Brick discharging system of automatic production line of brick making machine

A technology of automatic production line and brick making machine, which is applied in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of easy personal injury, excessive production of defective products, inevitable bumps, etc. The effect of personal injury incidents, less labor, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

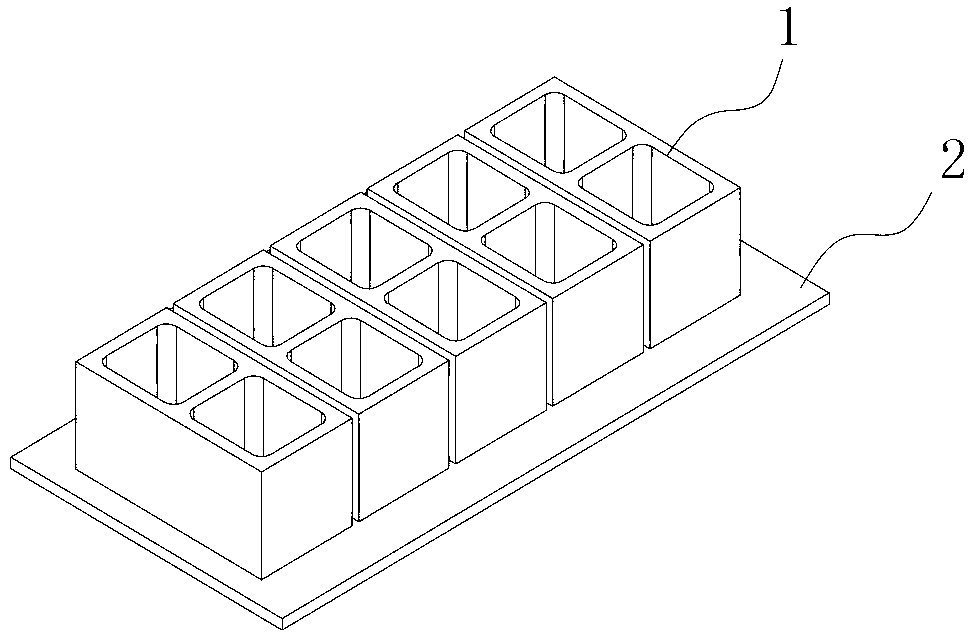

[0024] figure 1 It shows the state of unburned bricks 1 coming out of the discharge part of the brick making machine. Multiple unburned bricks 1 are arranged side by side on the backing plate 2, and they remain in this state during transfer and transportation until the unburned bricks 1 are cured. In the prior art, the burn-free bricks 1 and the backing plate 2 are manually transported to the trolley, and then pushed to the maintenance site.

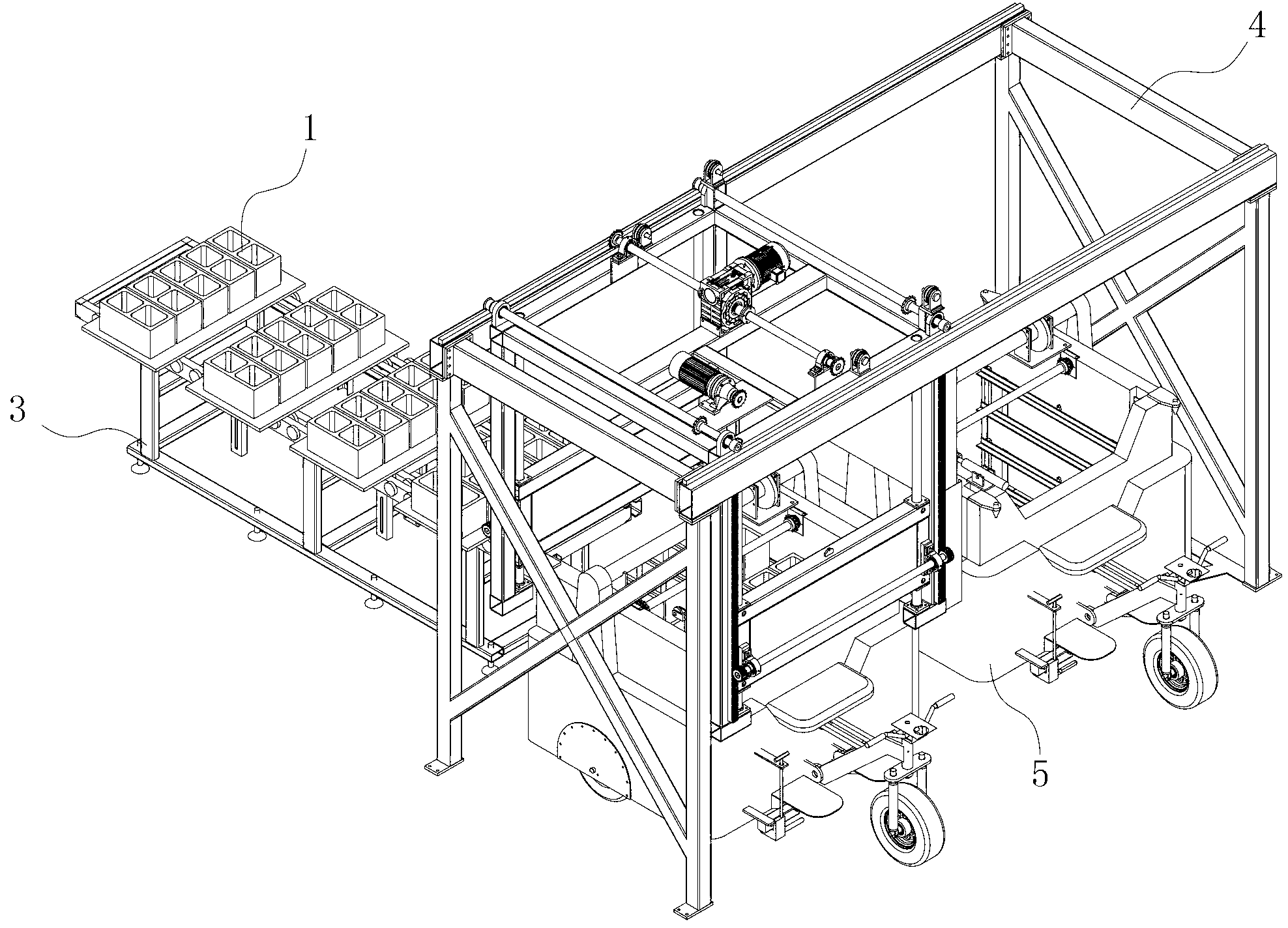

[0025] figure 2 It shows the overall structure of the brick production system. It includes a conveyor frame 3, a feeding frame 4 and a transport vehicle 5, wherein the conveyor frame 3 is connected to the discharge part of the automatic production line of the brick making machine, and is used to feed materials to the feeding frame 4, and the feeding frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com