Finished piece positioning method for grinding die of automobile outer cover panel

A technology of outer cover and positioning method, applied in positioning devices, manufacturing tools, metal processing machine parts, etc., can solve the problems of surface defects, difficult to ensure the accuracy of CH holes, and the inability to accurately transfer the grinding and datum, and achieve the guarantee Consistency and accuracy, the effect of avoiding surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A method for locating parts used in researching molds of automobile outer covering parts, adopting transition process holes in the researching molds of automobile outer covering parts, and the implementation steps are as follows:

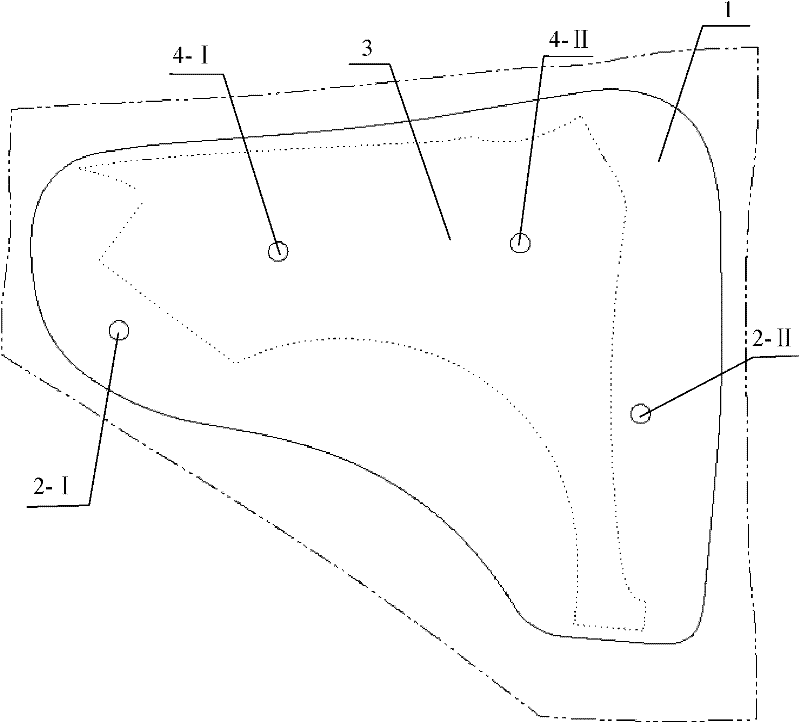

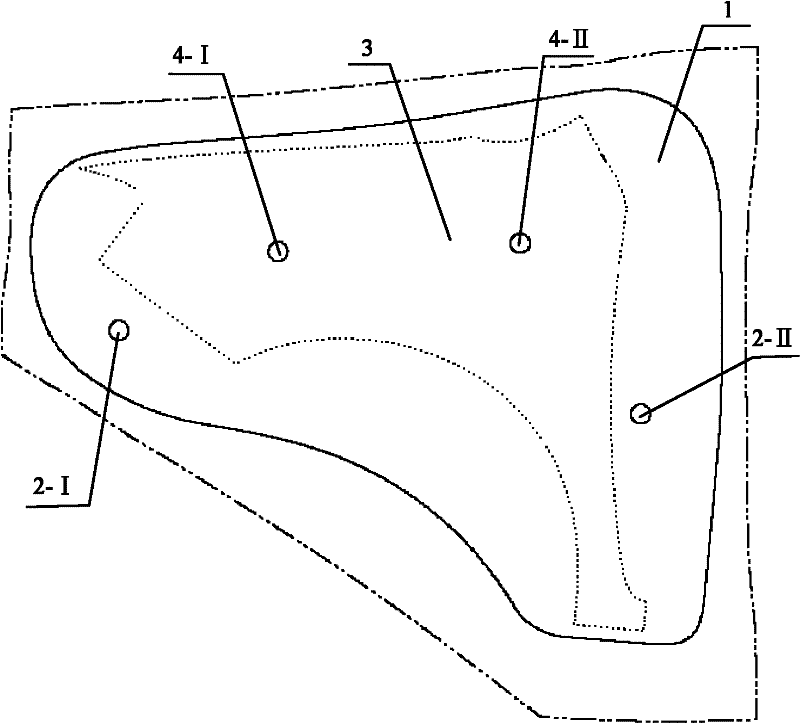

[0019] 1) Punch out two transition process holes ch-I, ch-II 2-I, 2-II on the non-A type surface 1 after the parts are ground and stabilized, and transition process holes ch-I, ch-II 2-I , The position of 2-II is in the non-exposed area of the workpiece and not in the waste area of the next process;

[0020] 2) Use the transition holes ch-I, ch-II 2-I, 2-II on the above-mentioned non-type A surface 1 to carry out research and integration, and punch at least two positioning process holes CH- on the A type surface 2 of the workpiece. I, CH-II 4-I, 4-II, when punching the positioning process holes CH-I, CH-II4-I, 4-II, the transitional process holes ch-I, ch-II 2-I cannot be punched , The sheet at 2-II is repaired;

[0021] 3) Afterwards, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com