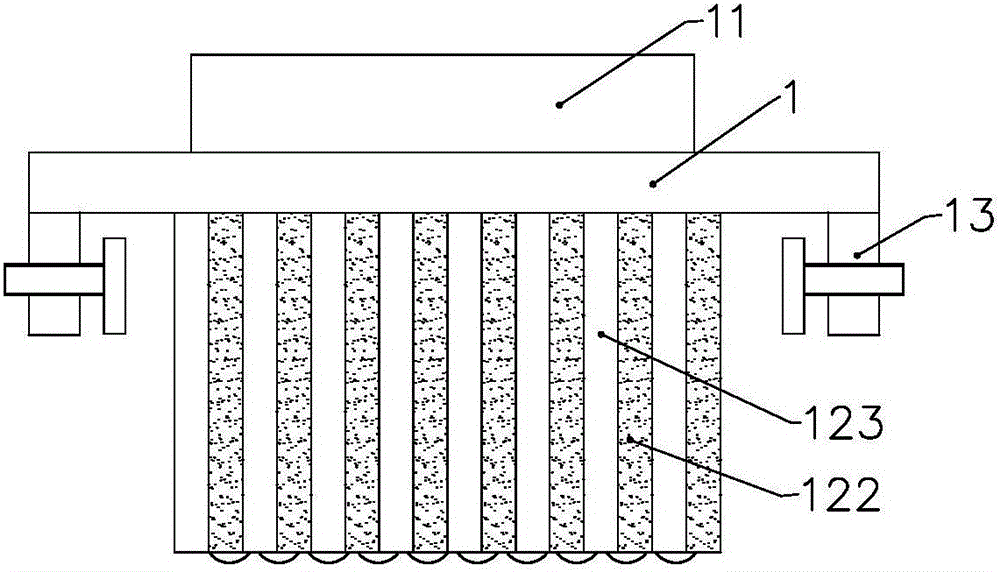

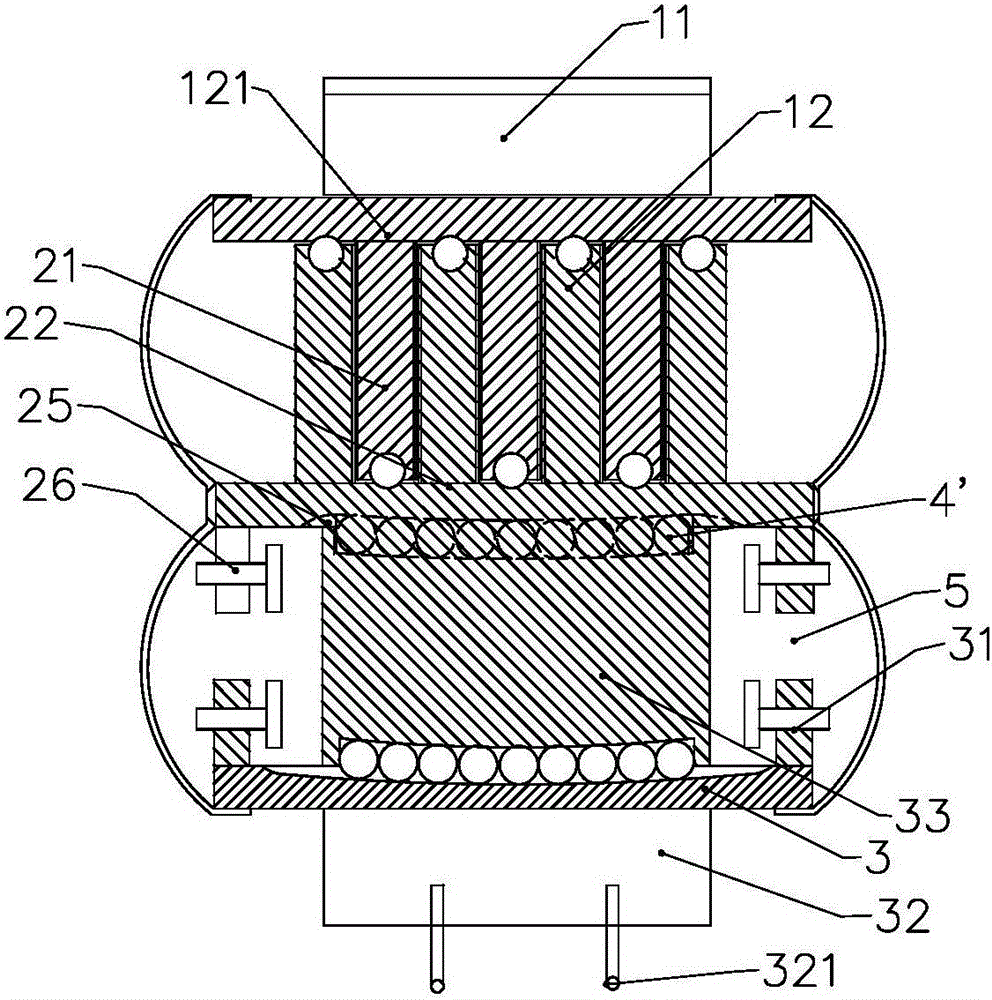

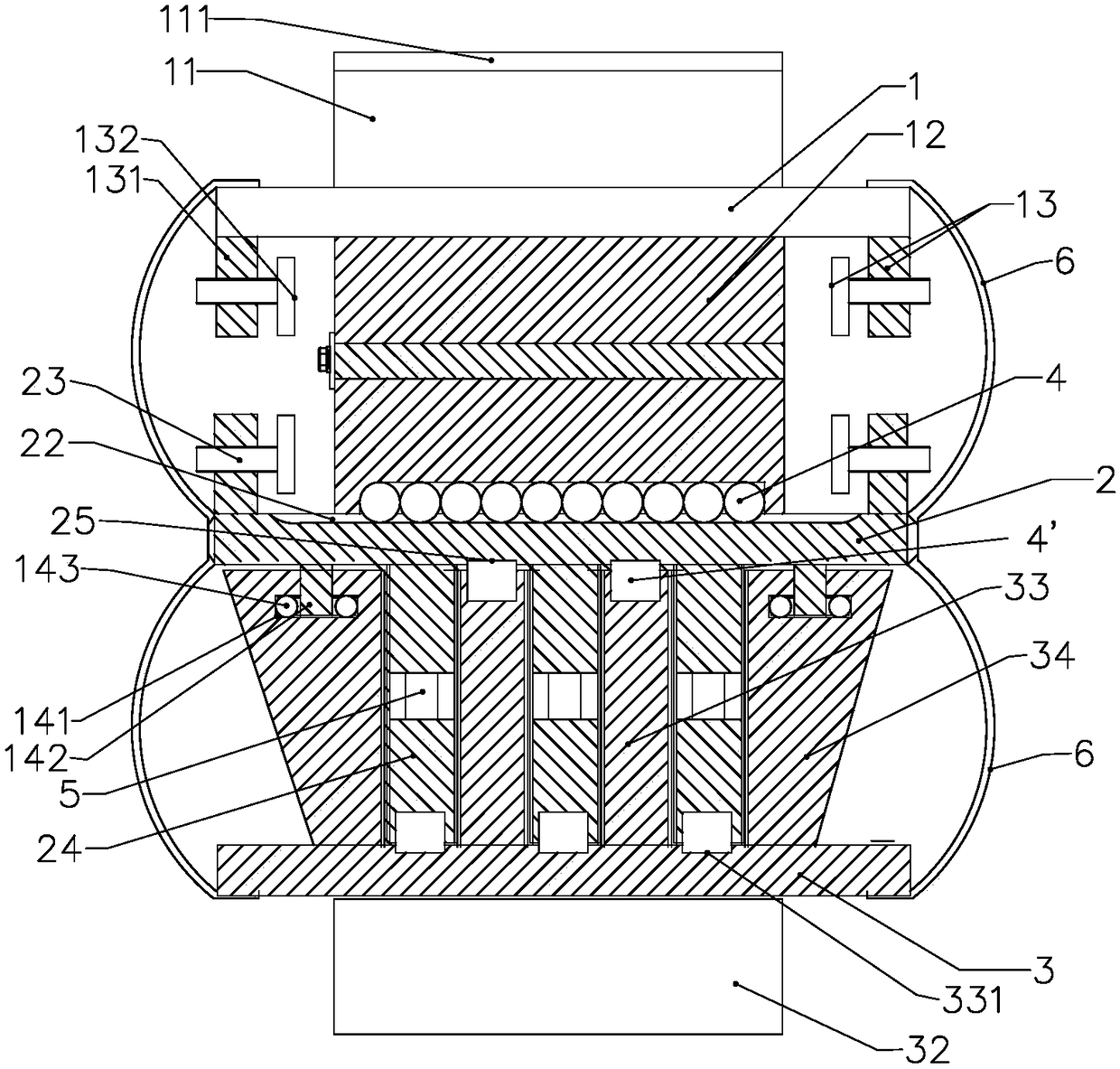

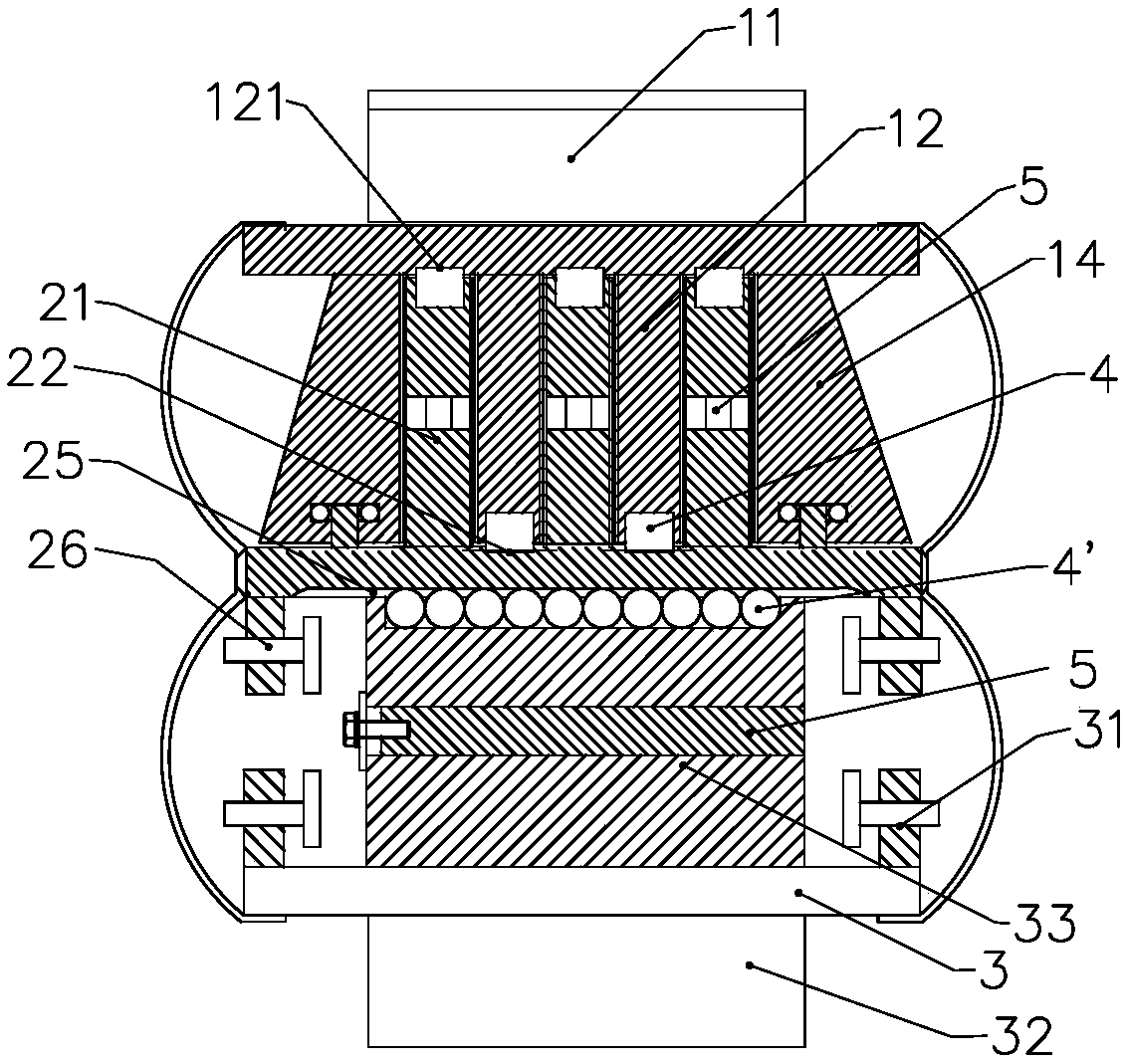

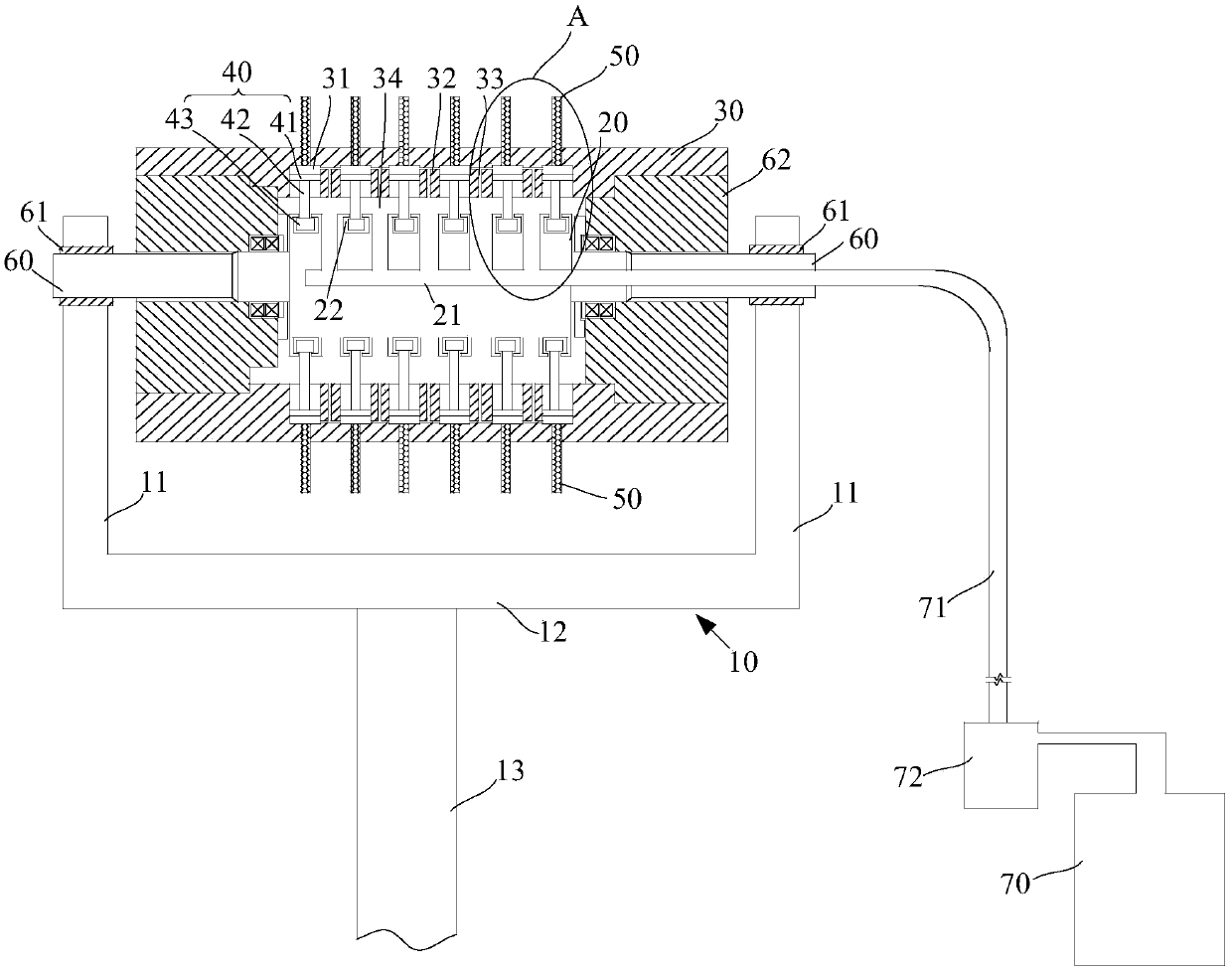

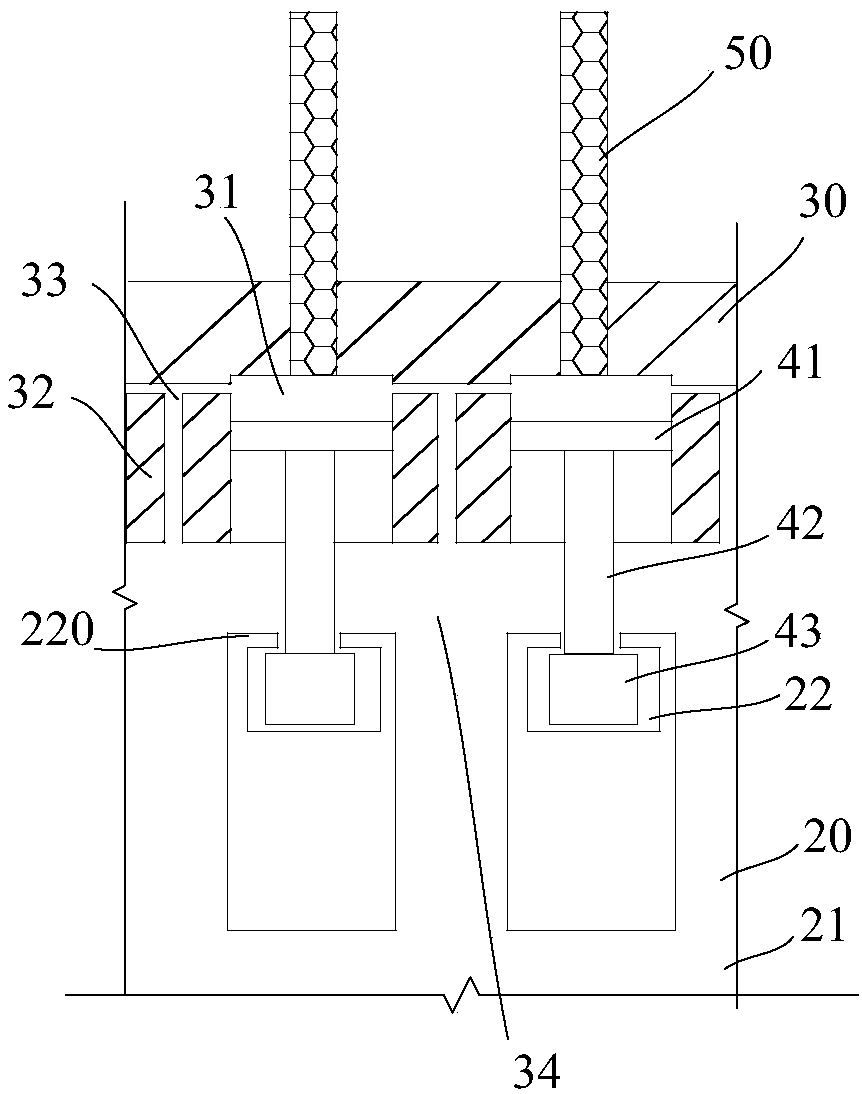

Engineering three-dimensional aligning shock-isolation and anti-seismic support

InactiveCN106013917AHigh sensitivityImprove scrolling effectBridge structural detailsProtective buildings/sheltersDynamic balanceEngineering

Owner:石彦龙 +5

Method for preparing artificial stone needle

PendingCN108751930ARegular shapeImprove scrolling effectLight therapyCeramic materials productionHuman bodyFar infrared

The invention provides a method for preparing an artificial stone needle. The method comprises the following steps: an ore treatment step, a clay treatment step, a porcelain clay preparation step, a porcelain glaze preparation step, a molding step, and a sintering step. Stoneware prepared from the artificial stone needle of the invention has regular shape, round and smooth appearance, excellent rolling property and contact sense, high strength and wear resistance, emits far infrared rays of greater than 13-14 [mu]m matched with bands required for living organisms, has good thermal effect and resonance effect, can promote blood circulation and metabolism of a human body, and can achieve excellent effects by combining with stone needle therapy of Chinese medicine.

