Square sheet stamping equipment for hardware

A stamping equipment and square technology, which is applied in the field of square sheet stamping equipment for hardware, can solve problems such as easy cutting of unqualified square iron sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

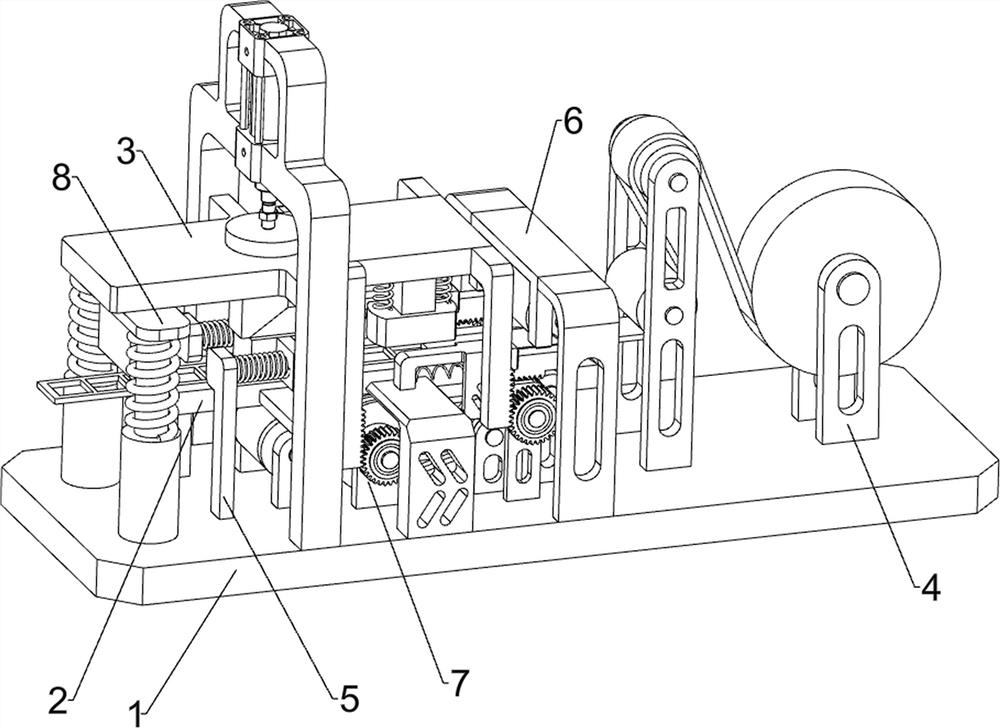

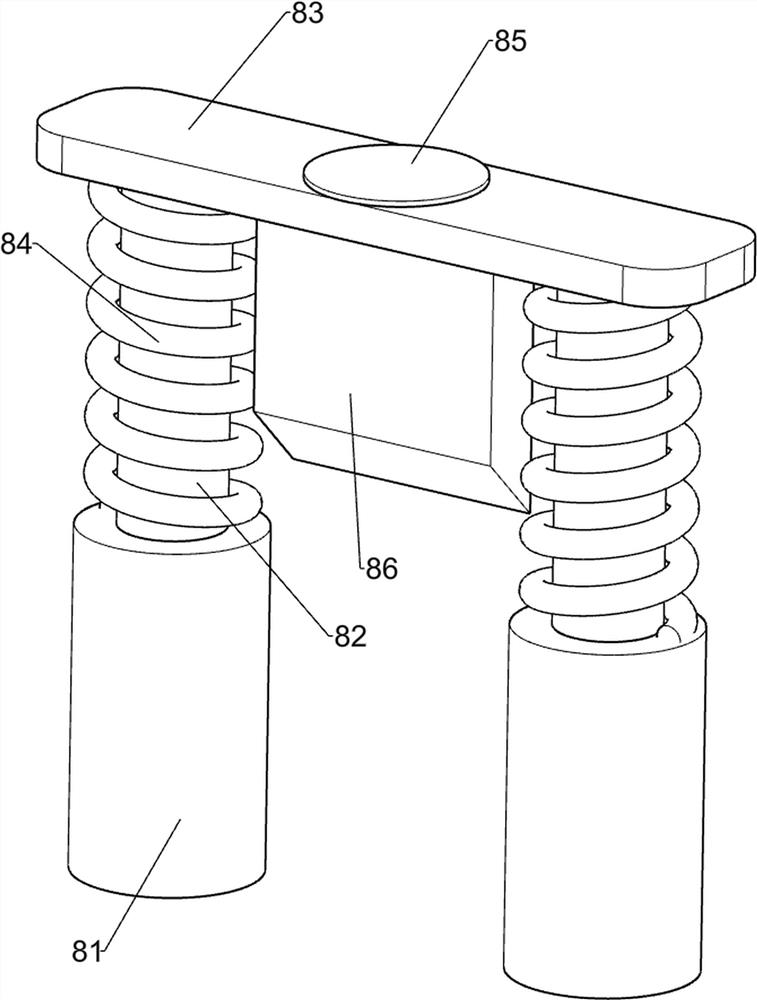

[0029] A square sheet stamping equipment for hardware, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a stamping platform 2, a stamping mechanism 3 and a feeding mechanism 4, a stamping platform 2 is provided on the left side of the top of the bottom plate 1, a stamping mechanism 3 is provided on the left side of the top of the bottom plate 1, and a stamping mechanism 3 is provided on the top right side of the bottom plate 1. Feeding mechanism4.

