Precise stroke adjusting device

A stroke adjustment and precision technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of inability to realize precise adjustment of forming machines, subject to subjective factors, and large stroke adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

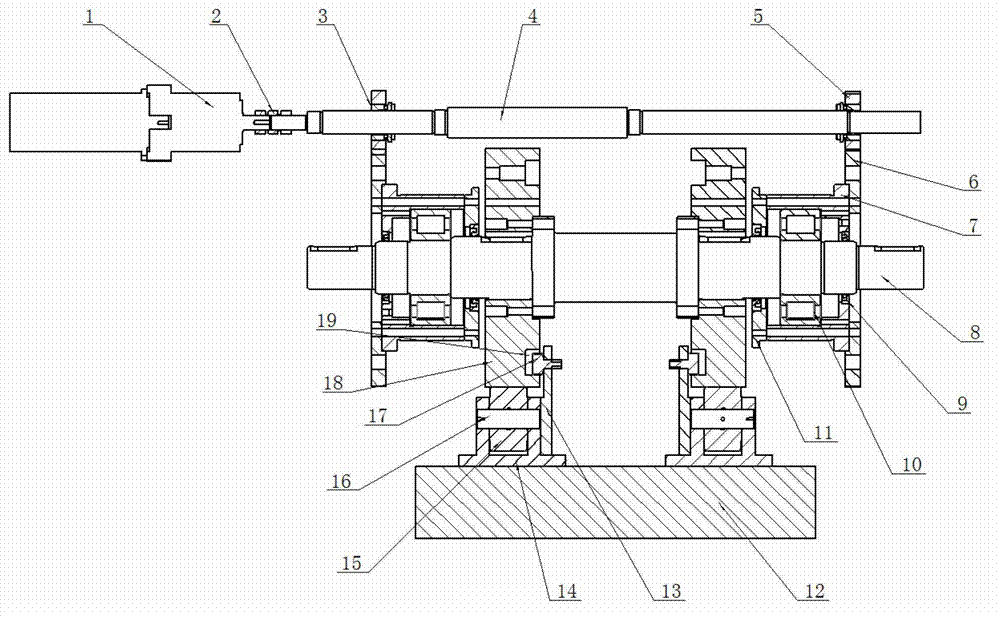

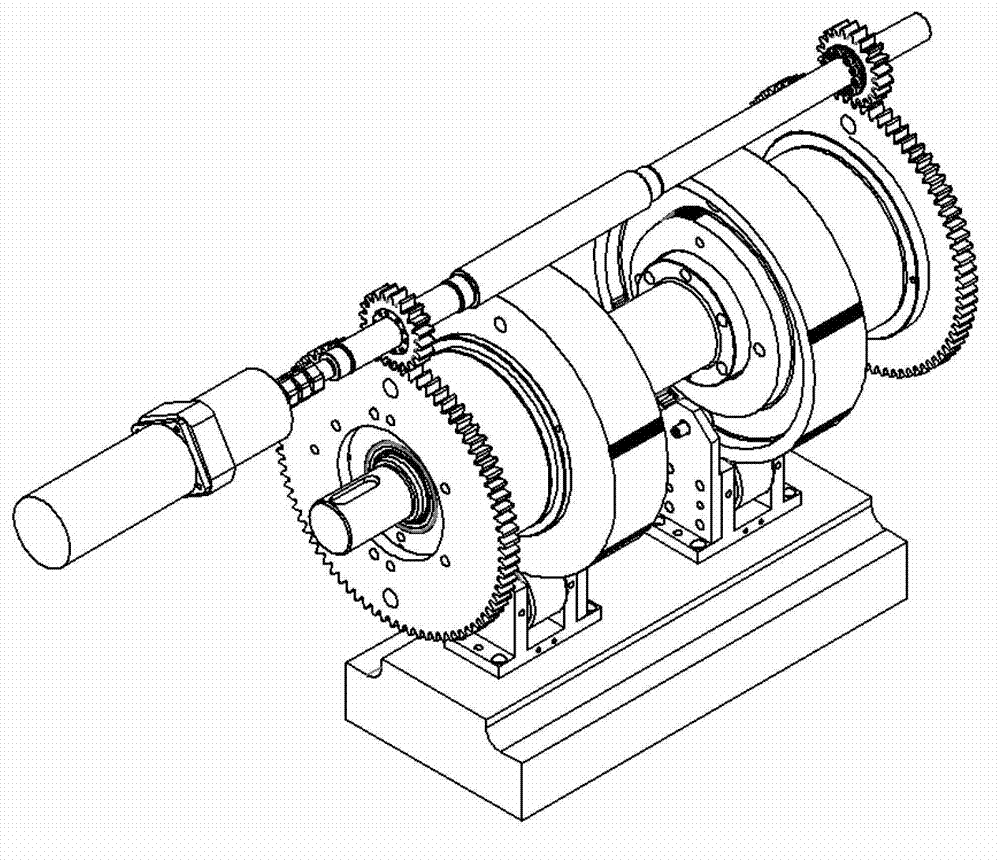

[0015] The precise stroke adjustment device of the present invention, its preferred embodiment is:

[0016] Including pinion shaft system, upper shaft system and roller slider system;

[0017] The pinion shaft system includes a servo motor and a pinion shaft connected to each other, and a pinion is fixed on the pinion shaft;

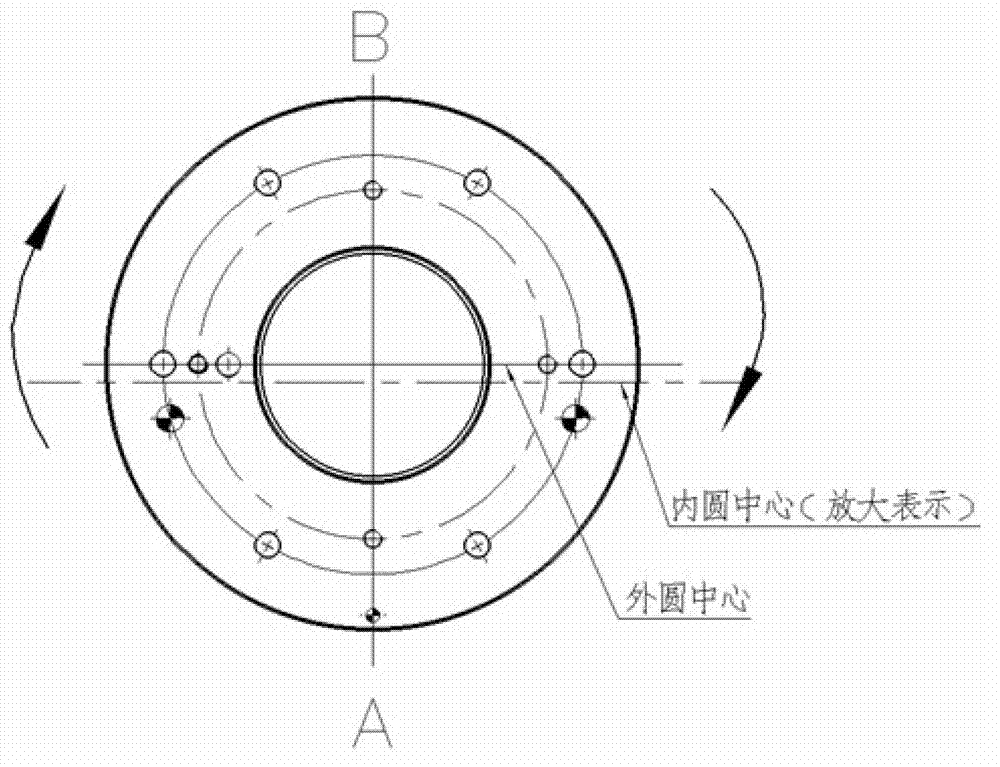

[0018] The upper shaft system includes an upper shaft, on which a cam is fixed, and an eccentric sleeve is installed through a bearing. The eccentric sleeve is fixed with a bull gear, and the bull gear meshes with the pinion gear. The end face is provided with an annular groove;

[0019] The roller slider system includes an upper mold slider, a roller bracket is fixed on the upper mold slider, a sheave bracket is fixed on the roller bracket, a roller is installed on the roller bracket, and a A cam follower, the outer edge of the cam engages with the outer edge of the roller, the cam follower engages with the annular groove.

[0020] An eccentric sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com