Owner:方厉远

A high-efficiency energy-saving low-carbon manganese sphere production process

InactiveCN102266941AImprove scrolling effectGood density consistencyMaximum dimensionRolling resistance

A production process of high-efficiency and energy-saving low-manganese balls is as follows: (1) Take low-carbon electrolytic metal manganese sheet and roll it into powder; (2) Add inorganic binder without S, P, C and other elements in the bowl mixer Stir quickly and evenly; ⑶Put it into a 12-station forming mold for molding within a limited time, and the shape of the green compact is double-ball table cylinder or square chewing gum (maximum size≯33mm); ⑷Roast and dry the green compact within the effective time; ⑸ Vacuum sintering and drying the compact within the effective time; (6) Sintering the compact through an inclined sieve moisture-proof packaging within the effective time to obtain a content of C<0.03%, S<0.03%, Si<0.5%, Mn≥97.5%, crushing destructive power ≮1.5kN low-carbon manganese balls. The production process is short, clear, efficient, and environmentally friendly. The shape of the product is regular, the rolling property is good, the density / composition is uniform, the strength is moderate, and it is easy to implement precise addition.

Owner:吴庆定

Anti-capsizing support of bridge

InactiveCN106087717AHigh sensitivityStrong blessingBridge structural detailsScrew threadFriction force

The invention discloses an anti-capsizing support of a bridge. The anti-capsizing support of the bridge comprises a first plate, a second plate and a third plate, wherein the first plate, the second plate and the third plate are arranged in parallel from top to bottom. Clamping grooves are formed in the two sides of a second insertion plate vertically. Each clamping groove communicates with a channel through a square hole between the clamping groove and the channel. A movable brake pad is placed in each clamping groove. A tie piece is arranged in the channel. Wedges are arranged on the two sides of the tie piece at intervals and face the same direction, and each wedge makes contact with the movable brake pad in the corresponding position. A threaded hole is formed in the end of the tie piece, and a tension bolt is installed in the threaded hole for tensioning connection. The anti-capsizing support of a bridge is of a pure mechanical structure, and long-term maintenance-free operation can be achieved; and in addition, main friction force happens to friction plates between the insertion plates, the automobile brake pads are used as the friction plates and are free of maintenance in the whole life, and the friction force of the brake pads can be adjusted conveniently through the tension bolt.

Owner:孙新迪 +11

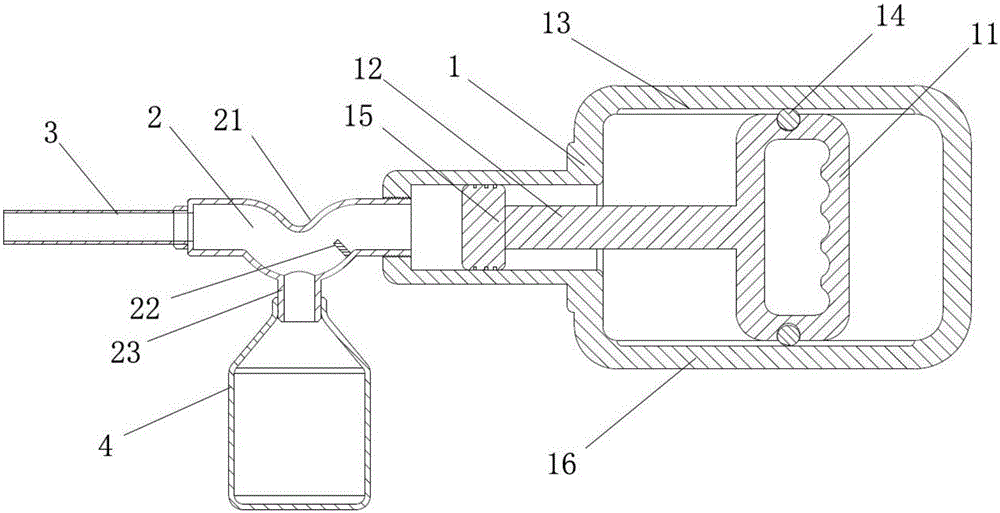

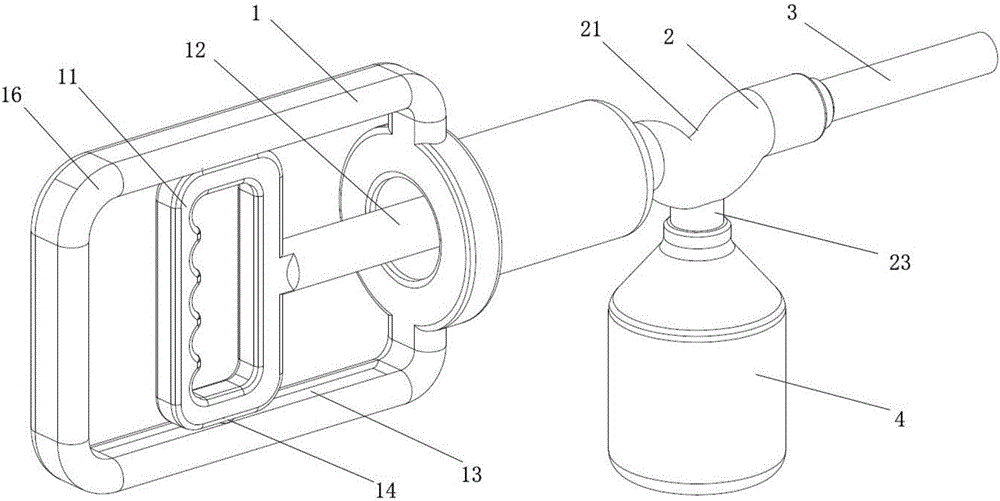

Manual sputum aspirator

InactiveCN106344973ACreate pollutionEasy to disassembleMedical devicesIntravenous devicesHand heldEngineering

The invention discloses a manual sputum aspirator, comprising a piston assembly, a transition tube and a sputum suction tube, wherein one end of the transition tube is connected with the sputum suction tube while the other end thereof is connected with the piston assembly in sealing; the piston assembly comprises a piston shell, a hand-held handle, a piston and a connecting rod; the hand-held handle is connected with the piston through the connecting rod; a pulley element is respectively arranged in two contact planes of the hand-held handle and the piston shell; the middle part of the transition tube is downward sunken into a 'V-shaped' tube, a sputum-obstructing plate is arranged in an oblique plane of the inner tube surface of the 'V-shaped' tube, and the inner tube surface is adjacent to one end of the piston; the bottom of the 'V-shaped' tube is connected with a branched tube on which a sputum-collecting bottle is connected in sealing. The manual sputum aspirator is simple in structural design and convenient to operate; various parts are easy to disassemble and assemble and convenient to clean and disinfect, and thus the manual sputum aspirator has a good sputum collecting effect.

