Aluminum alloy riveted subway vehicle side wall general assembly welding flexible chemical equipment

An aluminum alloy and vehicle side technology, which is applied in the field of aluminum alloy riveted metro vehicle side wall general assembly welding flexible chemical equipment, can solve the problems of side wall general assembly welding equipment such as poor versatility, low reliability, and high cost, and achieve The effect of shortening the preparation period, shortening the switching time, and reducing the cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

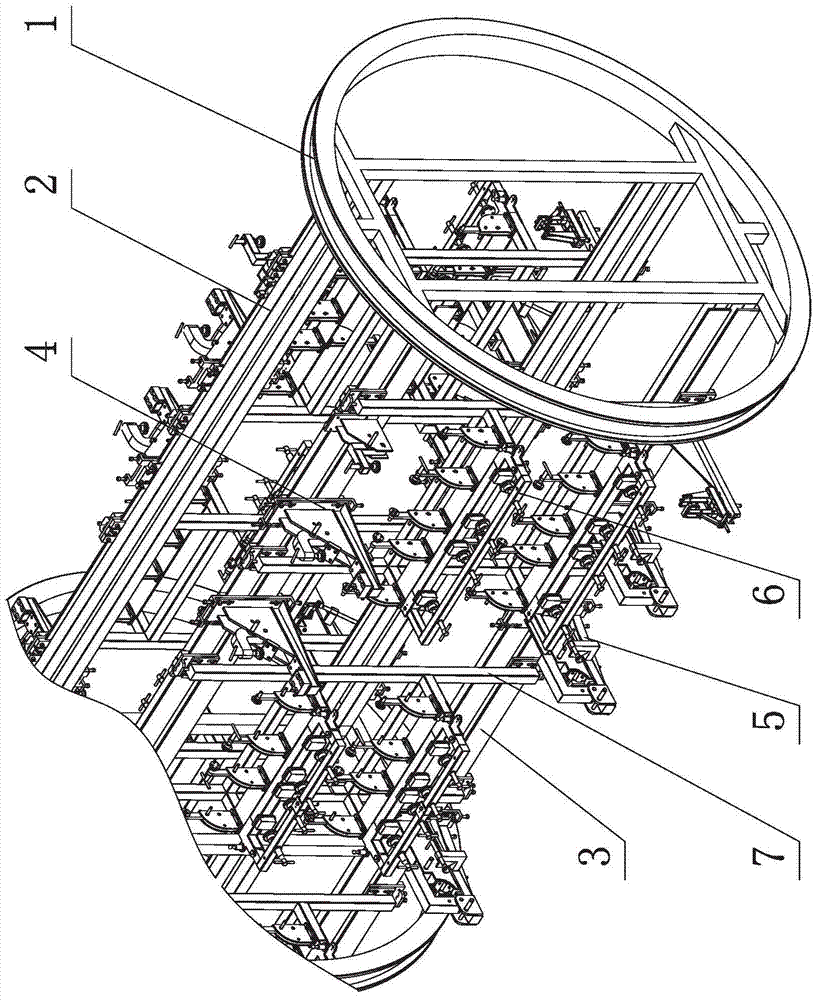

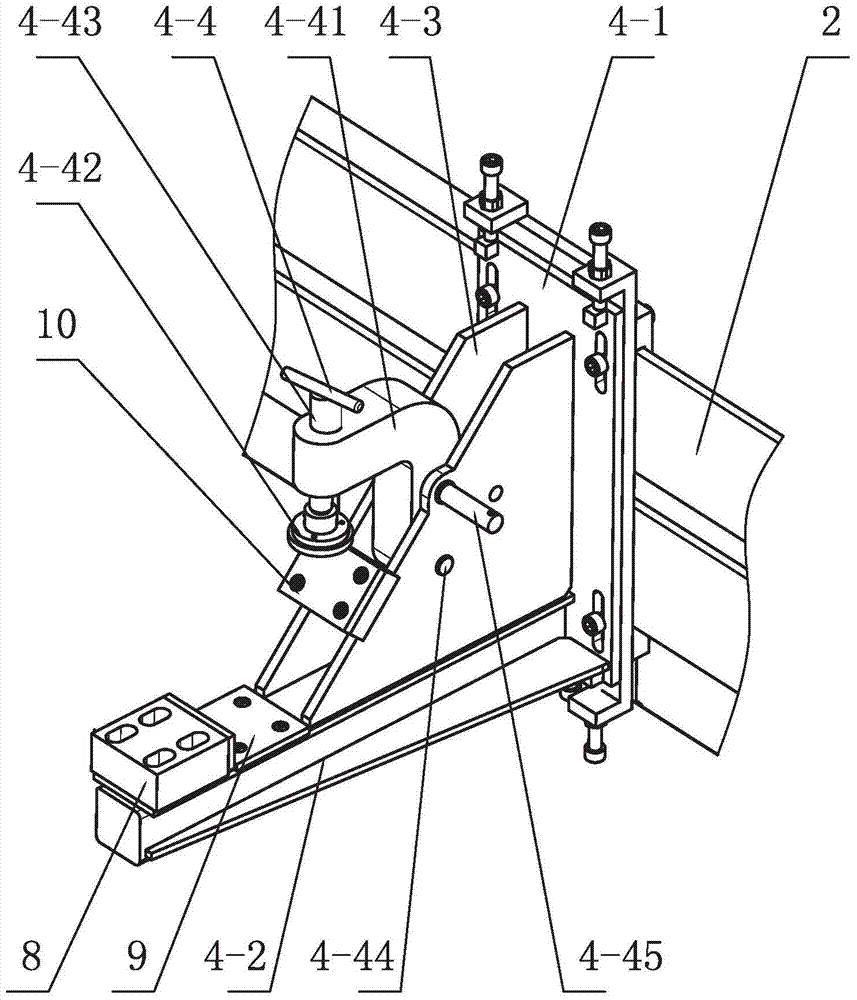

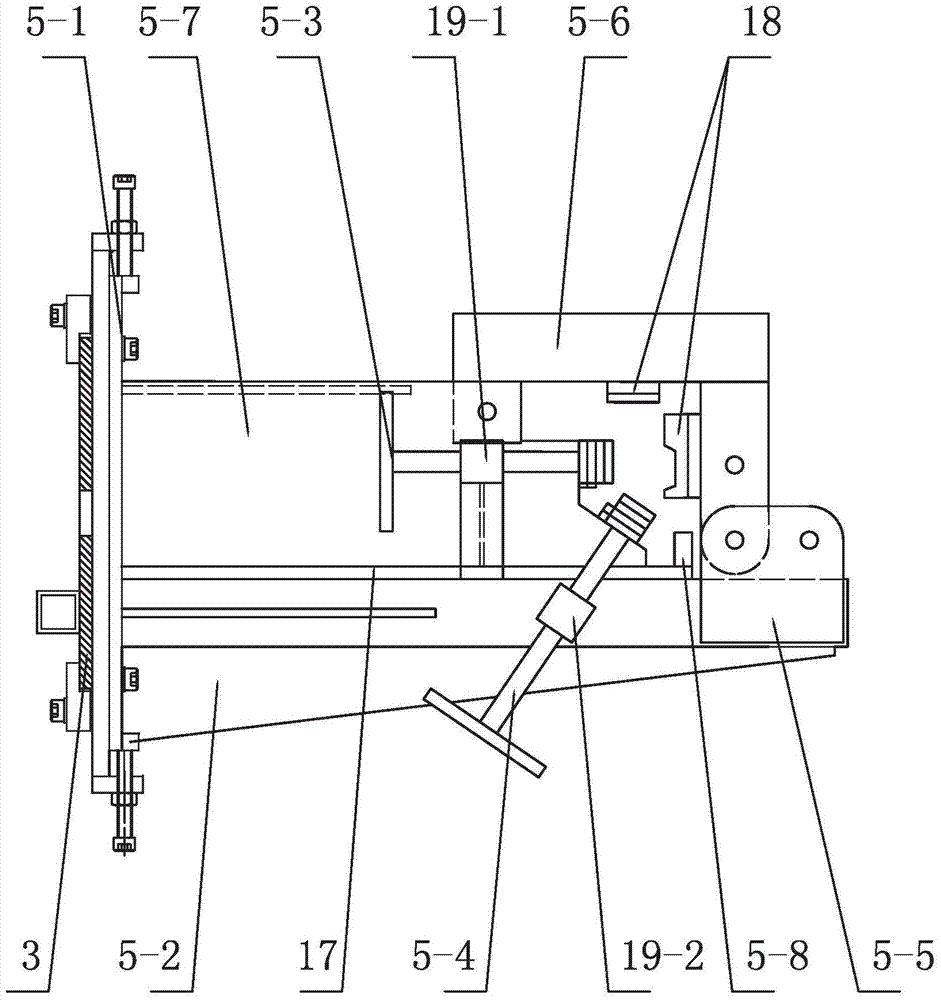

[0018] Such as figure 1 As shown, it is a structural schematic diagram of the present invention. The aluminum alloy riveted subway vehicle side wall general assembly welding flexible chemical equipment includes at least two annular handwheels 1, two sets of side wall tooling mechanisms are arranged between the annular handwheels 1, and the two tooling The mechanism is set symmetrically front and back. The side wall tooling mechanism includes an upper fixing plate 2 and a lower fixing plate 3 arranged in parallel. Several sets of upper side beam clamps 4 are arranged on the upper fixing plate 2 , and lower side beam clamps 5 are arranged on the lower fixing plate 3 corresponding to the upper si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com