[0030] When people need to use this equipment, first people will take off the 4 parts of the feeding mechanism, then put the iron sheet roll on the 4 parts of the feeding mechanism, then reset the 4 parts of the feeding mechanism, and bypass the head end of the iron sheet The feeding mechanism 4 moves to the stamping platform 2 below the stamping mechanism 3, and then people can start the stamping mechanism 3. First, the stamping mechanism 3 moves downward, and when the stamping mechanism 3 moves ...

Embodiment 2

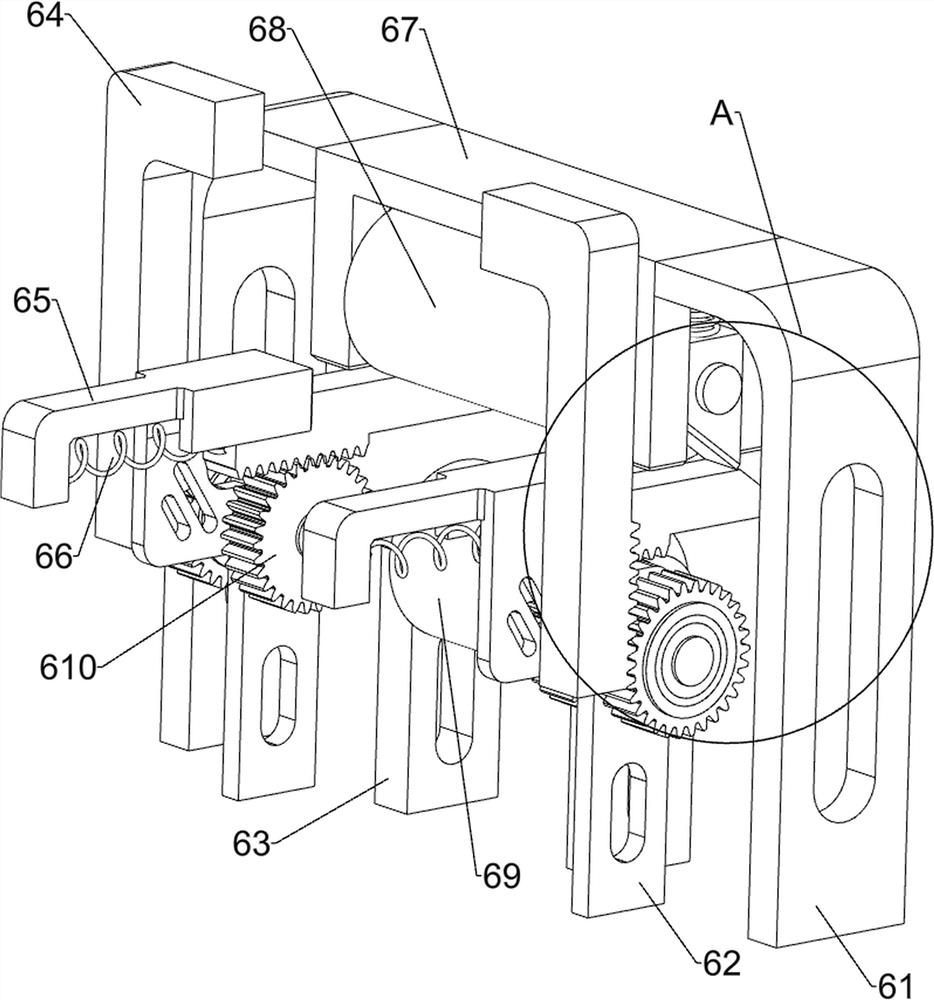

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, it also includes a pulling mechanism 5, and the pulling mechanism 5 includes a pulling support frame 51, a guide post spring 52, a pulling guide post 53, an opening slider 54, a slotting slider 55, and a first wedge block 56 , the second wedge-shaped block 57, the pulling material spring 58 and the pulling material wedge-shaped block 59, the left side of the bottom plate 1 top is symmetrically provided with a pulling material support frame 51, and the pulling material support frame 51 is equipped with a guide post spring 52, and the pulling material support frame 51 is provided with pulling material guide post 53, and guide post spring 52 is enclosed within pulling material guide post 53 outsides, and drawing material guide post 53 is all slidingly provided with perforated slide block 54, and perforated slide block 54 is provided with Slotted slider 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com