Owner:宁芳

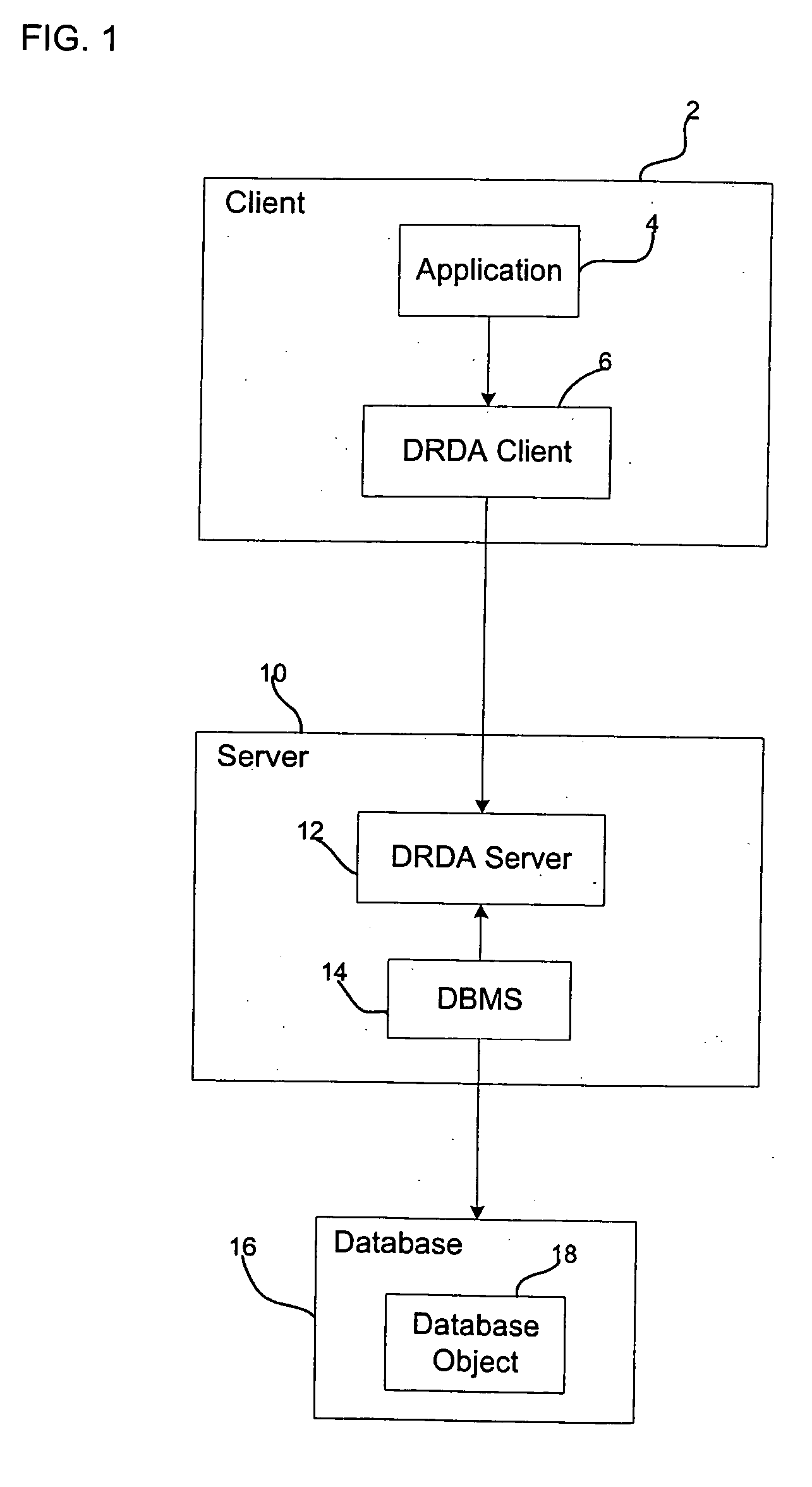

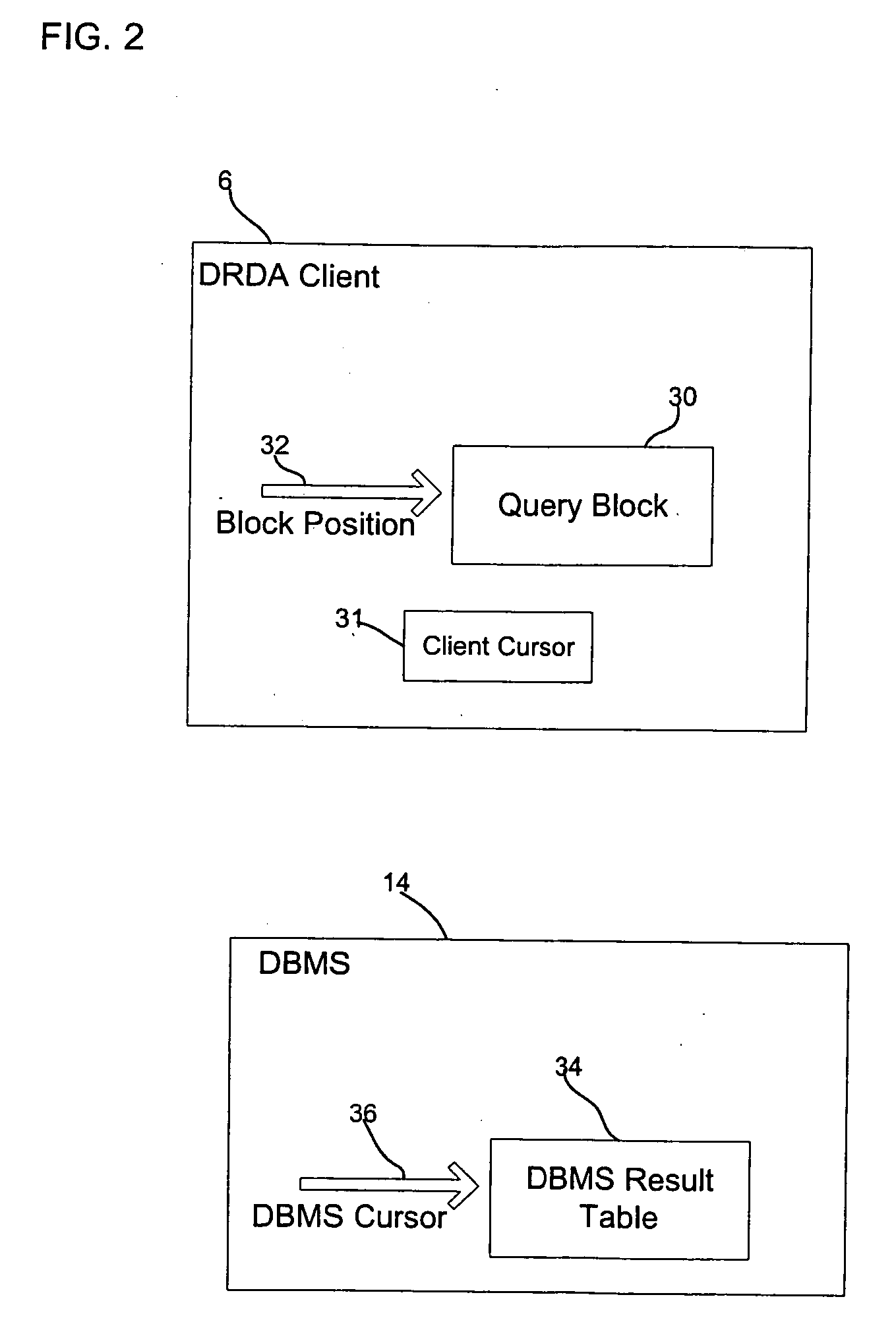

Method, system, and program for implementing scrollable cursors in a distributed database system

InactiveUS20050228823A1Reduce in quantityImprove performanceData processing applicationsDigital data processing detailsClient-sideDistributed database

Owner:INT BUSINESS MASCH CORP

Steel-plastic universal wheel

The invention relates to a steel-plastic universal wheel which has the characteristics of flexible rotation and easy walking and can not be damaged under the condition of large carrying capacity. The steel-plastic universal wheel comprises a universal wheel, wherein the tire of the universal wheel comprises a plastic tire core and a metal rim covered on the wheel surface of the plastic tire core;a bearing is embedded in a wheel center of the plastic tire core and positioned in a wheel carrier through a bearing shaft; and the wheel carrier is matched with a wheel seat through a pin shaft and the bearing and enables the wheel seat to rotate for 360 degrees. The invention has the following advantages: (1) the steel-plastic universal wheel has large carrying capacity, and can easily move androtate with the carried goods; (2) the steel-plastic universal wheel has simple structure, compact assembly and good tightness; (3) the wheel carrier adopts bearing rotation and has stable and flexible rotation; and (4) the steel-plastic universal wheel has long service life, and is especially suitable for use in places which is easy to impact by external force, and has large load capacity and very bad work environment.

Owner:杭州红箭电器制造有限公司

Modification technology of 3D printing-molded powder material

InactiveCN105541247AShorten hardening timeTo meet the needs of rapid hardeningSulfateForming processes

The invention belongs to the technical field of powder material modification and discloses a modification technology of a 3D printing-molded powder material. Through calcium sulfate powder modification, calcium sulfate powder hardening time is greatly reduced and fast hardening demands in 3D printing molding are satisfied. Through use of a dispersant, relative independence of powder is kept so that good rolling effects are obtained and the problem of printing head blocking caused by easy dust rising in printing is solved and thus a mold printing precision is improved.

Owner:HEILONGJIANG HEIKE TECH CO LTD

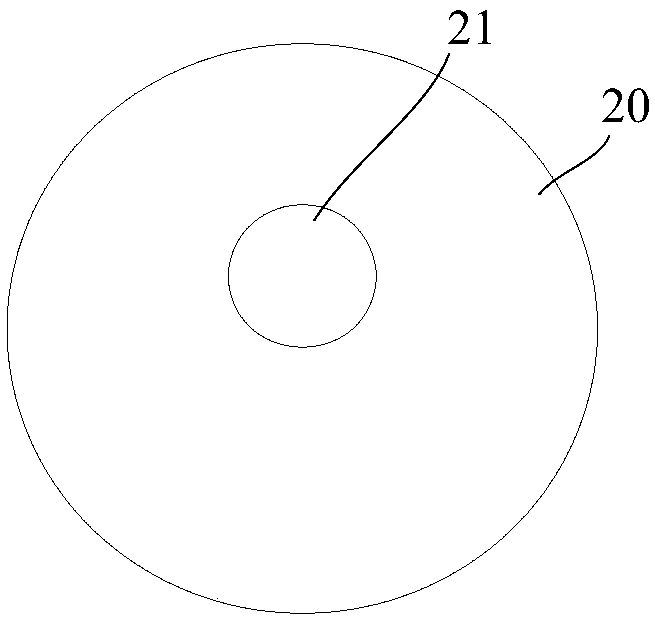

Microfiltration machine riding wheel and manufacturing method thereof

InactiveCN103127831AImprove stabilityImprove scrolling effectUltrafiltrationEngineeringMicrofiltration

The invention discloses a microfiltration machine riding wheel which comprises a body, wherein an axle hole is formed in the center of the body; a first circular truncated cone, a second circular truncated cone and a third circular truncated cone are sequentially formed from inside to outside on the body of one side surface of the axial hole; the diameters of the first circular truncated cone, the second circular truncated cone and the third circular truncated cone decreases gradually sequentially; the width of the second circular truncated cone is greater than the widths of the first circular truncated cone and the second circular truncated cone; a fourth circular truncated cone and a fifth circular truncated cone are sequentially formed from outside to inside on the body of the other side surface of the axial hole; and an annular groove is formed in the middle of the fourth circular truncated cone. Through the designed microfiltration machine riding wheel, the stability of the riding wheel is improved, and a riding wheel body can be fixed well through a plurality of circular truncated cone surfaces.

