Large space to carry the limit device for product disassembly

A technology with a limit device and a large space, which is applied in the directions of transportation and packaging, space navigation equipment, and space navigation vehicles, etc., to achieve the effect of satisfying verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with embodiment.

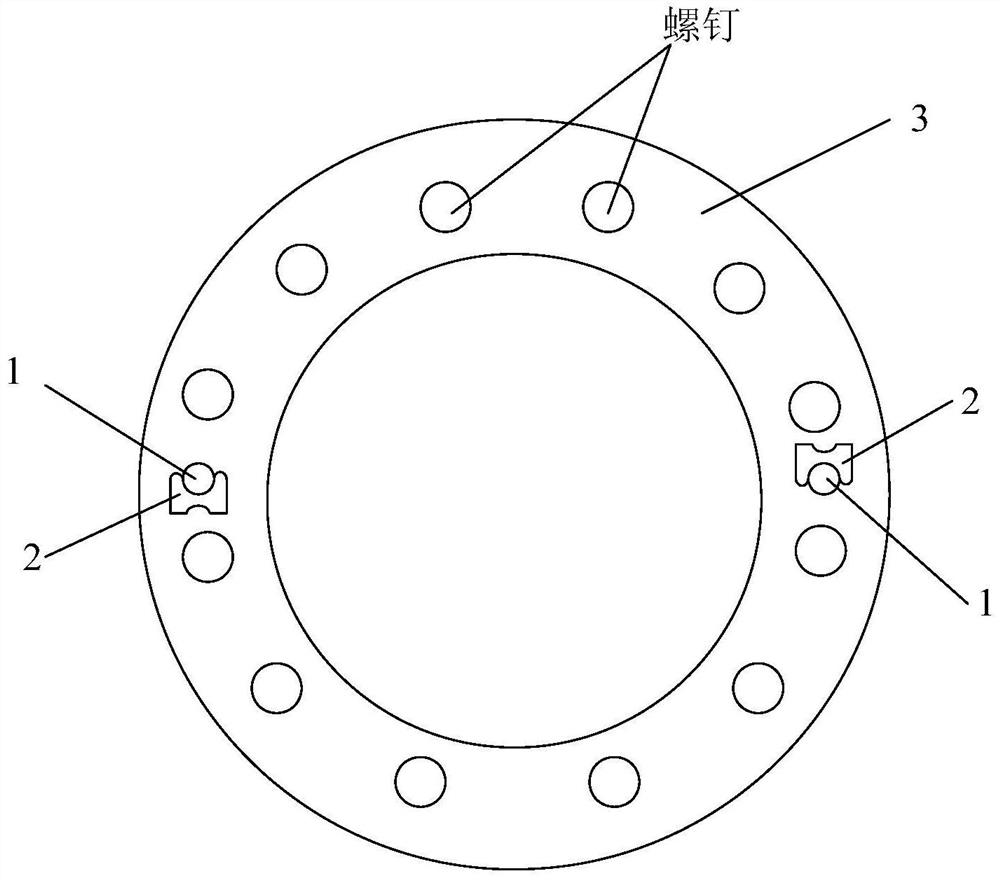

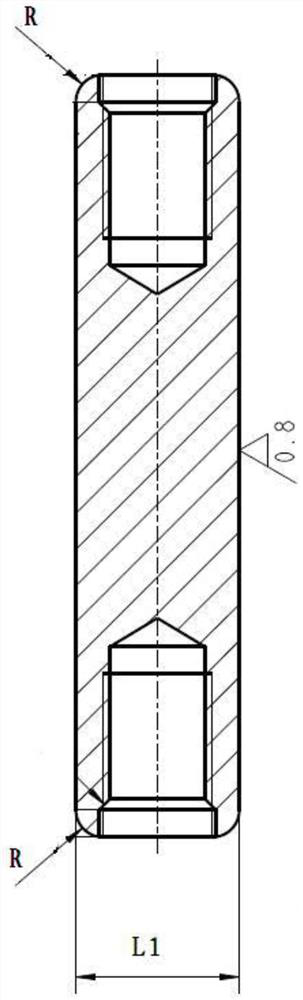

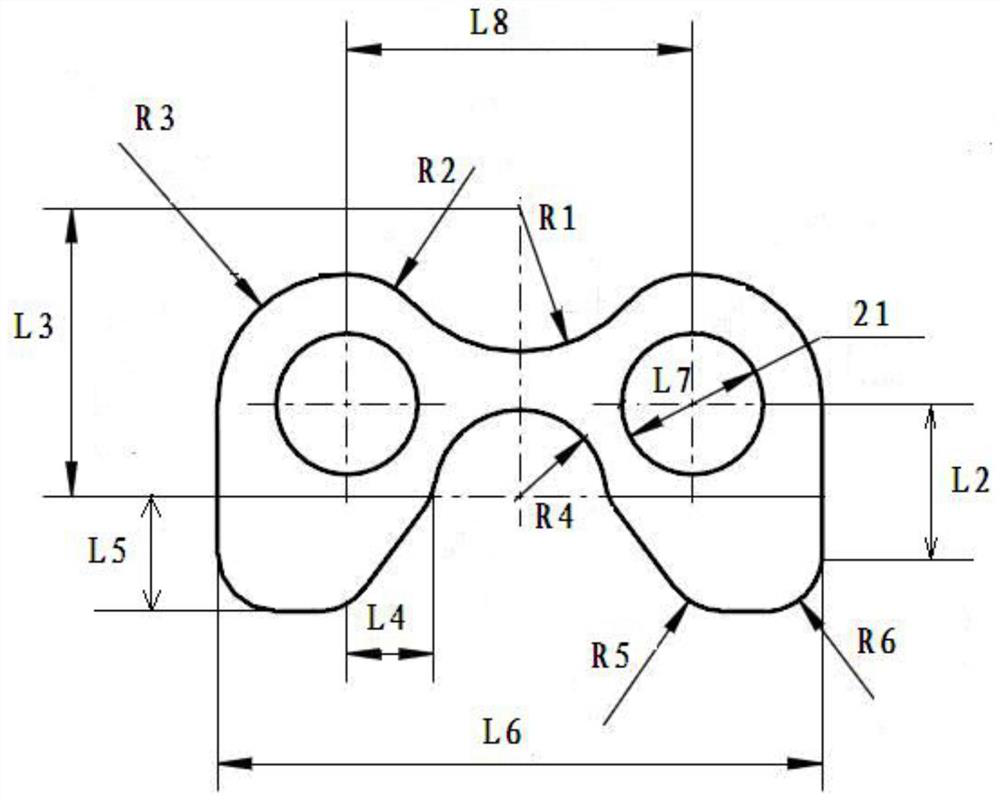

[0025] The key structure of the on-rail dismounting and limiting method for large-space load-carrying products of the present invention lies in positioning pins and limiting blocks. in, figure 1 Shown is the overall schematic diagram of the limit device. It can be seen from the figure that one M4 process screw hole is designed in the center of the end face of the positioning pin 1 for the installation and disassembly of the positioning pin 1. The positioning pin is fixed on the cabin flange 3; the positioning pin 1. There must be enough length to limit the position, and cooperate with the cabin flange 3 and the limit block 2 to limit the position and prevent the axial movement of the mechanical arm. The space is large and the limiting device for product disassembly includes a cabin flange 3, two positioning pins 1 and two limiting blocks 2; among them, the cabin flange 3 is a disc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com