Friction stir welding device for 2219 aluminum alloy panel

A friction stir welding and aluminum alloy sheet technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of high energy consumption, large loss of stir welding joints, and unreliable welding connection quality at welding places.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

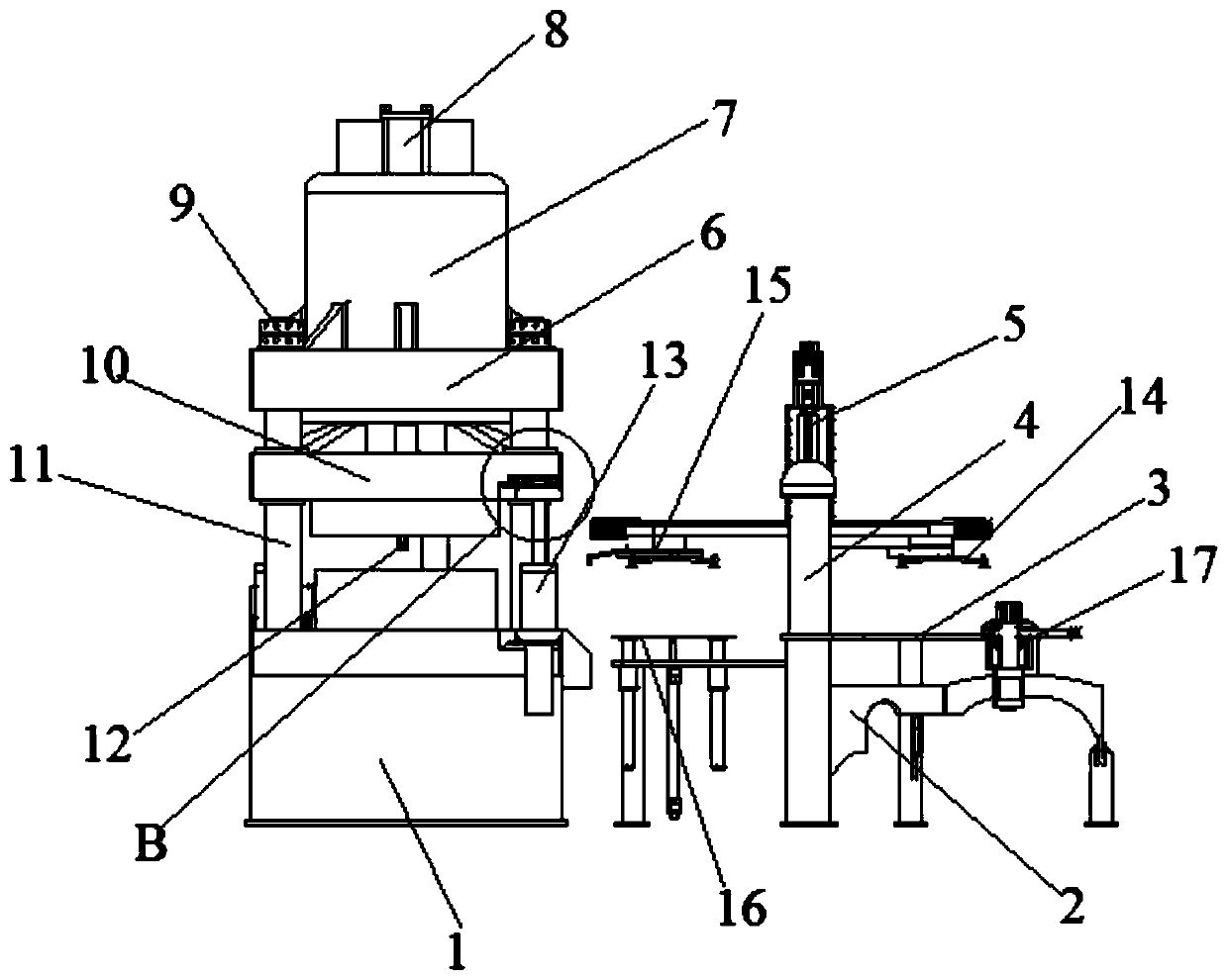

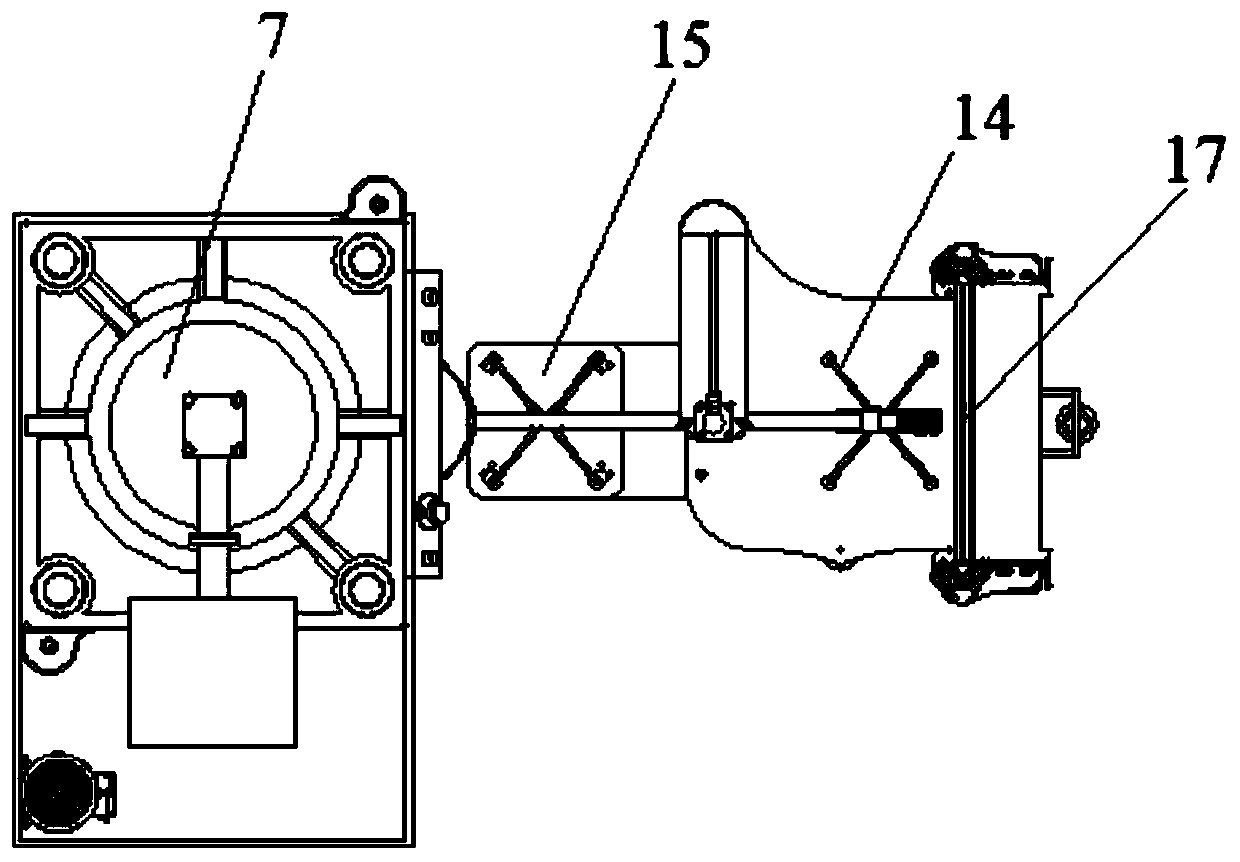

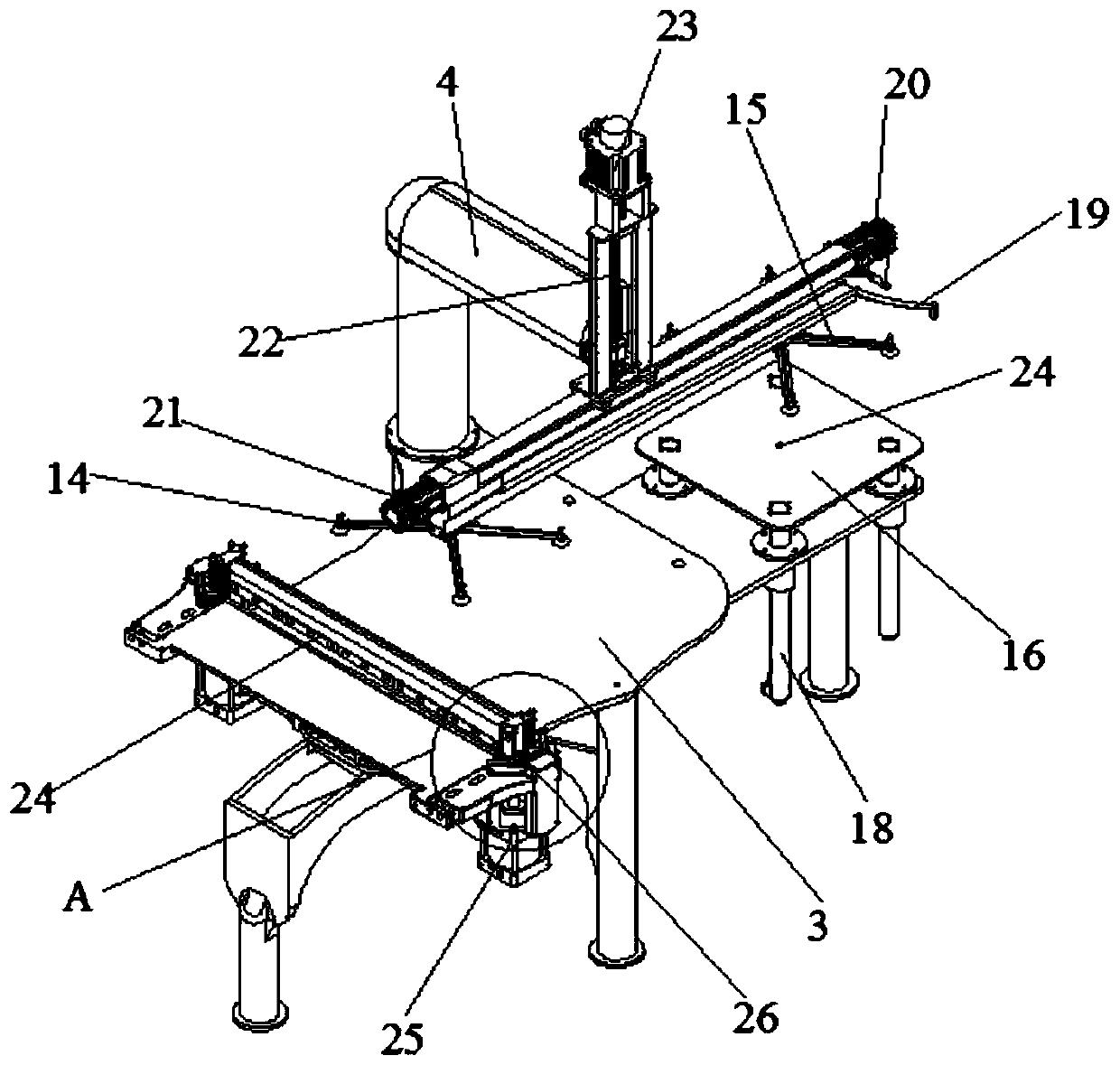

[0026] see Figure 1~6 , in an embodiment of the present invention, a friction stir welding device for 2219 aluminum alloy plates, which includes a support and conveying mechanism 2, a precision lifting adjustment mechanism 16, a friction stir welding mechanism, a welding machine 1 and a feed control mechanism, wherein , the friction stir welding mechanism is provided above the welding machine, and the support and conveying mechanism for supporting and conveying the 2219 aluminum alloy plate is provided on one side of the welding machine, characterized in that, The feed control mechanism for controlling the forward feeding of the 2219 aluminum alloy plate is arranged above the support and conveying mechanism 2, and the feed control mechanism can drive and control the forward speed of the 2219 aluminum alloy plate during welding;

[0027] The precision lifting adjustment mechanism 16 is also provided between the support and conveying mechanism 2 and the welding machine, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com