Owner:李国章

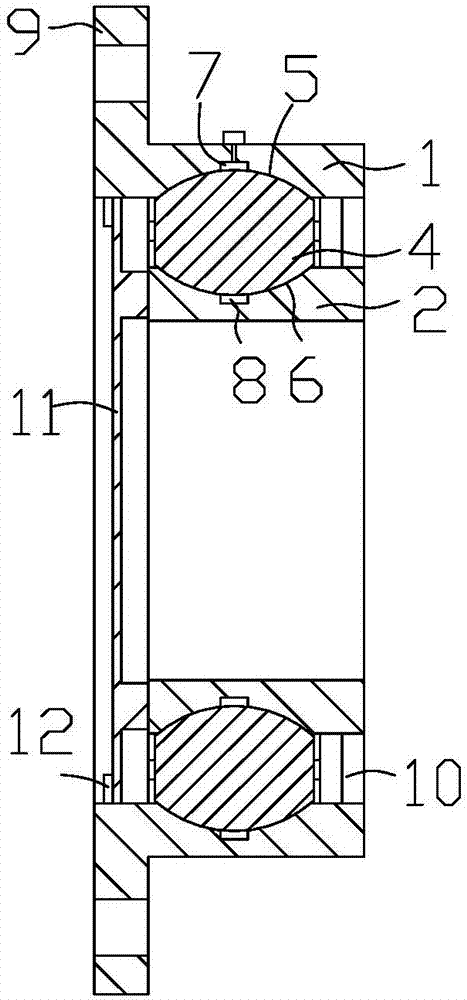

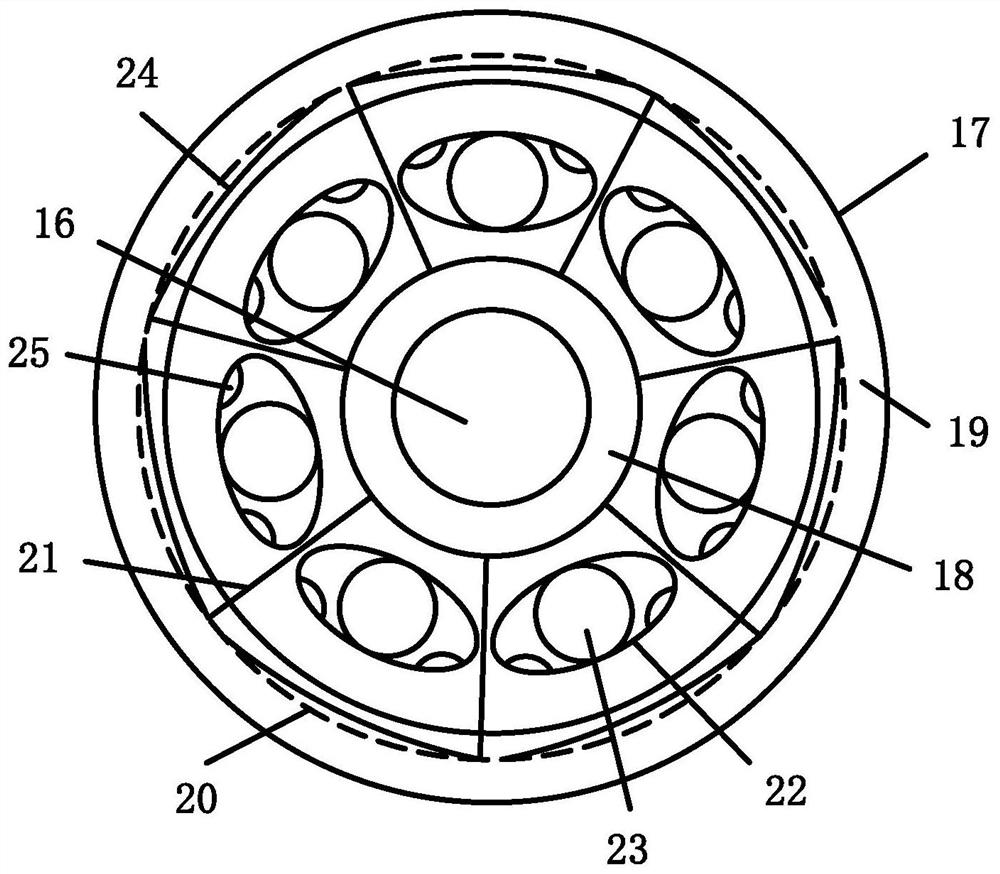

Hub module of mining equipment

InactiveCN107035774AImprove bearing capacitySatisfy the working conditions with large changes in bearing capacityBearing unit rigid supportInterference fitHeavy load

The invention discloses a hub module of mining equipment, and belongs to the technical field of bearing structures. The hub module comprises an outer ring and an inner ring for oppositely rotating; the inner ring is sleeved in the outer ring, and is coaxially arranged with the outer ring; a cage is arranged between the outer ring and the inner ring; a flange with a mounting hole is arranged at one end of the outer ring; the other end of the outer ring is leveled with the axial end surface of the inner ring; an annular inner slide way is peripherally formed in the inner side of the outer ring; an annular outer slide way is peripherally formed in the outer side of the inner ring; a slide body is arranged between the inner slide way and the outer slide way; the slide body comprises multiple slide blocks with arc structures; the slide blocks are provided with upper curved surface parts bonded corresponding to the outer slide way, and lower curved surface parts bonded corresponding to the inner slide way; a baffle plate is arranged in a shaft hole, at one end of the flange, of the outer ring; the baffle plate is extruded and pressed with the outer ring through a stop retainer ring; and the baffle plate is provided with an annular projection in interference fit with the axial end surface of the inner ring. The hub module adopts a full-contact surface rolling body, and can satisfy the use demands of a rotating part with low speed, heavy load and high load change in the process.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

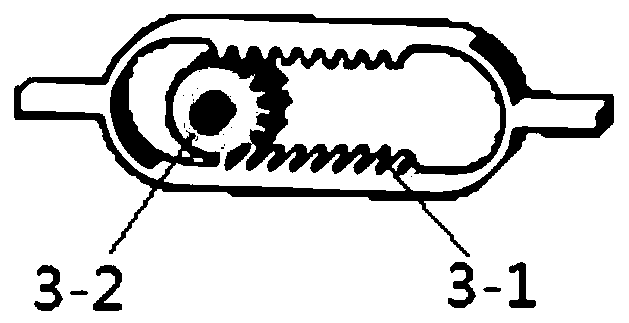

Automatic foam-roller muscle relaxation apparatus

PendingCN110368282AIncreased sorenessImprove scrolling effectVibration massageRoller massageMuscle relaxationRelaxation effect

The invention relates to an automatic foam-roller muscle relaxation apparatus, comprising a foam roller shaft, a base plate box, a driving motor, and a vibrating device. Intermittent gear-rack mechanisms are arranged on the two sides of the base plate box respectively; each intermittent gear-rack mechanism comprises a rack and an intermittent gear that is arranged inside the rack and engaged withthe rack; the intermittent gears on the two sides are connected the foam roller shaft on the base plate box respectively through support bars, wherein one intermittent gear is connectedly mounted on the driving motor of the base plate box; the vibrating device is arranged inside the foam roller shaft. The intermittent gear structures and the vibrating device enable relaxation effect to be more significant; massaging is provided for an exerciser at the premise of automation, so that the degree of comfort is amplified; material modifications enable the automatic foam-roller muscle relaxation apparatus to gain better safety and durability, cleaning is facilitated, and service life is extended.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Concrete paver for U-shaped water channel construction

ActiveCN111764351AImprove flatnessReciprocating swingArtificial water canalsFoundation engineeringRotational axisElectric machine

The invention discloses a concrete paver for U-shaped water channel construction. The concrete paver comprises a pave body. Slurry spray heads are symmetrically mounted on the two sides of the paver body. A U-shaped sliding frame is mounted on the paver body. A telescopic rod is mounted in the U-shaped sliding frame in a sliding manner, a compaction device is fixed to the outer side end of the telescopic rod, the inner side end of the telescopic rod is connected with a swing oil cylinder, and the swing oil cylinder is mounted on the paver body. The compaction device comprises a substrate connected with the telescopic rod, the substrate is connected with a vibration plate through first springs, a rotating motor is fixed to the inner side face of the vibration plate, an eccentric vibrator ismounted on a rotating shaft of the rotating motor, a scraping plate is hinged to the edge of the outer side face of the vibration plate, a connecting rod is in shaft connection to the scraping plate,a second spring is connected between the connecting rod and the scraping plate, the top end of the connecting rod is in shaft connection with a buffer oil cylinder, and the top end of the buffer oilcylinder is in shaft connection with the vibration plate. According to the concrete paver, the shortcomings in the prior art can be reduced, and high-quality concrete automatic paving is achieved in the U-shaped water channel.

Owner:吴晓强

Eager block fetching for web-based data grids

ActiveUS20140289673A1Improve scrolling effectDelay minimizationInterprogram communicationTransmissionEvent typeWeb browser

Owner:ORACLE INT CORP

Seismic prefabricated house

ActiveCN106049955BHigh sensitivityImprove scrolling effectProtective buildings/sheltersShock proofingDamping functionEngineering

The invention discloses an anti-seismic fabricated house. The anti-seismic fabricated house comprises a fabricated house body and a foundation. By the adoption of the anti-seismic fabricated house, the problem of poor anti-seismic performance is solved. A plurality of bases with buffering and damping functions are installed between a stand column and the foundation of the fabricated house. Each base comprises a first plate, a second plate and a third plate, wherein the first plate, the second plate and the third plate are arranged in parallel from top to bottom, a first installation part is arranged on the upper surface of the first plate, and an insertion plate and a buffering assembly are arranged between the first plate and the second plate, and an insertion plate and a buffering assembly are arranged between the second plate and the third plate. According to the anti-seismic fabricated house, the three plates of each base are in contact fit through the corresponding insertion plates arranged in a crossed mode, and the insertion plates and the three plates of each base are matched through cylindrical rollers, so that good rolling performance and guiding performance are achieved, rapid starting can be achieved in the initial stage of an earthquake, the sensitivity of the anti-seismic effect is improved, and the service life is prolonged.

