Guiding type building workpiece conveying device

A transmission device and guiding technology, which is applied in the direction of buildings, building types, conveyor objects, etc., to achieve a high degree of intelligence, realize the effect of guiding and positioning, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

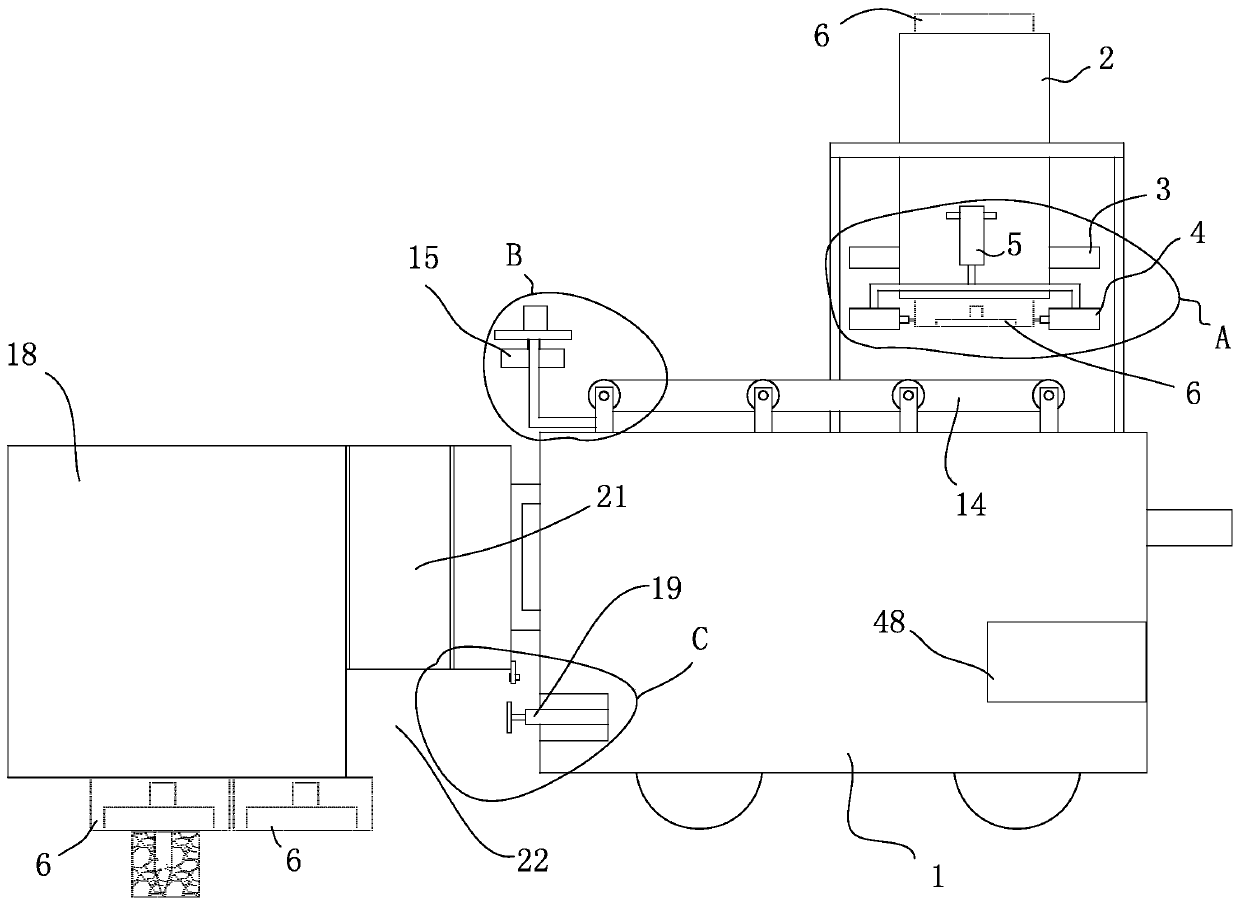

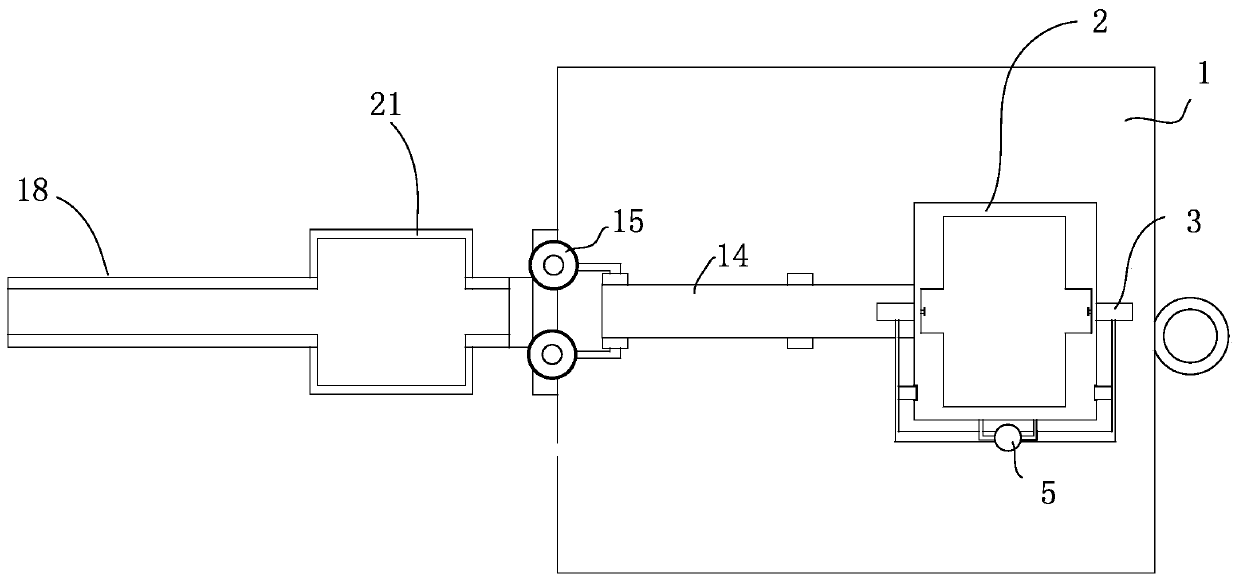

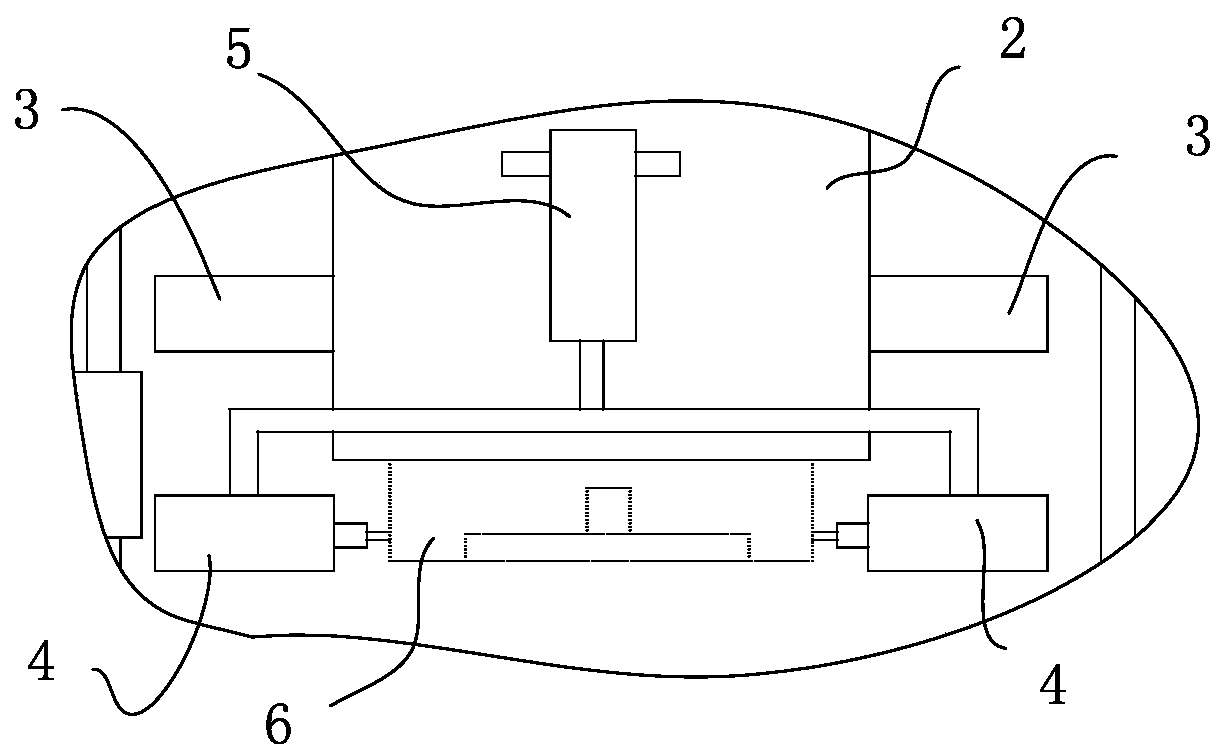

[0028] Such as Figures 1 to 7 As shown, a guided construction workpiece transmission device includes a control system, a walking chassis 1, a shield base placement system, a guard base conveying system, and a guard base guiding system. The power driver of the walking chassis 1 (the bottom is provided with rollers) adopts a stepper motor, or the walking chassis 1 can be driven by an engineering vehicle, or can be driven by manpower; Directional movement, guide rails can be laid, and the walking chassis 1 is set on the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com