Automatic machining device for curved needle crank of sewing machine and machining method of automatic machining device

An automatic processing and sewing machine technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as large wear of the looper crank, large demand for copper connecting rods, and long working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

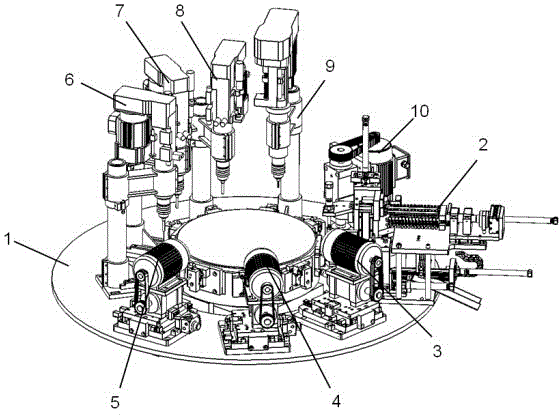

[0088] like figure 2 As shown, the automatic processing device of the sewing machine looper crank of the present invention includes a turntable workbench 1, and the turntable workbench 1 is respectively provided with an automatic loading and unloading module 2, a small end point hole module 3, and a small end end drilling module along the circumferential direction. 4. Reaming module 5 at the small end, spot-spotting module 6 at the large end, first drilling module 7 at the large end, second drilling module 8 at the large end, tapping module 9, and sawing module 10 at the large end.

[0089] like Figure 4 As shown, the turntable workbench 1 includes a processing workbench 1-1, and the center of the processing workbench 1-1 is provided with a nine-square turntable 1-2, and the turntable 1-2 is uniformly fixed with nine looper crank fixtures 1 along the circumferential direction. -3; Automatic loading and unloading module 2, small end point hole module 3, small end drilling mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com