Adjustable sorting detecting grinding machine

A grinding machine and sorting technology, which is applied in the direction of grinding machines, grinding bed, sorting, etc., can solve the problems that affect the processing quality of workpieces, easily produce defective products, and inaccurate positioning, so as to achieve clamping and fastening and ensure processing quality , precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

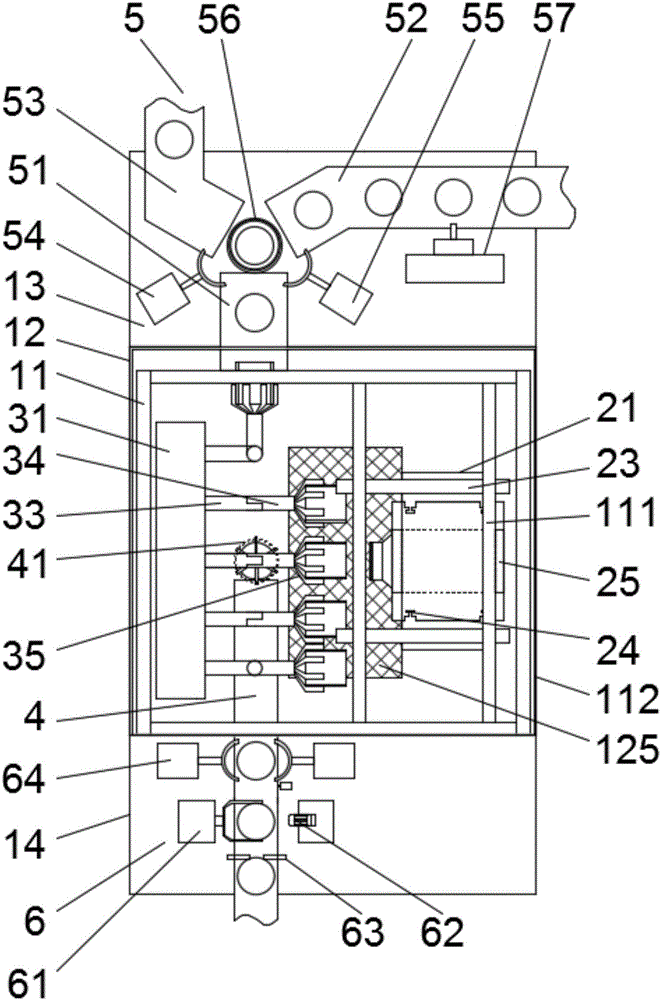

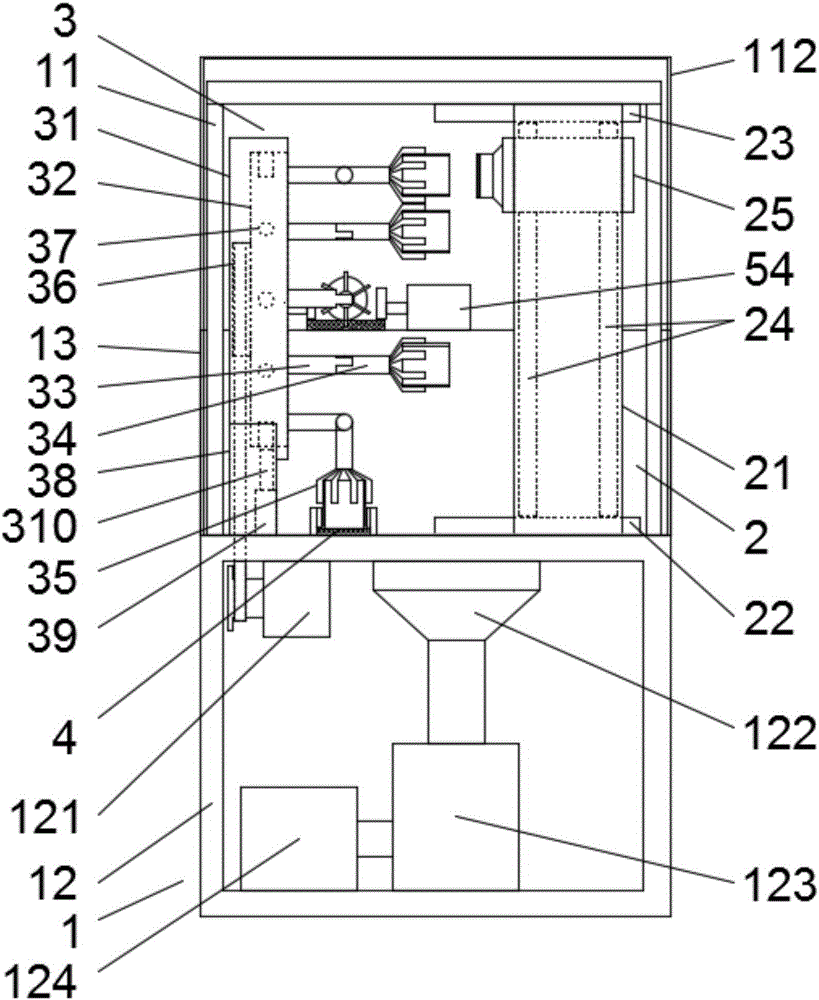

[0014] Such as figure 1 with figure 2 Shown, a kind of grinder of adjustable sorting detection, it comprises frame 1; Described frame 1 comprises lower frame 12 and frame 11 on grinder; The frame 11 on described grinder is provided with grinding device 2 and a turntable clamping device 3; the top of the frame 11 on the grinding machine is provided with two upper beams 111; the outside of the frame 11 on the grinding machine is provided with a glass cover 112 for protection; the grinding device 2 includes a fixed frame 21; the bottom of the fixed frame 21 is provided with a lower X-axis slide rail 22; the top of the fixed frame 21 is provided with an upper X-axis slide rail 23 on the upper beam 111; the inside of the fixed frame 21 is provided with a Y axis slide rail 24; the Y-axis slide rail 21 is provided with a grinding wheel device 25; the turntable clamping device 3 includes a turntable shell 31 and a clamping turntable 32 located inside the turntable shell 31 and axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com