A high-efficiency energy-saving low-carbon manganese sphere production process

A production process, high-efficiency and energy-saving technology, applied in the field of manganese-based metallurgical additives, can solve problems such as geometric size, poor uniformity of apparent density and chemical composition, high energy consumption in the production of fused manganese ingots, and irregular geometric shapes, etc., to achieve the elimination of safety Hidden danger, small deformation, good density consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of embodiment of the present invention, product adopts following raw material and process to make:

[0021] (1) Take 95 kg of low-carbon (≤0.03%) low-sulfur (≤0.03%) electrolytic manganese metal sheets with a manganese content of 99.5%, roll them into powder, and pass through a 20-mesh standard sieve;

[0022] (2) Take 5 kilograms of inorganic binders that do not contain elements such as S, P, and C, and add them into the manganese powder obtained in step (1), stir quickly in a bowl mixer for 30 seconds, and obtain the mixture for subsequent use;

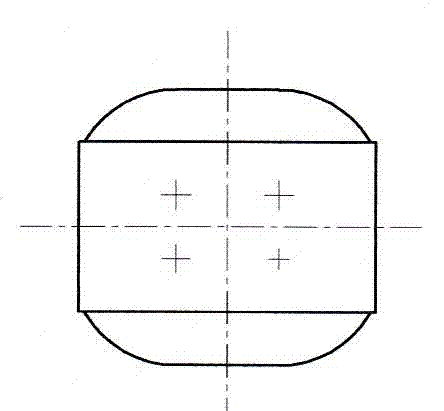

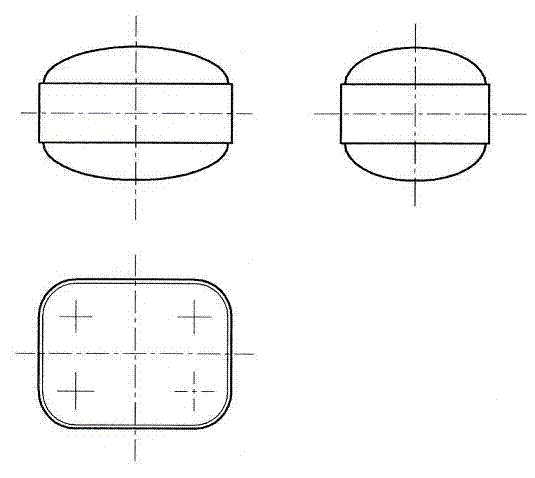

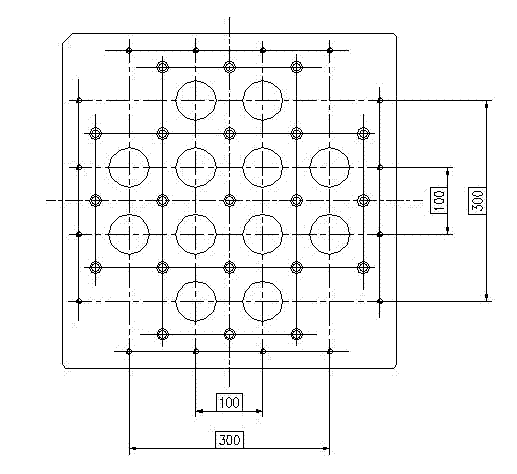

[0023] ⑶. Put the mixture obtained in step ⑵ on average into a 12-station pull-down forming die and press it into a compact within 20 to 30 minutes. The shape of the compact is a double spherical crown cylinder (maximum size 33mm), and the single compact The piece weight is 80 grams;

[0024] ⑷. Put the compact obtained in step ⑶ in a baking room equipped with a fan and a circulating exhaust fan wit...

Embodiment 2

[0027] Embodiment 2: Another kind of embodiment product of the present invention adopts following raw material and process to make:

[0028] (1) Take 97 kg of low-carbon (≤0.03%) low-sulfur (≤0.03%) electrolytic manganese metal sheets with a manganese content of 99.7%, roll them into powder, and pass through a 40-mesh standard sieve;

[0029] (2) Add 3 kilograms of inorganic binders that do not contain elements such as S, P, and C, and add them into the manganese powder obtained in step (1), stir quickly in a bowl mixer for 50 seconds, and obtain the mixture for subsequent use;

[0030] ⑶. Put the mixture obtained in step ⑵ on average into a 12-station pull-down forming mold and press it into a compact within 20 to 30 minutes. The shape of the compact is 26×20×15 square chewing gum, and the weight of a single compact 90 grams;

[0031] ⑷. Put the compact obtained in step ⑶ in a baking room equipped with a fan and a circulating exhaust fan within 5 to 6 hours, and bake it at 2...

Embodiment 3

[0034] Embodiment 3: another kind of embodiment product of the present invention adopts following raw material and process to make:

[0035] (1) Take 96.5 kg of low-carbon (≤0.03%) low-sulfur (≤0.03%) electrolytic manganese metal sheets with a manganese content of 99.6%, roll them into powder, and pass through a 30-mesh standard sieve;

[0036] (2) Take 3.5 kilograms of inorganic binders that do not contain elements such as S, P, and C, and add them into the manganese powder obtained in step (1), stir rapidly in a bowl mixer for 40 seconds, and obtain the mixture for subsequent use;

[0037] ⑶. Put the mixture obtained in step ⑵ on average into a 12-station pull-down forming die and mold it into a compact within 20 to 30 minutes. The shape of the compact is 26×20×20 square chewing gum, and the weight of a single compact 85 grams;

[0038]⑷. Put the compact obtained in step ⑶ in a baking room equipped with a fan and a circulating exhaust fan within 5 to 6 hours, and bake it at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com