Method and system for manufacturing metal case

A technology for metal shells and shells, which is applied to metal shells, TV system components, color TV components, etc., can solve problems such as rising product unit costs and low product qualification rates, so as to improve process stability and reduce Unit cost, effect of variable reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The advantages and concepts of the present invention can be further understood through the following detailed description of the present invention in conjunction with the accompanying drawings.

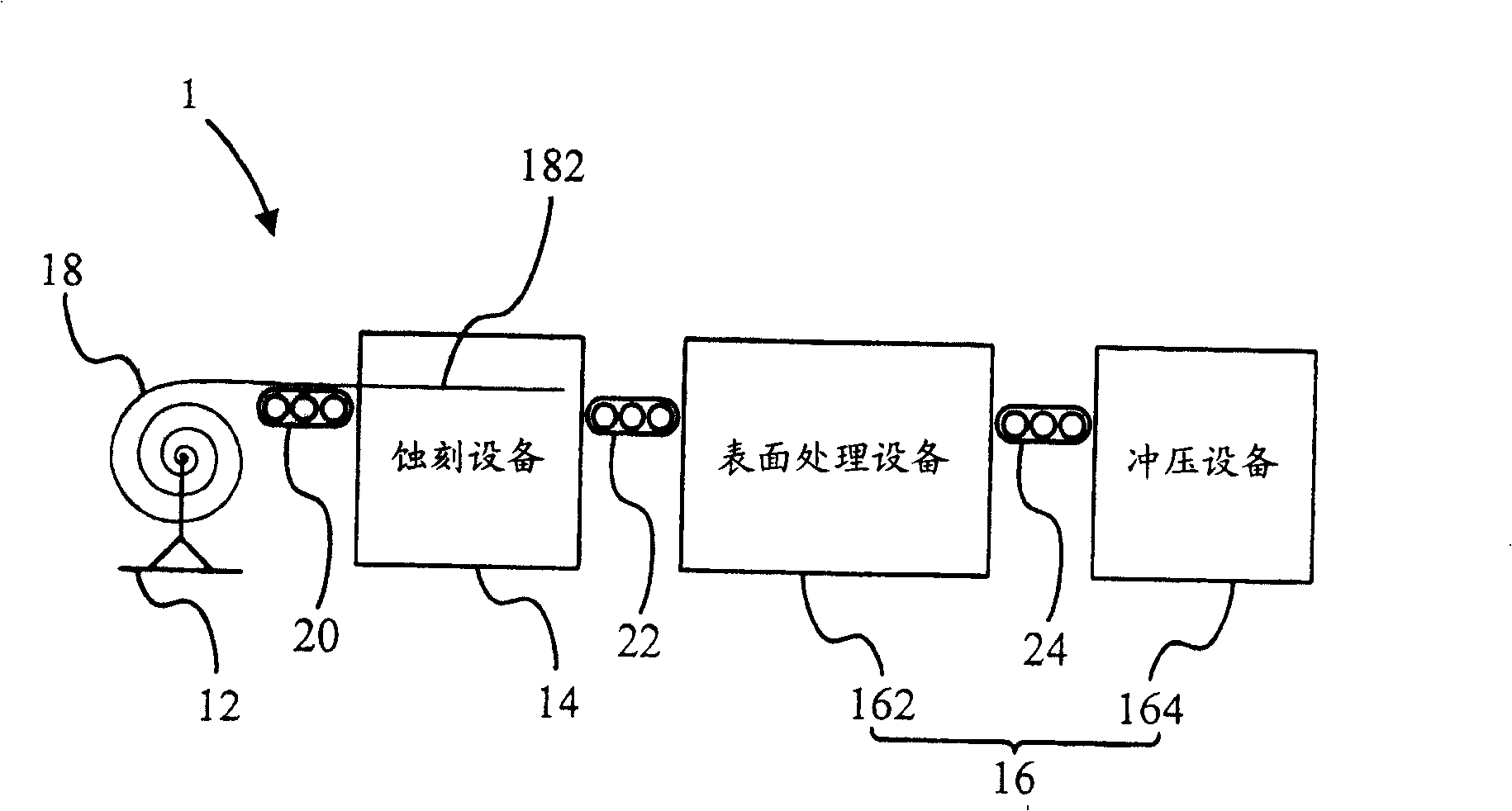

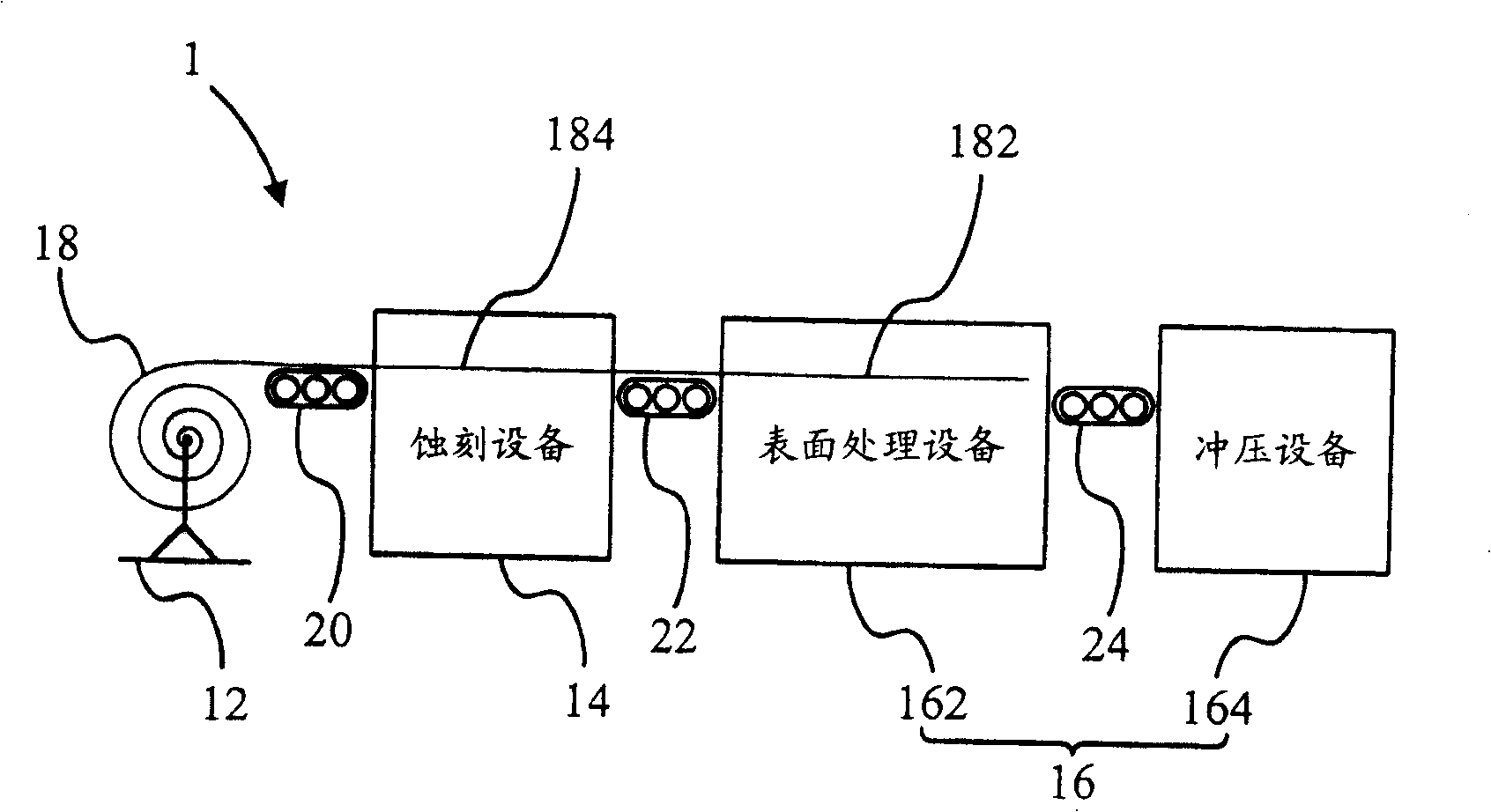

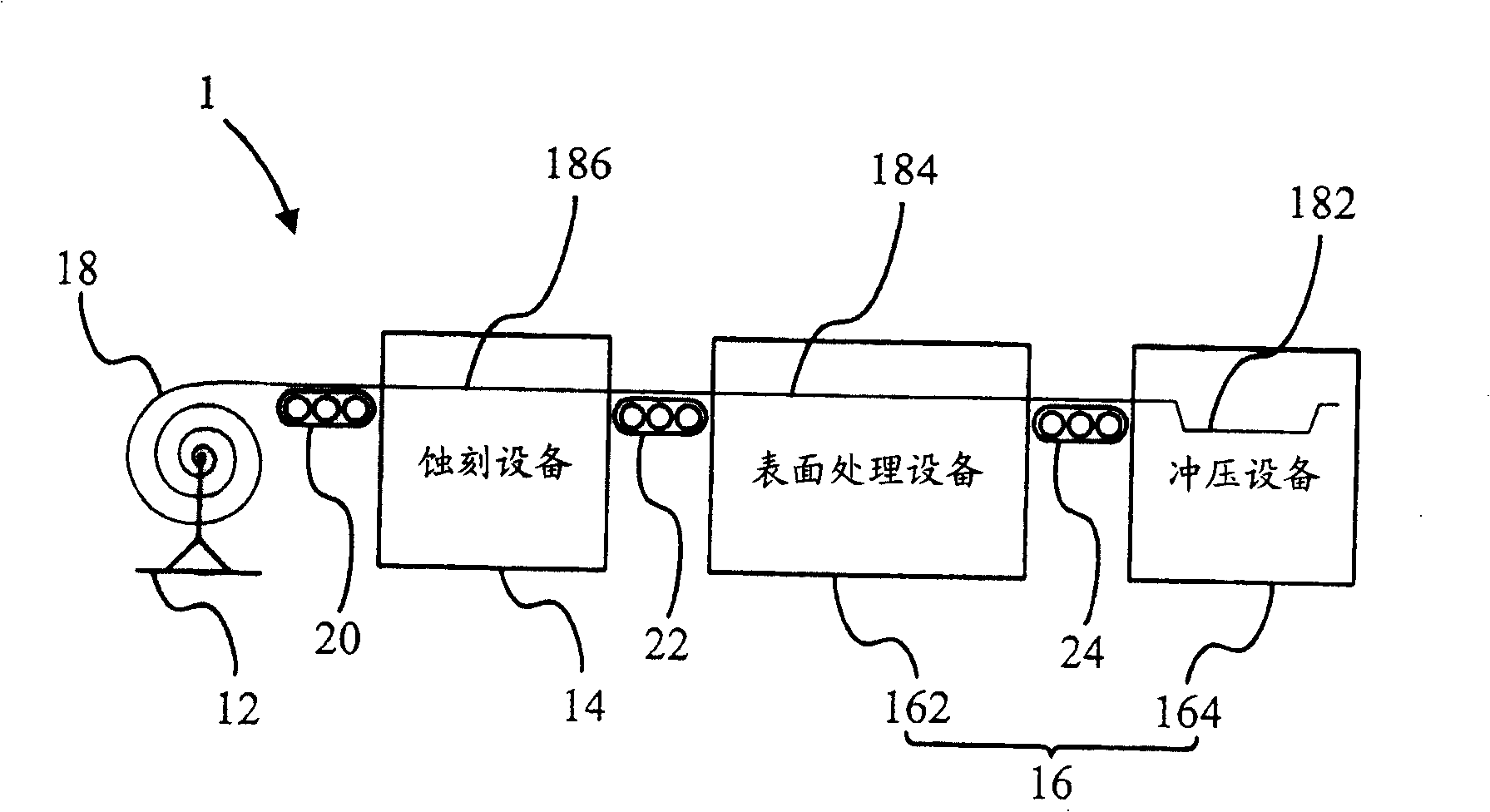

[0029] see Figure 1A to D, Figure 1A to D are schematic diagrams of the system 1 for manufacturing the metal casing 3 according to the first preferred embodiment. According to a first preferred embodiment, the system 1 comprises a feeding device 12 , an etching device 14 and a forming device 16 . Forming equipment 16 includes surface treatment equipment 162 and punching equipment 164 . The feeding device 12 supports a roll of sheet metal 18 and sequentially feeds a portion of sheet metal 182 from the roll of sheet metal 18 . An etching device 14 is connected to the feeding device 12 . Surface treatment equipment 162 is coupled to etching equipment 14 . The stamping device 164 is coupled to the surface treatment device 162 . According to the first preferred embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com