Water spray test device

A test device and water splashing technology, applied in the mechanical field, can solve the problems of poor test reproducibility, different test results, and very large influence, and achieve the effect of ensuring accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

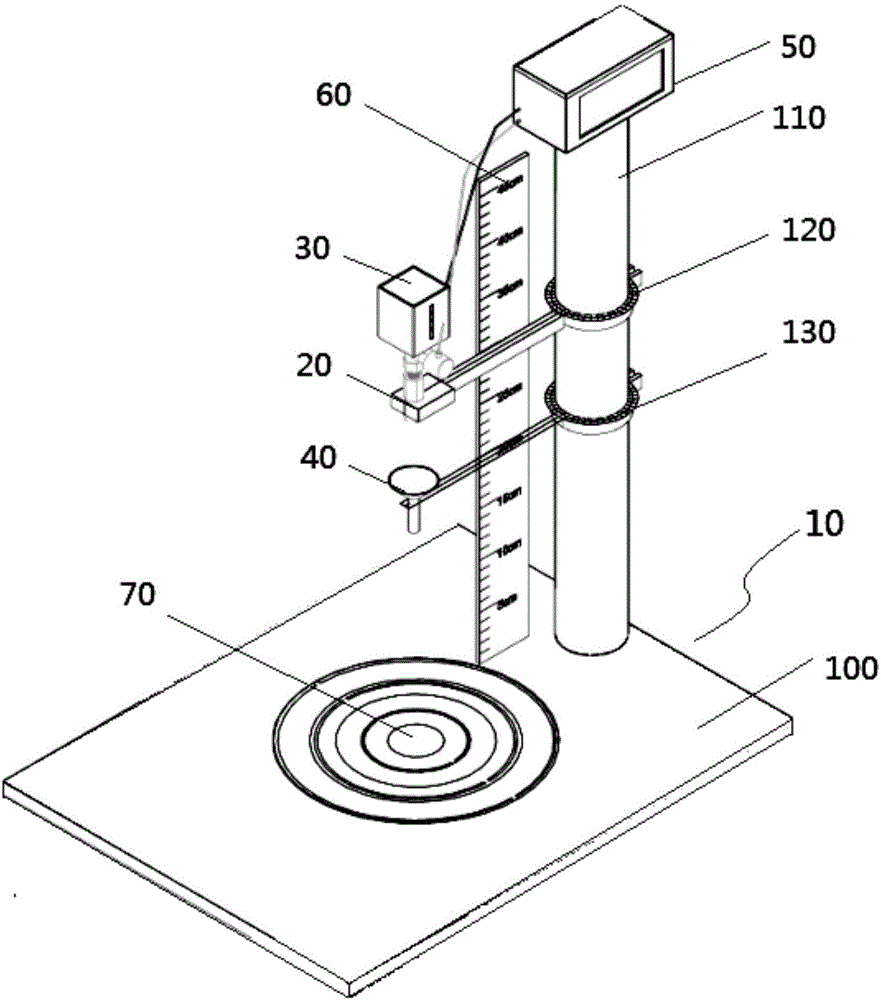

[0019] Such as figure 1 A kind of splash test device shown, comprises support platform 10, container 20, control valve 30, funnel 40 and controller 50, and described support platform is by a platform base 100, is located at the vertical on described platform base 100 The column 110 and the first clamp 120 and the second clamp 130 on the column 110 are composed. The first clamp 120 located at the bottom of the column 110 clamps the funnel 40, and the funnel 40 is placed vertically. The second clamp 130 located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com