A non-contact liquid filling method for controlling liquid level

A non-contact, liquid control technology, applied in automatic control of packaging, liquid materials, packaging, etc., can solve problems such as inability to accurately control liquid level height, and achieve the effect of ensuring accuracy, eliminating influencing factors, and ensuring accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

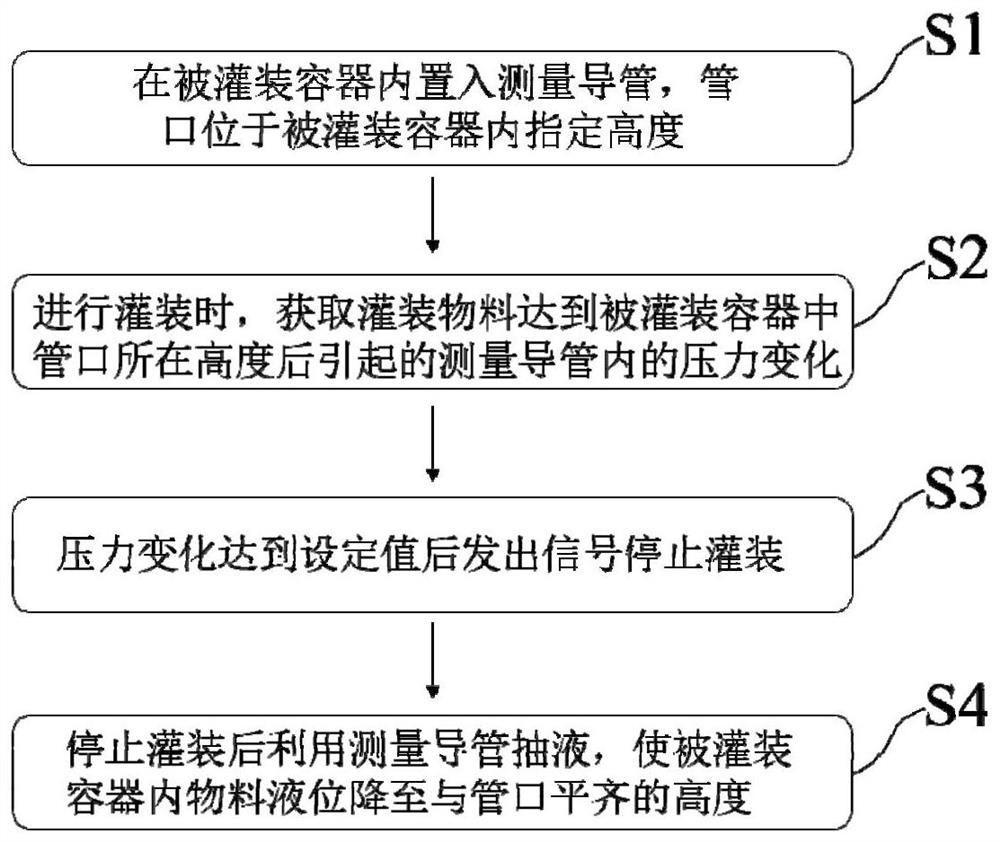

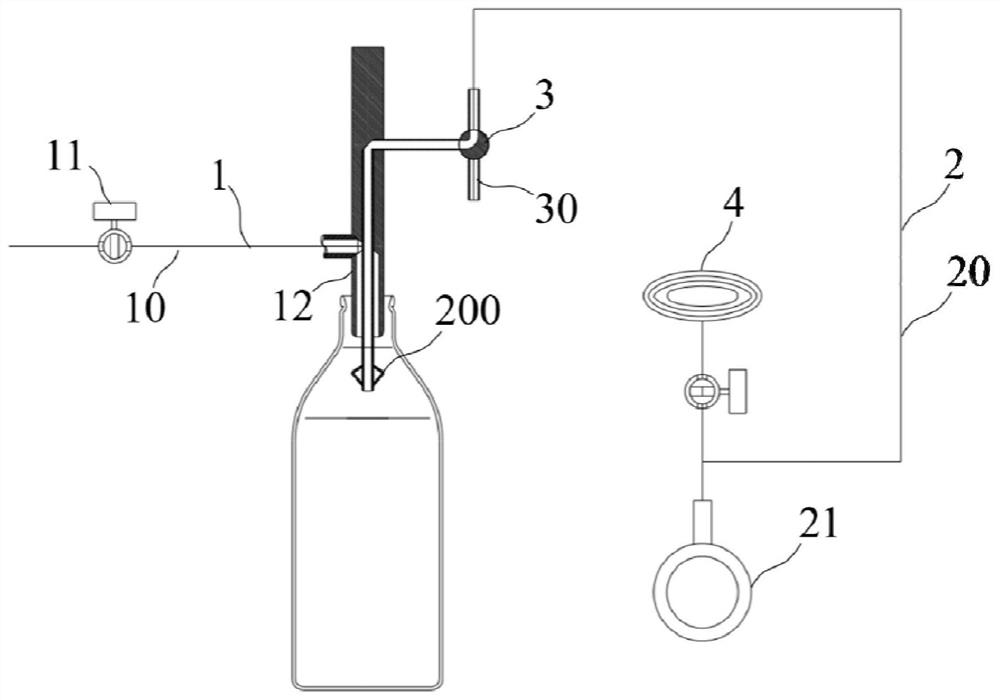

[0058] Such as figure 1 As shown, the non-contact liquid filling control method of this embodiment includes the following steps:

[0059] S1. Insert a measuring conduit 20 into the container to be filled, and the nozzle is located at a specified height in the container to be filled;

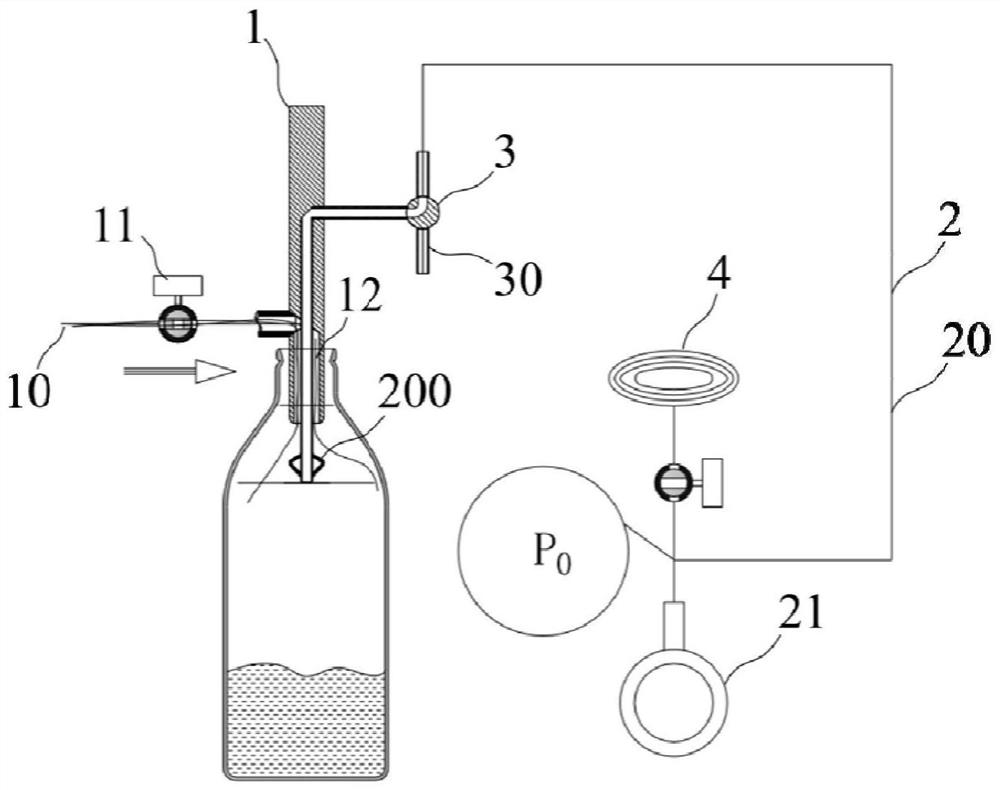

[0060] S2. When filling, obtain the pressure change in the measuring conduit 20 caused after the filled liquid material reaches the specified height of the filled container;

[0061] S3. After the pressure change reaches the set value, a signal is sent to stop filling.

[0062] Due to the inevitable errors in the cavity structure of the filled container, especially the glass and ceramic containers, the error is greater, and the traditional filling device can only achieve accurate control of the flow rate, and cannot vary the volume. The container is filled with high consistency of liquid level. The existing filling method to control the high consistency of liquid level is to use photoelectric s...

Embodiment 2

[0075] Such as figure 1 As shown, the non-contact liquid filling method of this embodiment is further improved on the basis of Embodiment 1, and further includes:

[0076] S4. After the filling is stopped, use the measuring conduit 20 to draw liquid, so that the liquid level of the liquid material in the container to be filled is reduced to a height equal to the mouth of the nozzle.

[0077] Through the method of Example 1, after the filling is completed, the liquid level in each container on the same assembly line can be basically guaranteed to be equal, but there are two factors that may cause height errors: one is when the filling is stopped, the unfinished liquid The material continues to fall, and an error will be generated at this time. The second is that the increase in the liquid level in the period from the time when the liquid level of the filling liquid material is in place to the triggering of the pressure sensor will cause an error. In theory, when the parameters ...

Embodiment 3

[0082] The non-contact liquid filling method of this embodiment is further improved on the basis of Embodiment 2. After the height of the measuring conduit 20 is set, its position is fixed, and the nozzle is controlled by moving and lifting the filled container. The height within the container being filled.

[0083] In this embodiment, the height of the measuring conduit 20 is fixed after being determined. When filling each time, the container to be filled is moved to directly below the measuring conduit 20, and then the container to be filled is raised so that the measuring conduit 20 The relative height in the filling container is consistent with the previous relative height, thereby ensuring accurate and consistent control of the liquid level for each filling.

[0084] For the method of the present application, since the measuring conduit 20 and a series of devices connected to it are relatively bulky in structure compared with the container to be filled, it is not appropri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com