Owner:河南省建筑工程质量检验测试中心站有限公司 +1

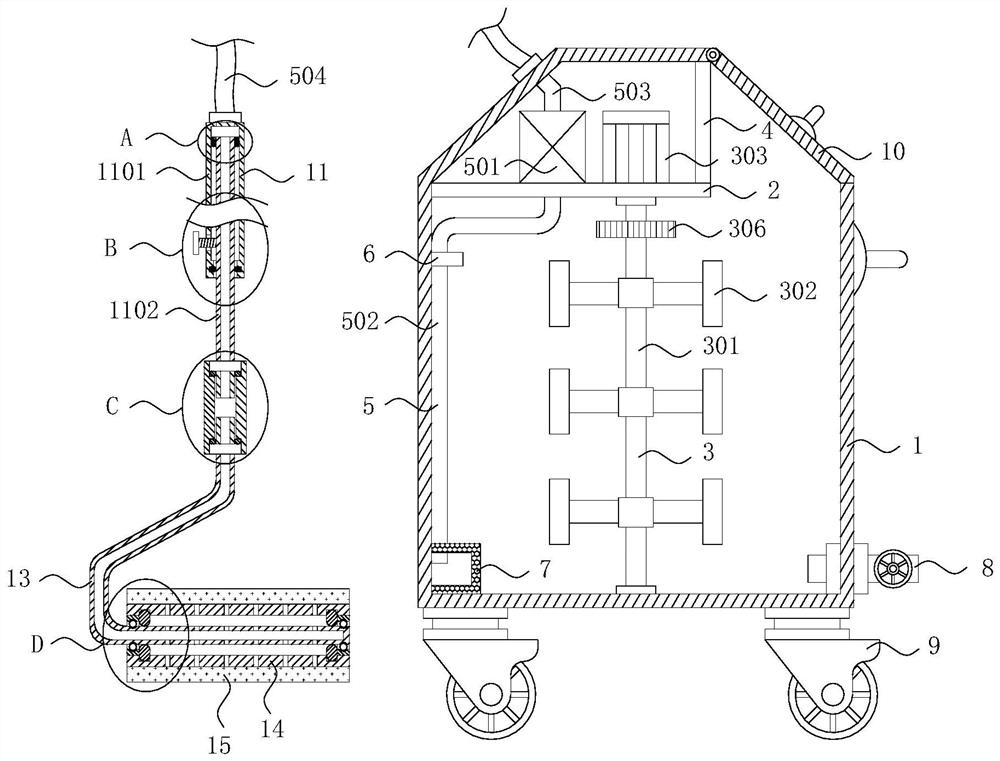

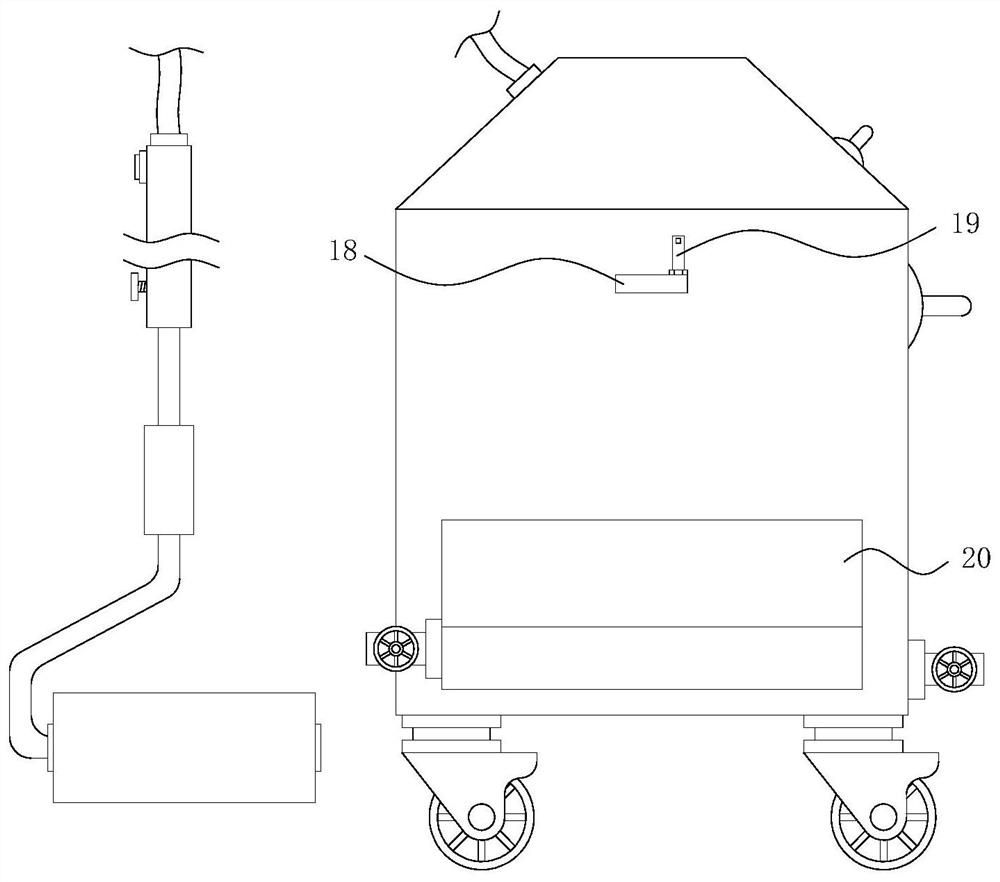

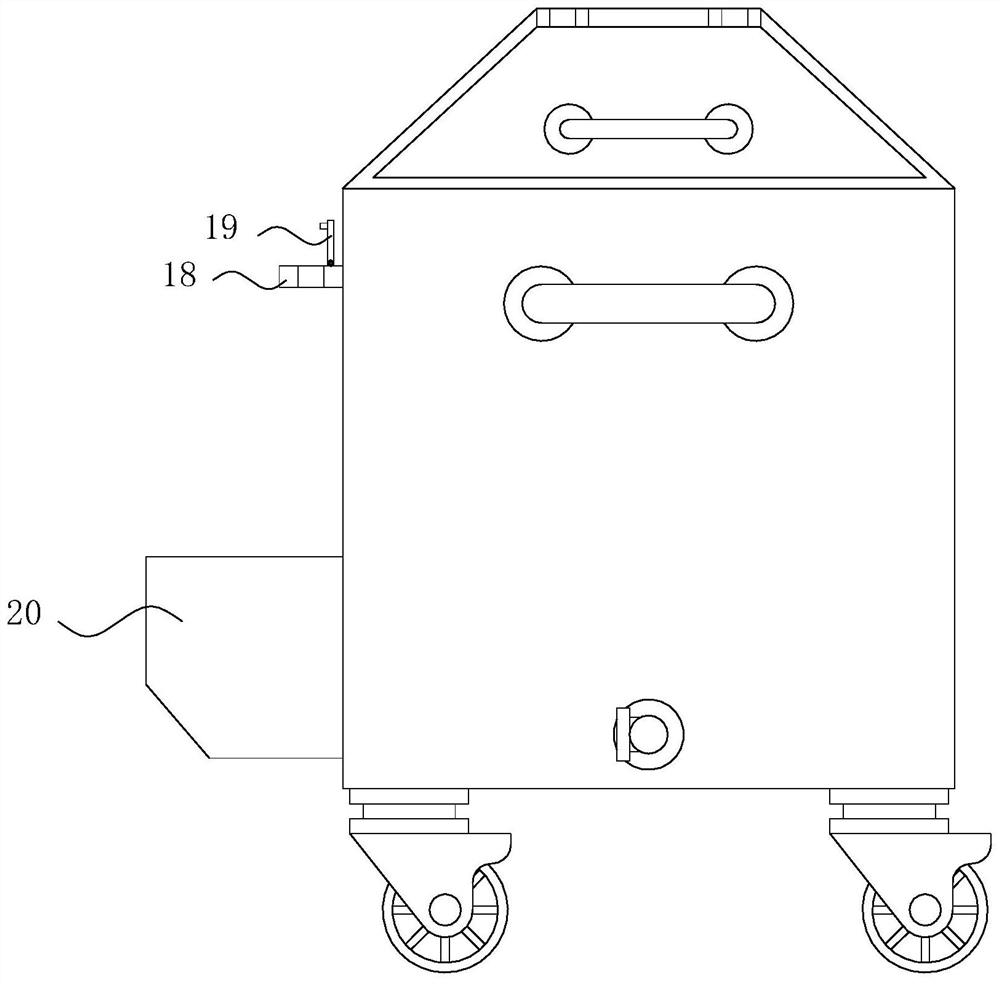

Portable automatic liquid supply roll coating device

InactiveCN112252672AWell mixedImprove smoothnessRotary stirring mixersTransportation and packagingGear wheelElectric machinery

The invention discloses a portable automatic liquid supply roll coating device, and relates to the technical field of roll coating. The portable automatic liquid supply roll coating device comprises adischarge box, wherein transverse plates are fixedly installed on the inner walls of the front and back sides of the discharge box. According to the portable automatic liquid supply roll coating device, rotating rods, stirring blades, a motor, a rotary rod, a first gear and second gears are used cooperatively, and the two groups of rotating rods are rotated in opposite rotating directions throughthe first gear and the two groups of second gears, so that internal latex paint and other required additives are mixed by the stirring blades, the additives and the latex paint are uniformly mixed, the roll coating effect is good, and the smoothness of a wall is increased; and a material suction pump, a material suction pipe, a discharge pipe and a hose are used cooperatively, so that the latex paint in the discharge box is extracted, a roller is automatically fed, the complexity of back-and-forth dipping of the roller is reduced, the labor intensity of manual dipping is reduced, and the wallpainting efficiency is improved.

Owner:湖州吴兴久虹机械有限公司

Highly saturated nitrile rubber composition and cross-linked rubber

ActiveUS10280298B2Improve scrolling effectMaintain good propertiesLayered productsThin material handlingCross-linkNitrile rubber

A highly saturated nitrile rubber composition containing a carboxyl group-containing highly saturated nitrile rubber (A1) which contains α,β-ethylenically unsaturated nitrile monomer units 15 to 60 wt % and α,β-ethylenically unsaturated dicarboxylic acid monoester monomer units 1 to 60 wt % and has an iodine value of 120 or less, a highly saturated nitrile rubber (A2) which contains α,β-ethylenically unsaturated nitrile monomer units 15 to 60 wt %, has a content of the α,β-ethylenically unsaturated dicarboxylic acid monoester monomer units of 0.9 wt % or less, and has an iodine value of 120 or less, and a polyamide resin (B), a content ratio of the carboxyl group-containing highly saturated nitrile rubber (A1) and the highly saturated nitrile rubber (A2) being a weight ratio of “carboxyl group-containing highly saturated nitrile rubber (A1):highly saturated nitrile rubber (A2)” of 2:98 to 98:2, is provided.

