Full-automatic rubber ointment painting and coating equipment and technique

A technology of rubber paste and coating process, which can be applied to devices and coatings for coating liquid on the surface, which can solve the problems of waste of resources, poor reliability, and low technical content, save production costs, and avoid the handling process and operation. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

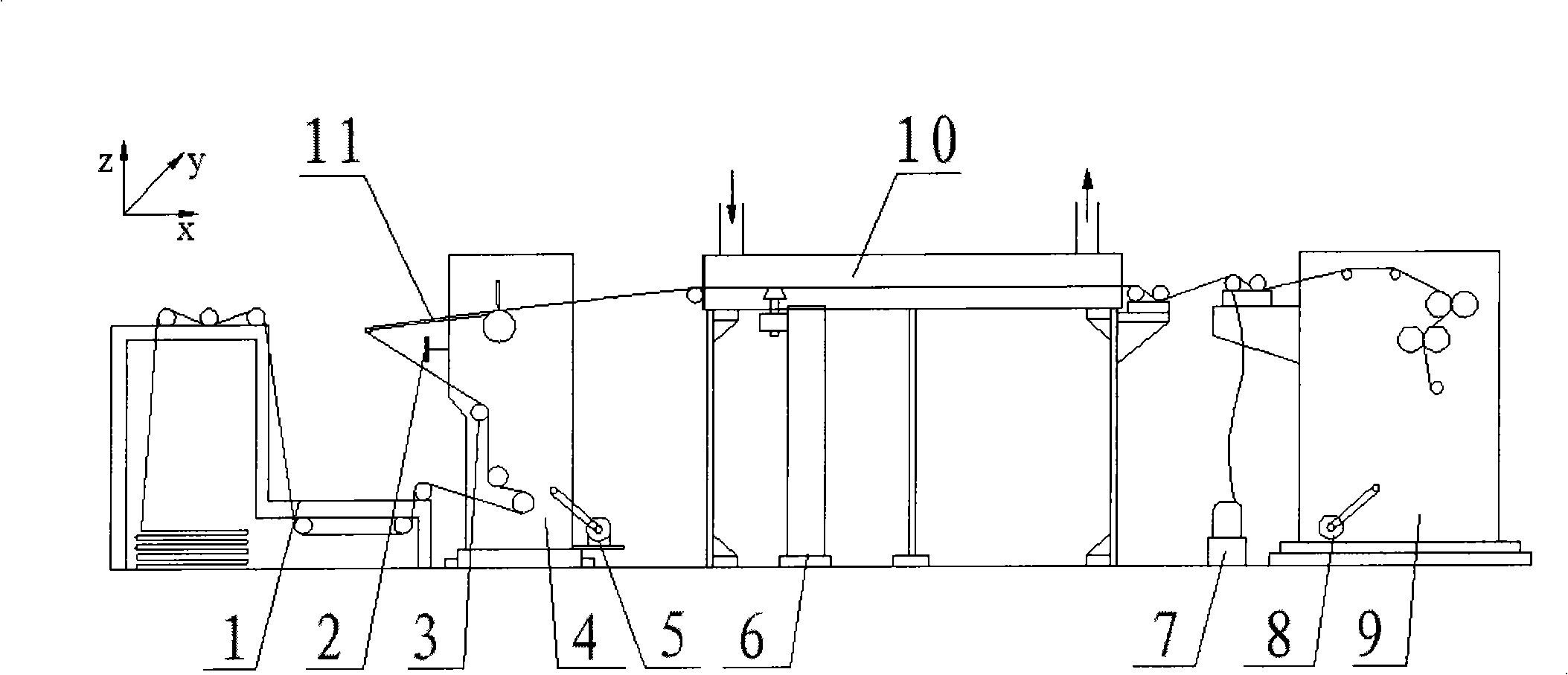

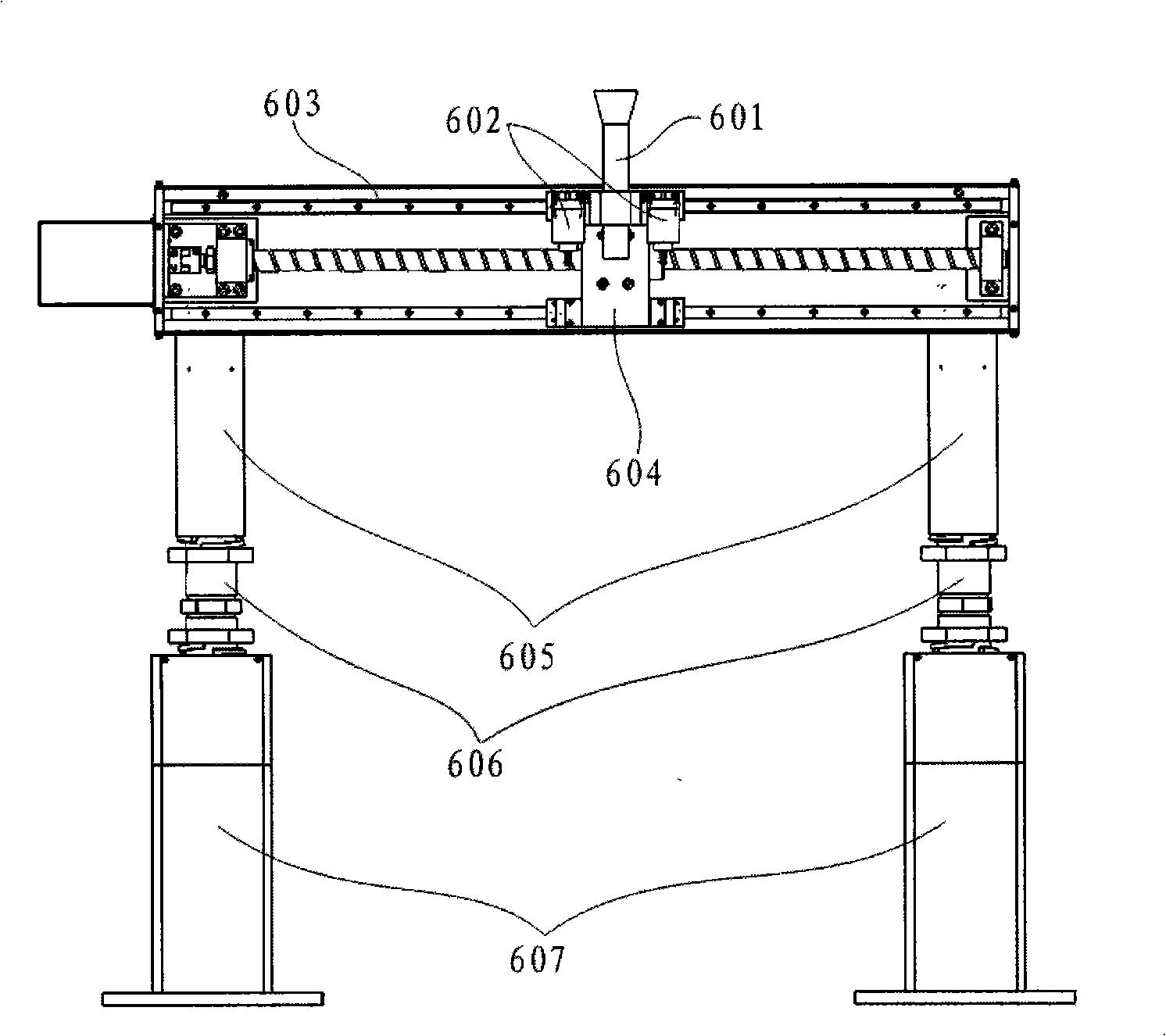

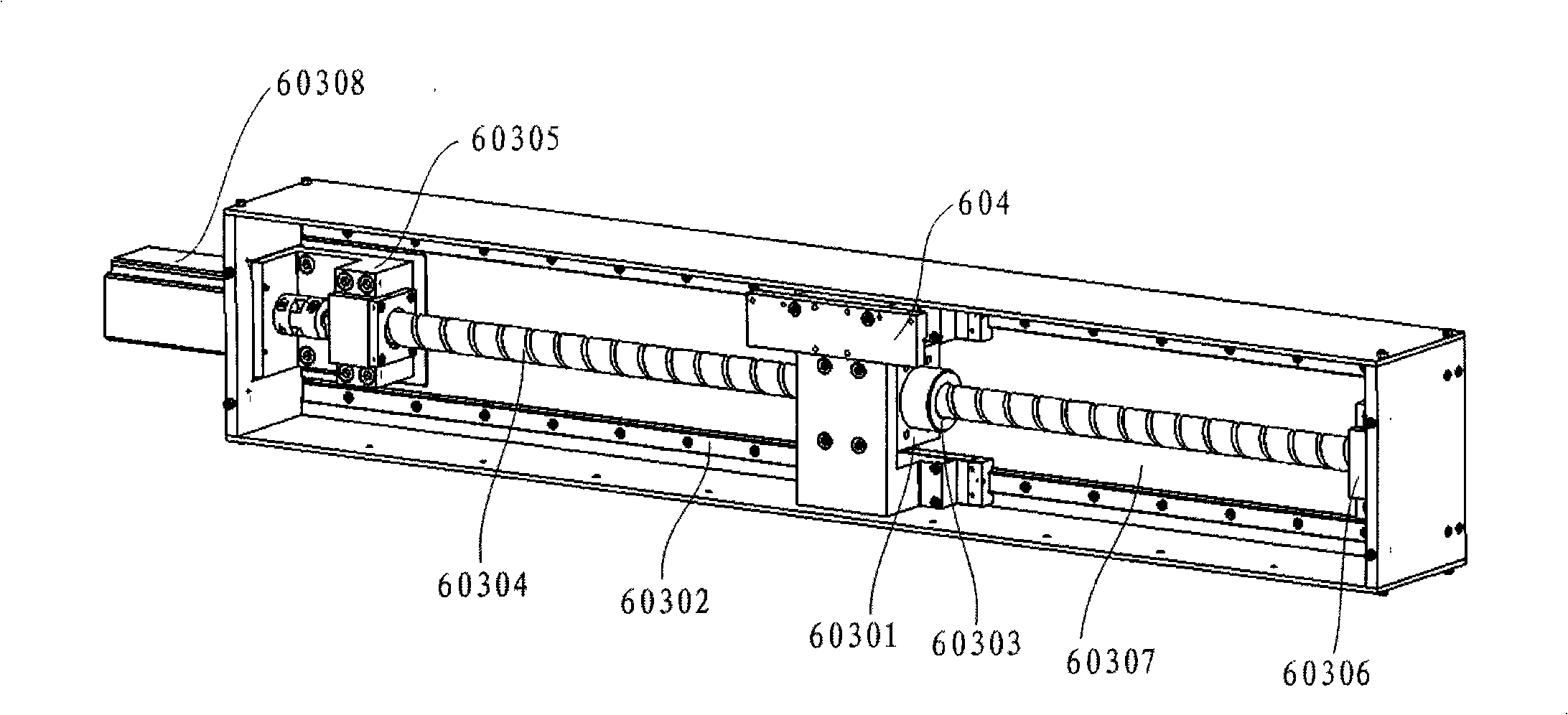

[0033] Such as figure 1 As shown, a fully automatic rubber paste coating equipment includes a cloth feeding mechanism 1 , a vehicle before coating 4 , a cooling box 10 , an automatic detection device for coating thickness 6 and a vehicle 9 after coating. Among them, along the cloth feeding direction, the cloth