Loading guiding mechanism for injection mold

A technology of guide mechanism and injection mold, applied in the field of bearing guide mechanism, to achieve the effect of simple disassembly and installation, avoiding enlargement of size and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

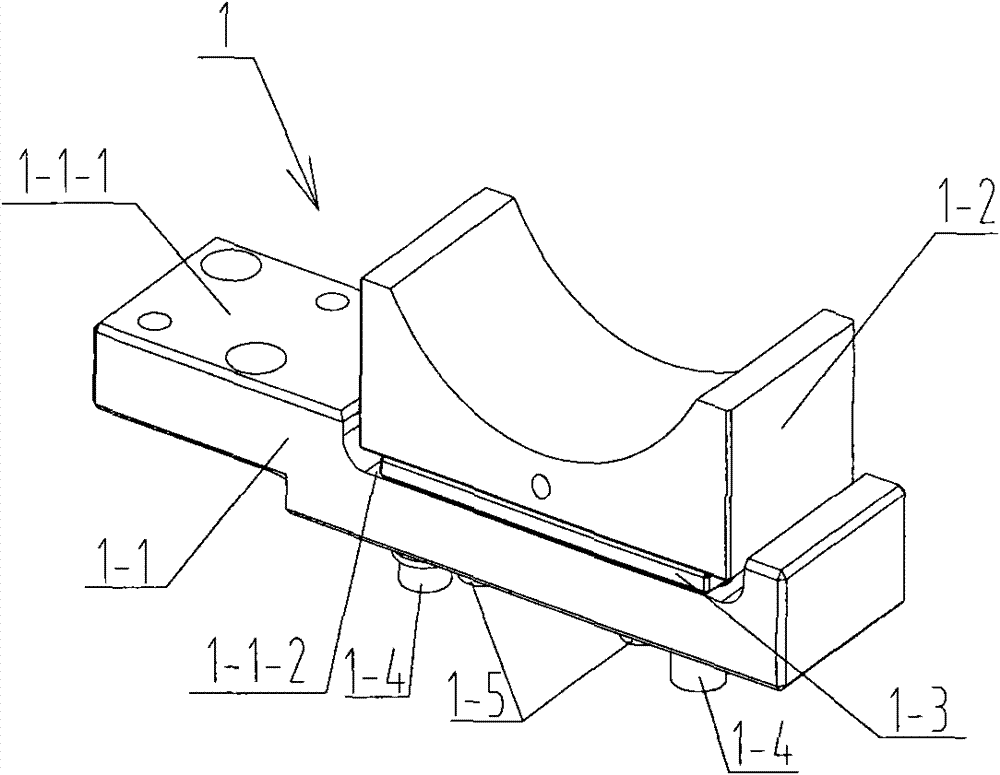

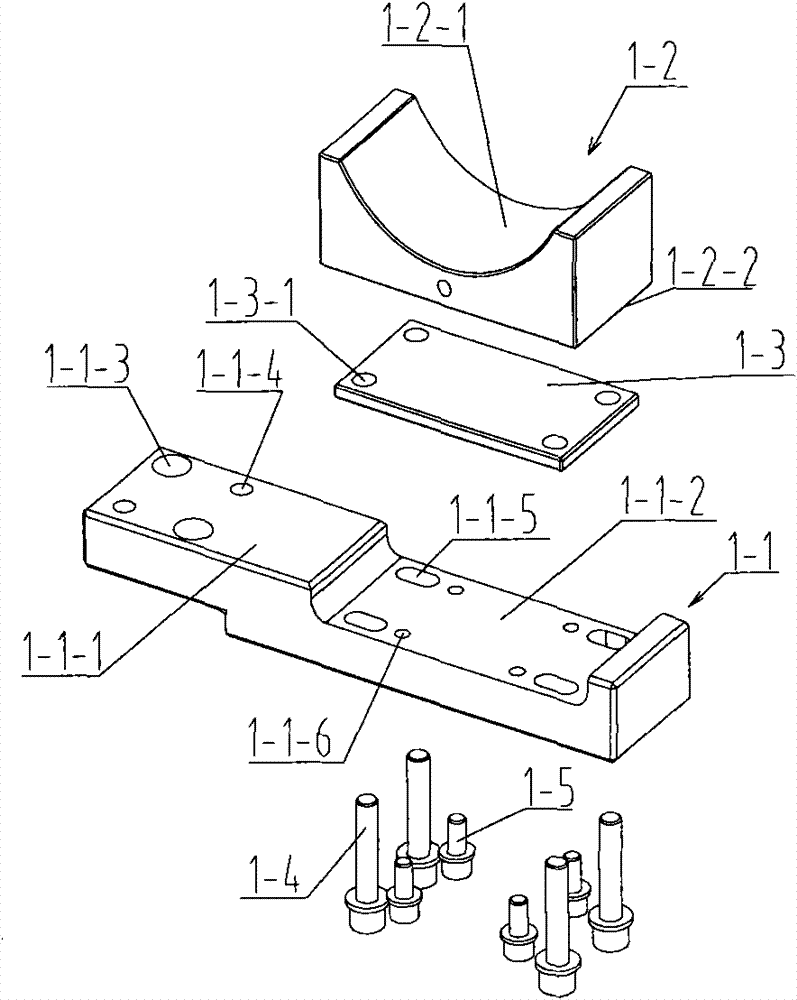

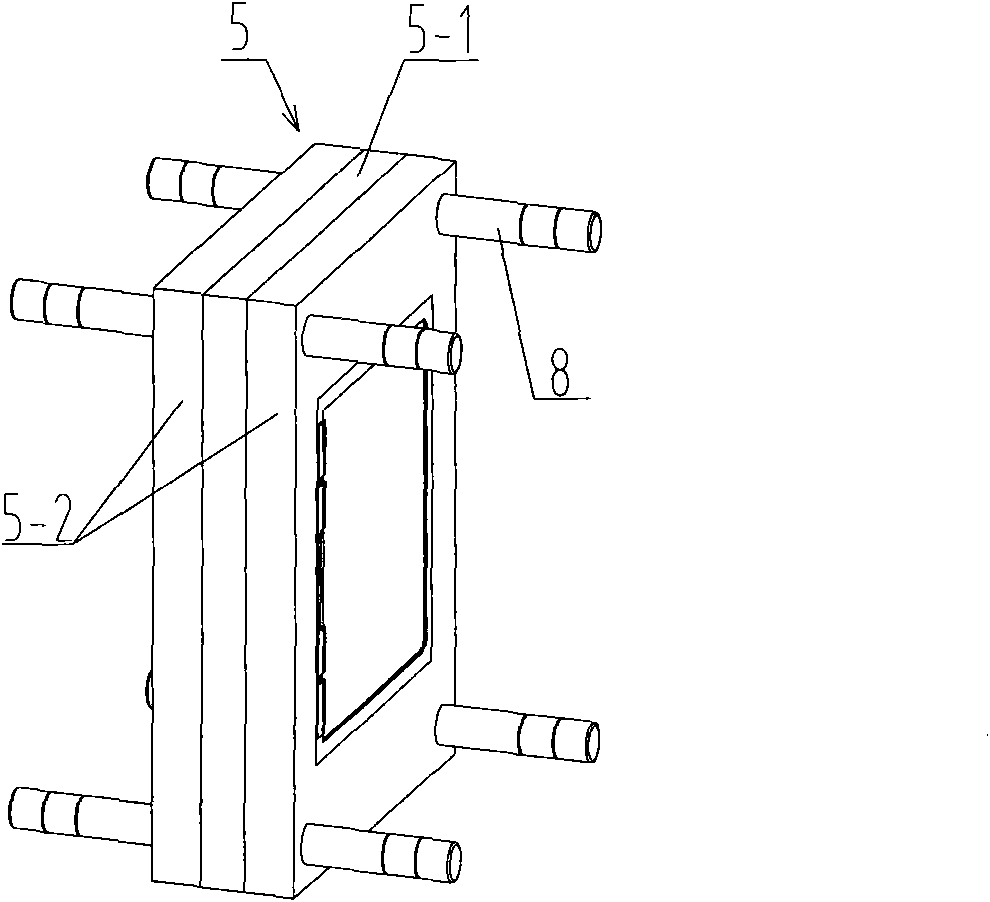

[0026] see figure 1 and figure 2 and Figure 5 1, the bearing guide mechanism 1 includes a bearing plate 1-1, a guide slider 1-2, a pull rod 4, and also includes a bearing adjustment plate 1-3. The bearing plate 1-1 is stepped, including a bearing part 1-1-1 and a guide part 1-1-2, the bearing part 1-1-1 is located at the high surface of the bearing plate 1-1, and the guide part 1-1-1 2 is located at the lower surface of the carrying plate 1-1. Wherein, a through hole 1-1-5 is opened on the guide part, and a screw hole 1-1-3 and a pin hole 1-1-4 are intersected on the bearing part 1-1-1, and the pin 7 passes through the pin hole 1-1-4. 1-4 Position the bearing part 1-1-1 on the middle plate assembly 5, and at the same time, screw II 6 pass through the screw hole 1-1-3 to fasten the bearing part 1-1-1 on the middle plate assembly 5, The intermediate plate assembly 5 is generally composed of three or several templates. In this embodiment, the intermediate plate assembly 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com