Owner:ZEON CORP

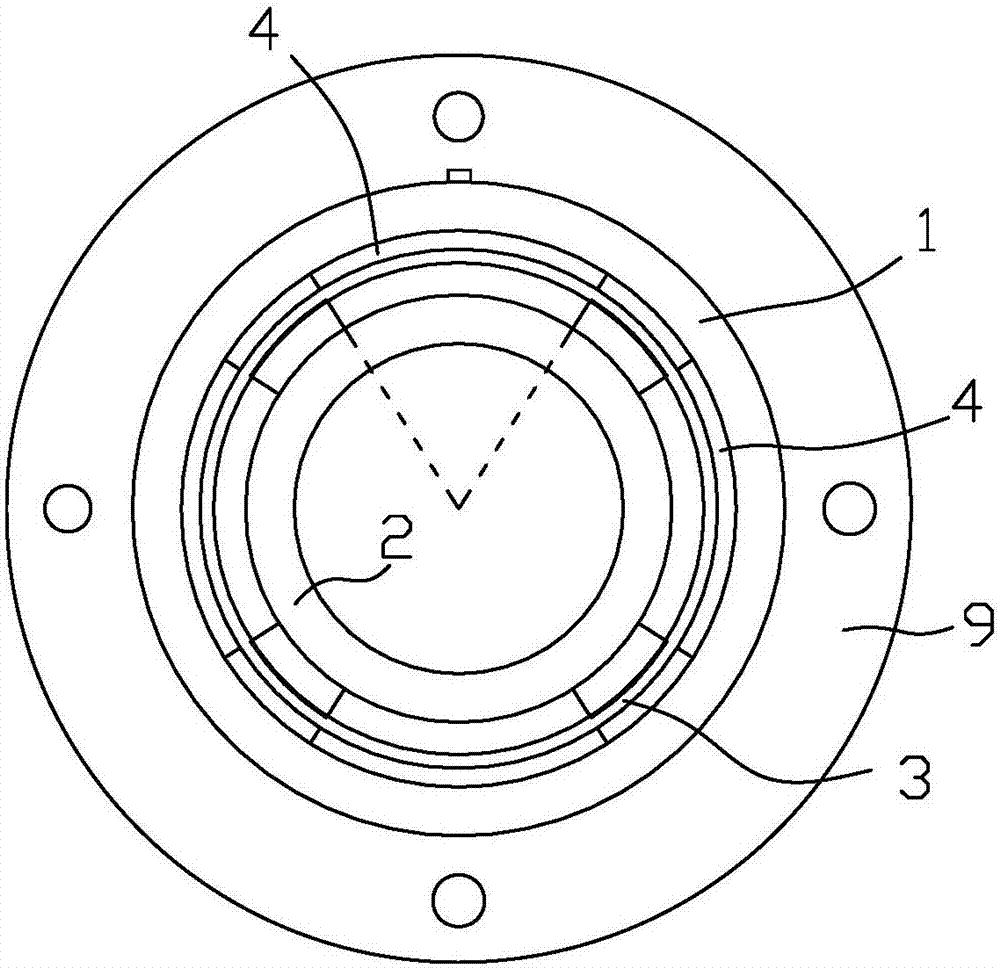

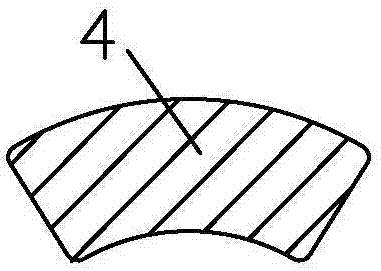

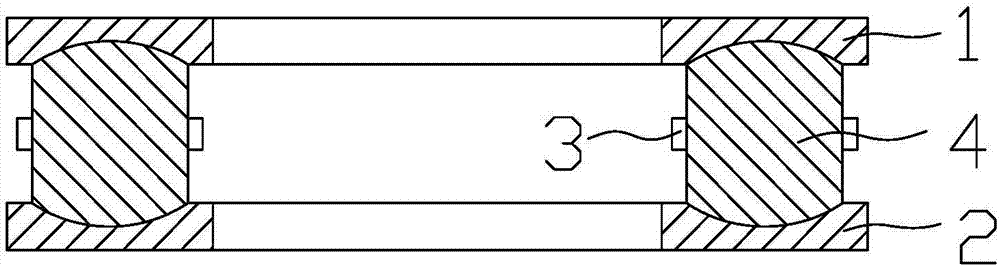

Bearing assembly

InactiveCN107165931AImprove bearing capacitySatisfy the working conditions with large changes in bearing capacityShaftsBearing componentsEngineeringMechanical engineering

The invention discloses a bearing assembly, and belongs to the technical field of bearing structures. The bearing assembly comprises an upper ring, a lower ring and cages, wherein the cages are located between an outer ring and an inner ring, and the upper ring and the lower ring correspond to each other in size and are arranged in a vertical coaxial mode. The bearing assembly is characterized in that an annular upper slide way is arranged on the lower end surface of the upper ring in the circumferential direction of the upper ring; an annular lower slide way is arranged on the upper end surface of the lower ring in the circumferential direction of the lower ring; a sliding body is arranged between the upper slide way and the lower slide way and comprises a plurality of sliding blocks which are of arc-shaped structures; upper curved surface parts which are correspondingly attached to the upper slide way surface and lower curved surface parts which are correspondingly attached to the lower slide way surface are arranged on the sliding blocks; and the cages are provided with placement positions for sleeving of the corresponding sliding blocks, and a lubricating chamber is arranged between every two adjacent sliding blocks. According to the bearing assembly, the sliding body capable of sliding is arranged and replaces a rolling body in the prior art, so that the bearing capacity of a bearing adopting the sliding body is large, and the bearing is suitable for slow running and capable of meeting the working condition with large bearing capacity change.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Assembled transformer room

ActiveCN106088767AHigh sensitivityImprove scrolling effectTransformer housesBuilding constructionsTransformerEngineering

The invention discloses an anti-seismic assembled transformer room. The assembled transformer room comprises a transformer room body and a foundation; a plurality of bases with buffering and shock absorption effects are installed between the bottom face and the foundation of the assembled transformer room, the bases are located at four turning corners, and each base comprises a first plate, a second plate and a third plate which are arranged in parallel from top to bottom; the second plates, the first plates and the third plates form oscillation structures through insertion plates with a frictional speed reduction effect. According to the assembled transformer room, the three plates of each base are in contact fit through the crossed insertion plates which are in roller fit with the three plates, therefore, the assembled transformer room has good rolling performance and guiding performance and can be started quickly at the initial stage of an earthquake, the sensitivity of anti-seismic efficiency is improved, and the service life is prolonged.

