Output type multi-bearing-point independent suspension

A technology of independent suspension and frame, applied in the direction of suspension, elastic suspension, cantilever installed on the pivot, etc., can solve the problems of no change innovation, limited space of bearing points, frequent load changes, etc., to achieve space Take advantage of the effects of optimization, reduced vehicle height, increased number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

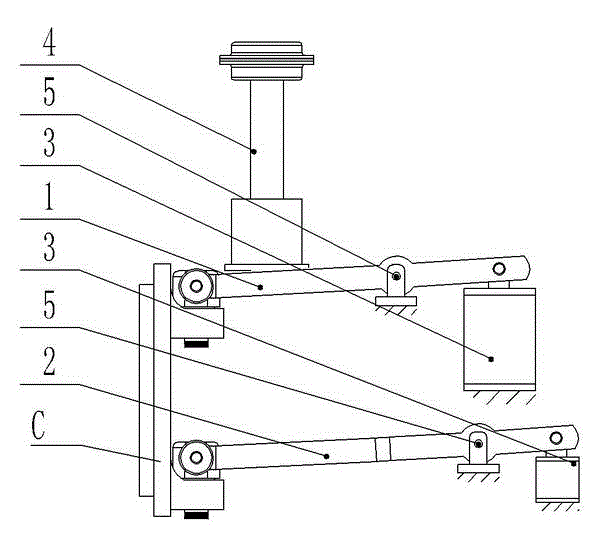

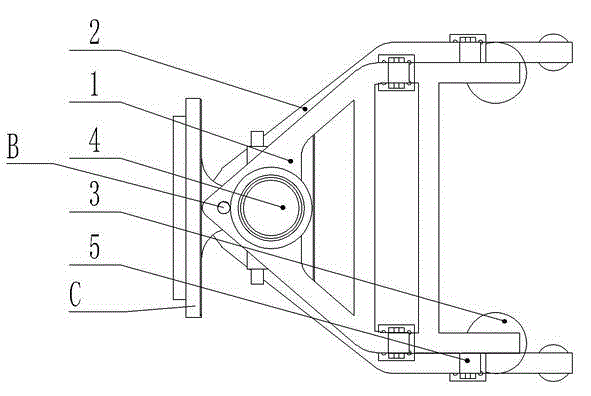

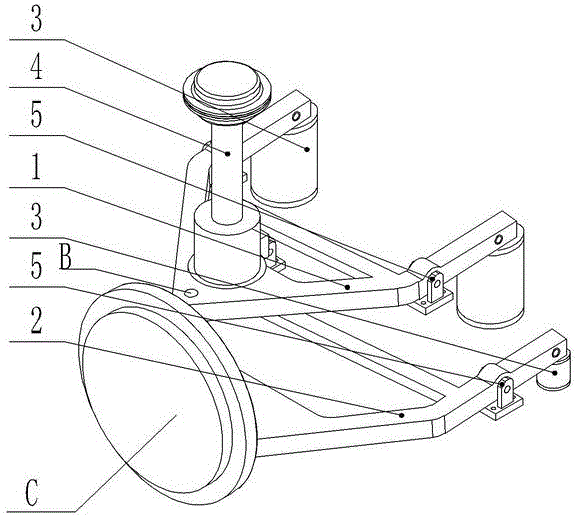

[0046] The cover implementation is the folding back method of the wishbone positioning shaft, please refer to figure 1 , figure 2 with image 3 As shown,

[0047] This embodiment is composed of an upper fork arm 1, a lower fork arm 2, an elastic element 3, a shock absorber 4, and a fork arm positioning shaft 5; the upper fork arm 1 and the lower fork arm 2 are A-shaped structural parts, The front ends of the upper fork arm 1 and the lower fork arm 2 are respectively connected to the upper and lower suspension points of the wheel C through the king pin B, and the middle ends of the upper fork arm 1 and the lower fork arm 2 are respectively connected to the vehicle through the fork arm positioning shaft 5 On the frame, an elastic element 3 is arranged between the bottom of the rear end of the upper fork arm 1 and the frame, and a shock absorber 4 is installed on the upper part of the front end of the upper fork arm 1;

[0048] An elastic element 3 may also be provided between the bo...

Embodiment approach 2

[0052] This implementation is the way of wishbone positioning shaft torsion bar, please refer to Figure 5 , Image 6 , Figure 7 with Figure 8 As shown,

[0053] This embodiment is composed of an upper wishbone 1, a lower wishbone 2, a wishbone positioning shaft 5, a torsion bar 6, a shock absorber 4, and a torsion bar seat 7. The upper wishbone 1 and the lower wishbone 2 are A-shaped structural part, the front ends of the upper and lower wishbone 1 and 2 are respectively connected to the upper and lower hanging points of the wheel C through the kingpin B, and the rear ends of the upper and lower wishbone 1 and 2 are connected through a torsion bar 6 and the torsion bar base 7 are connected to the frame, and a shock absorber 4 is installed between the upper front end of the upper fork arm 1 and the frame.

[0054] The wheel C bounces up and down to drive the front end of the upper fork arm 1 to move upwards, and rotate along the fixed point behind, so that the two torsion bars 6 ...

Embodiment approach 3

[0056] This implementation is a leverage derivation method, please refer to Picture 9 , Picture 10 with Picture 11 As shown,

[0057] This embodiment is composed of an upper fork arm 1, a lower fork arm 2, a fork arm positioning shaft 5, a connecting rod 8, a lead-out lever shaft 9, a lead-out lever 10, an elastic element 3, and a shock absorber 4. Arm 1 and lower wishbone 2 are A-shaped structural parts. The front ends of upper wishbone 1 and lower wishbone 2 are respectively connected to the upper and lower hanging points of wheel C through kingpin B, upper wishbone 1 and lower fork The rear end of the arm 2 is respectively connected to the frame through the fork arm positioning shaft 5, the front bottom surface of the upper fork arm 1 extends two fork arm hanging shafts 81, and the lower end of each fork arm hanging shaft 81 is connected to the leading lever 10 through the connecting rod 8 to lead out The middle end of the lever 10 is articulated with the frame through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com