feeding mechanism 1, the vehicle before coating 4, the cooling box 10 and the vehicle after coating 9 are arranged in sequence, and are connected by a cloth for applying rubber paste; Thickness automatic detection device6. A plurality of support rollers 3 are all installed on the cloth feeding mechanism 1 , the front vehicle 4 before coating, the cooling box 10 and the vehicle 9 after coating. In addition, according to the actual situation, the front car motor 5, the rear car motor 8 and the air source power 7 of the deviation correction device are installed at the parts that need to provide power. The front car motor 5 is used to drive the coating roller 402 of the fro...

Embodiment 2

[0044] figure 1 In the coating front car 4 is Figure 9 Shown is coated front car instead. Such as Figure 9 shown, with Figure 5 The difference between the coating front car is that two digital displays 404 are installed on both sides of the coating front car body, which are respectively used to display the height of the scraper gap on the left and right sides detected by the coating thickness automatic detection device 6; at the same time, Figure 5 The automatic scraper gap adjustment mechanism 401 in the Figure 10 As shown, the device saves the Image 6 In the servo motor 40101, the connection mode of other parts remains unchanged. When adopting this coating front vehicle structure, the adjustment of the scraper gap can only be adjusted by adjusting the hand wheel 2 to drive the rotation of the worm screw 40102.

[0045] According to the change of the vehicle structure before coating, the rubber paste coating process has also changed. Compared with the specific emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com