Owner:江苏圆融建筑工程有限公司

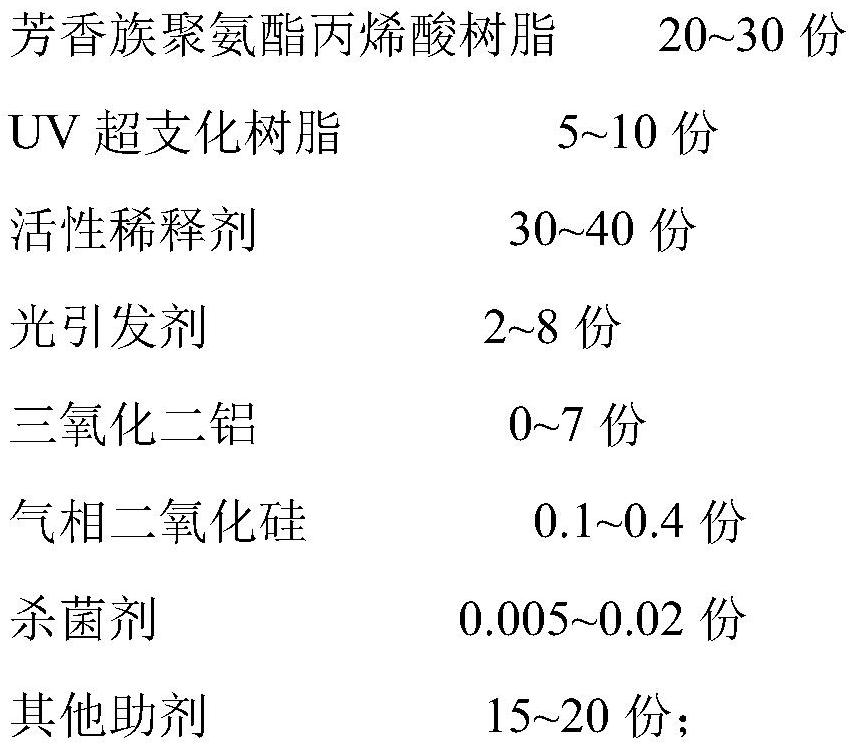

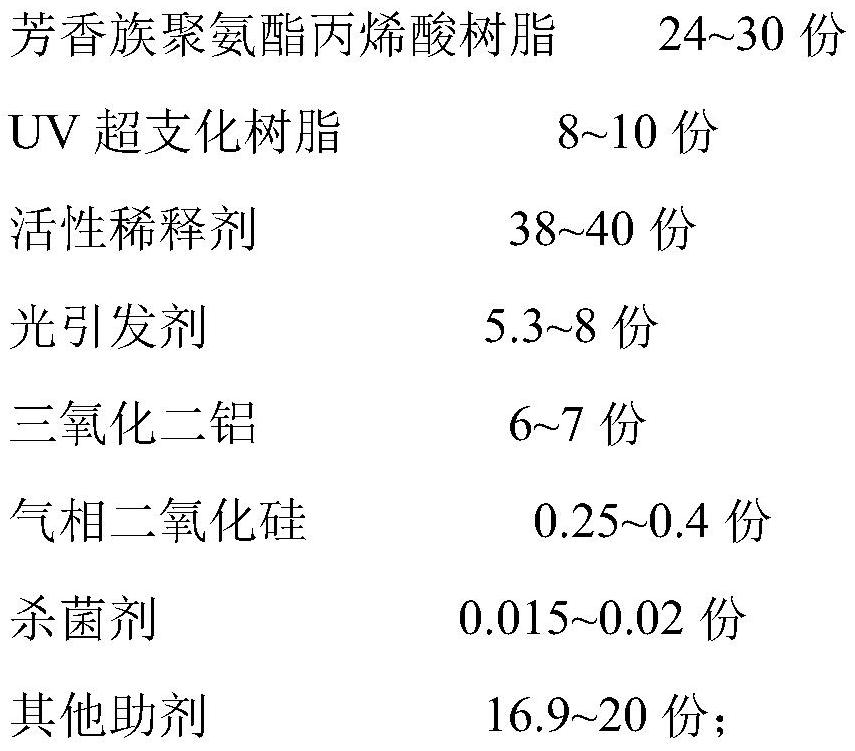

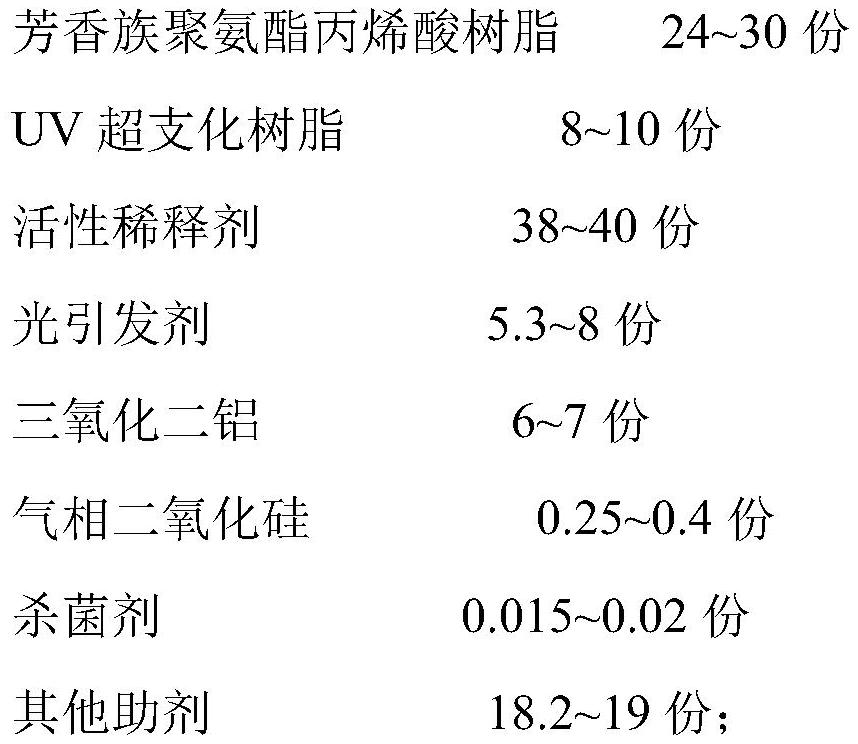

UV antibacterial and mildew-proof finish paint and preparation method thereof

InactiveCN112194977AImprove curing speedImprove stabilityAntifouling/underwater paintsPaints with biocidesPolymer scienceAcrylic resin

The invention relates to the field of UV coatings, and particularly discloses a UV antibacterial and mildew-proof finish paint and a preparation method thereof. The UV antibacterial and mildew-proof finish paint is prepared from aromatic polyurethane acrylic resin, UV hyperbranched resin, a reactive diluent, a photoinitiator, aluminum oxide, fumed silica, a bactericide and other auxiliary agents in certain parts by mass, the preparation method comprises the following steps: mixing the aromatic polyurethane acrylic resin, the UV hyperbranched resin and part of the components of the reactive diluent, then adding the photoinitiator and part of the components of other auxiliary agents, performing mixing, adding the fumed silica and the other components in the other auxiliary agents and the other components in the reactive diluent, and performing mixing, and finally, adding the rest components of the reactive diluent, the rest components of the other auxiliary agents and the bactericide, and uniformly mixing the substances to obtain the UV antibacterial and mildew-proof finish paint. The UV antibacterial and mildew-proof finish paint can be used for coating the surfaces of various indoor and outdoor objects, and has the advantage of excellent yellowing resistance.

Owner:SHANGHAI CHANGRUNFA PAINT

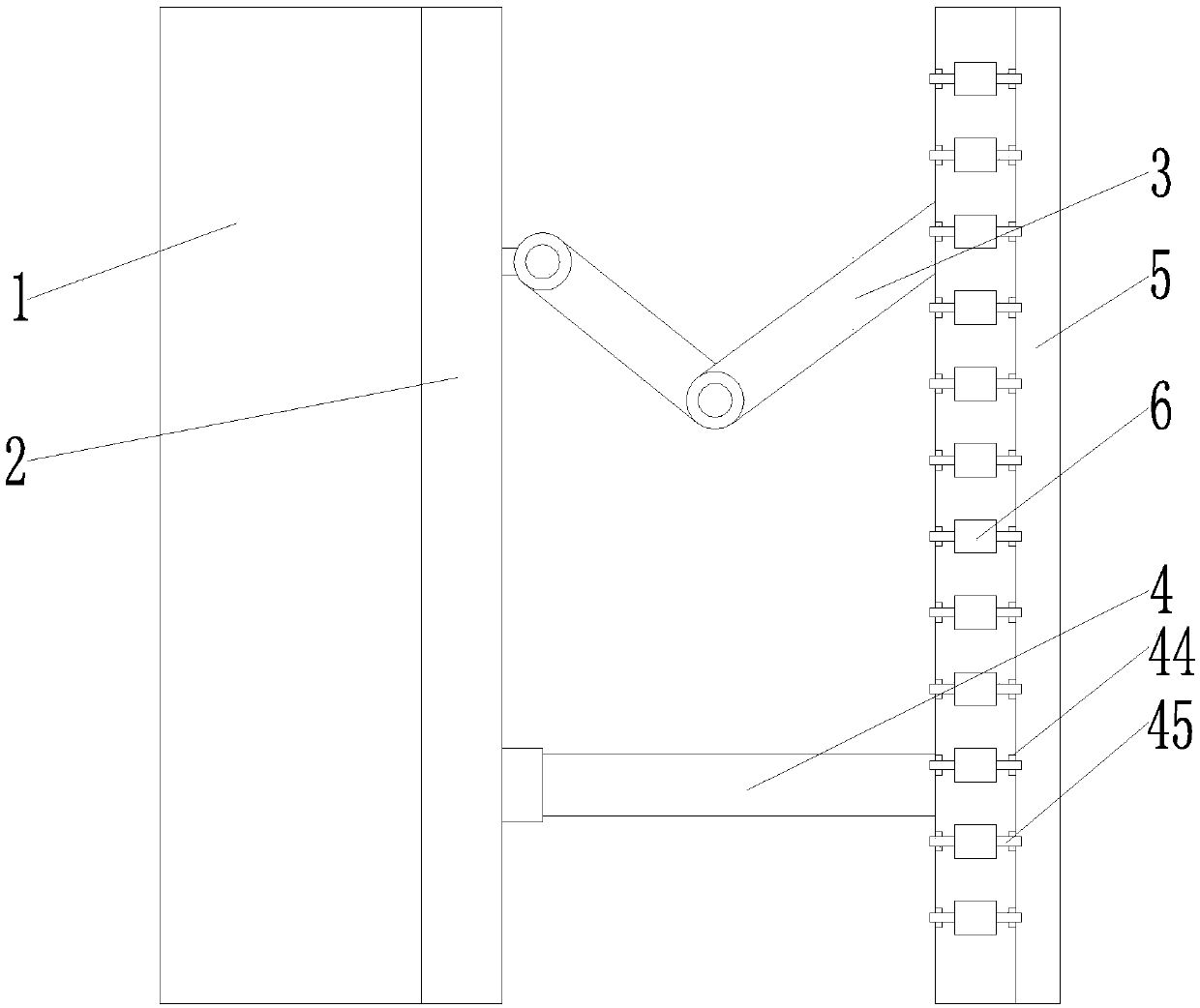

Equipment for panel conveying

PendingCN107600932AFlexible adjustmentRegulation stabilityMechanical conveyorsRoller-waysEngineering

Owner:浙江云峰莫干山家居用品有限公司

A transmission mechanism for solar panels

ActiveCN112495824BRealize separate transmissionEasy accessFinal product manufactureSortingEngineeringComputer science

Owner:山西晋通送变电有限公司

Anti-overturning high-voltage transmission line tower

ActiveCN106168078BChange vibration frequencyChange the vibration amplitudeTowersDamping functionEngineering

The invention discloses an anti-overturning high-tension transmission line iron tower used for solving the problem that an iron tower is prone to overturning. The iron tower comprises an iron tower body and a transition part, and the middle portions of the iron tower body are disconnected and movably connected through the transition part, with buffering and damping functions, on the corner. The transition part comprises a first plate, a second plate and a third plate which are arranged in parallel from top to bottom, wherein the portion between the first plate and the second plate and the portion between the second plate and the third plate are each designed to be a buffering structure with a brake structure. As the lower middle portions of the iron tower are disconnected and provided with the transition part, the portion prone to bending in the iron tower shifts in the horizontal direction in the presence of the transition part, in the shifting process, vibrating energy is consumed through effective friction, vibrating frequency and amplitude are changed, bending is avoided, the method of increasing the use amount of profile steel to improve strength traditionally is changed, and the seismic resistance is improved by 40% without changing the steel amount.

Owner:连云港强连铁塔制造有限公司

Rolling brush device and method of use thereof

The invention relates to a rolling brush device and a using method thereof. The rolling brush device comprises a supporting frame, an eccentric roller, a shell body, a piston structure and a brushingstructure, wherein the supporting frame comprises a pair of supporting rods which are arranged oppositely and connected with each other; the eccentric roller is rotatably arranged between the pair ofsupporting rods, and a liquid inlet flow channel used for delivering a rolling brush liquid is formed in the interior of the eccentric roller; the shell body is fixedly arranged on the eccentric roller in a sleeving mode, and a piston cavity which communicates with the liquid inlet flow channel and is formed in the radial direction of the eccentric roller is formed in the shell body; the end partof the piston structure is embedded in the eccentric roller, and the piston structure is movably arranged in the piston cavity; and the brushing structure is fixedly arranged at the outer circumference of the shell body in an inserting mode and communicates with the piston cavity. The eccentric roller is driven to rotate eccentrically when the shell body rolls, and then the piston structure is driven to reciprocate in the piston cavity, so that the rolling brush liquid in the liquid inlet flow channel is absorbed into the piston cavity, and the uniformity of painting can be effectively ensured.

Owner:中建八局西北建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com