Device for maintaining separate ingredients in liquid food products

a technology for liquid food products and ingredients, applied in the field of liquid food product storage, can solve the problems of not being used with currently sold beverages and liquid mixtures, flavors, oils, vitamins, supplements, etc., and achieve the effects of convenient use, safe storage, and selective dispensing into the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

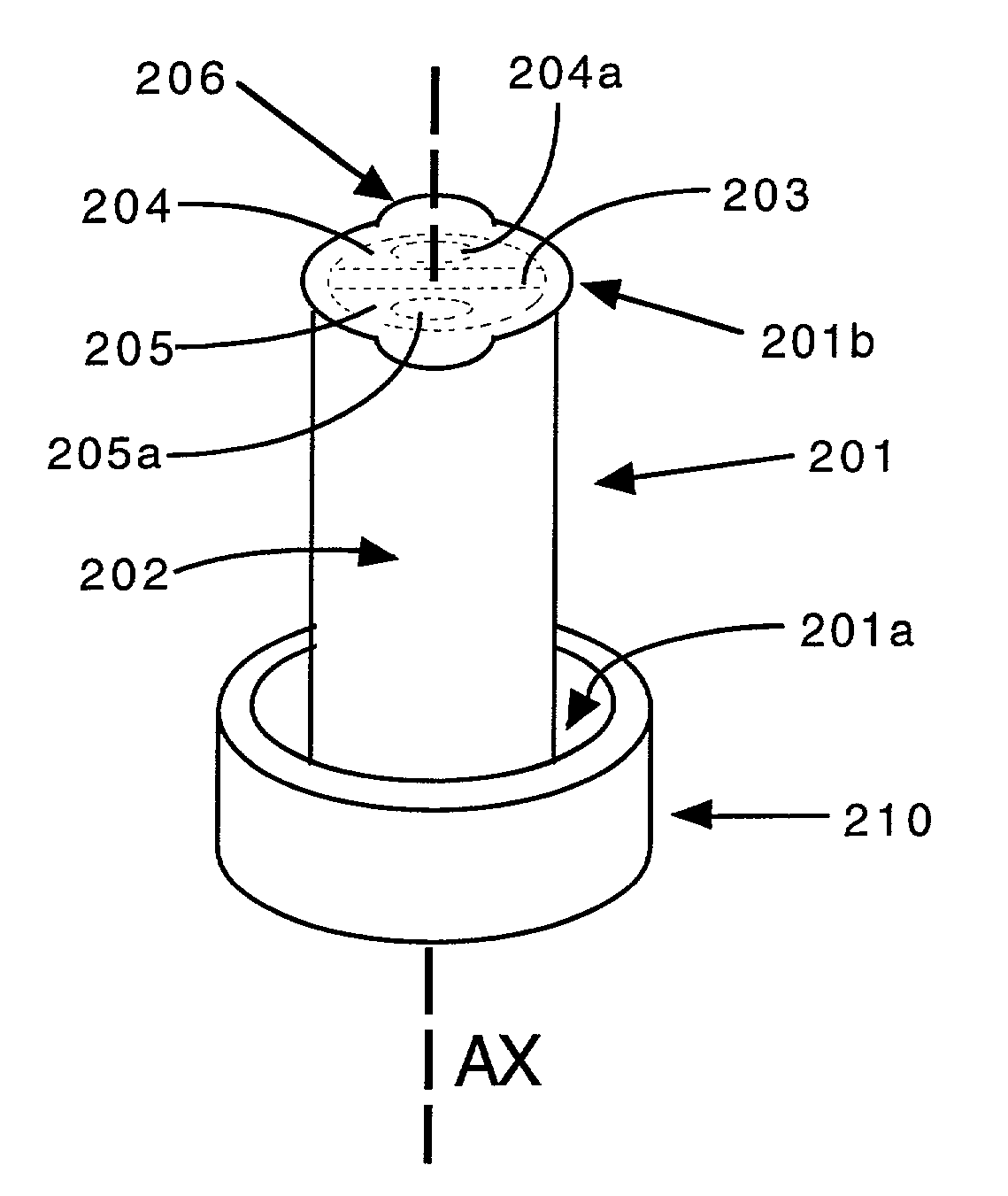

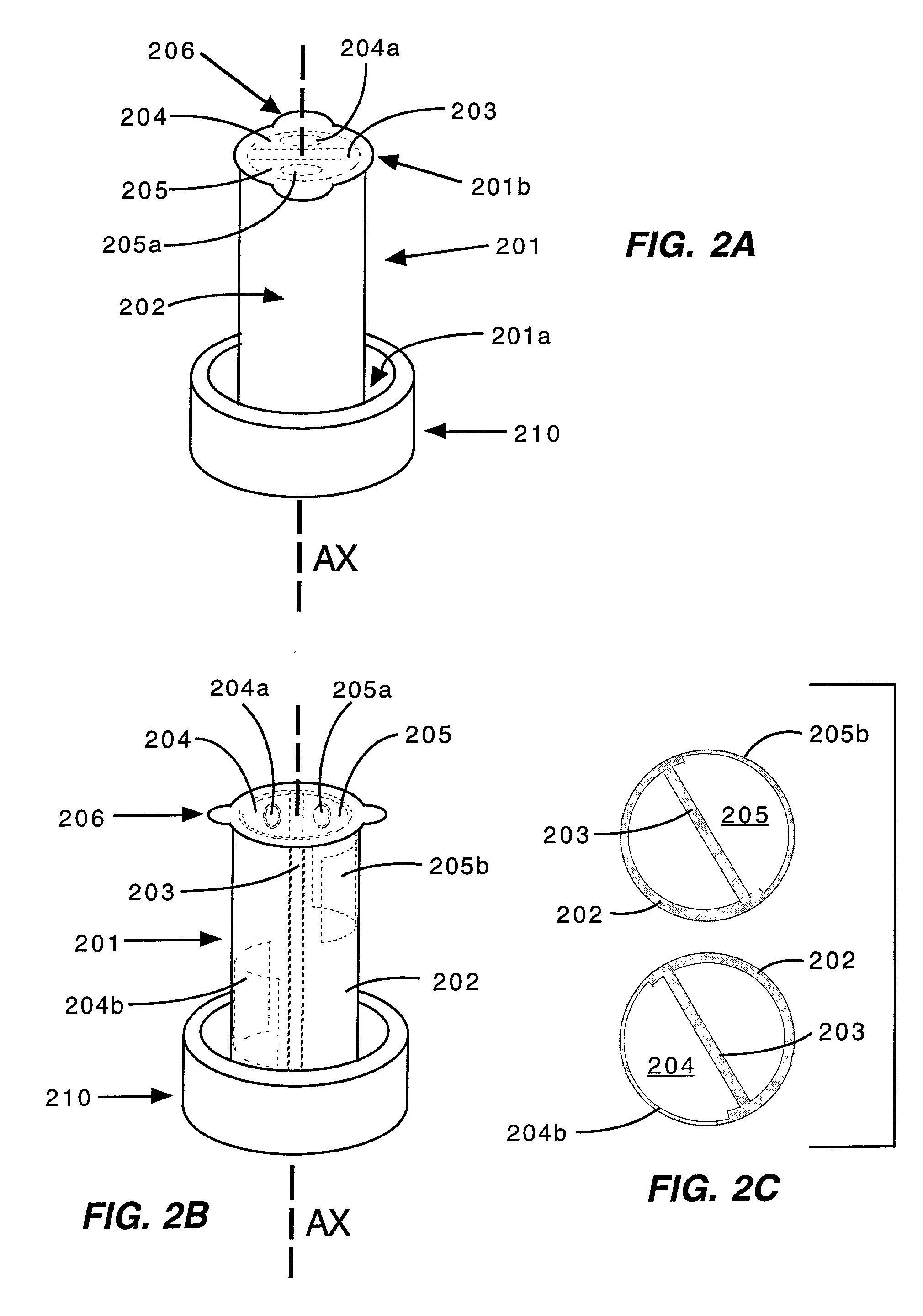

[0042] Referring to FIGS. 2A and 2B, the device for use with a bottle container has a sub-container body 201 in cylindrical form with a proximate end 201a mounted to the underside of the container cap 210. The sub-container body 201 has squeezable plastic outer walls 202 and at least one inner divider wall 203 which is aligned in parallel with a cylinder axis AX of the sub-container body. The divider wall 203 divides the interior of the sub-container body into two axially oriented compartments 204, 205. A greater number of compartments can be formed by using more than one divider wall.

[0043] The compartments 204, 205 are used to contain respective flavorings, oils, vitamins, supplements, medicines, and other ingredients to be mixed in the carrier liquid at the time of use. The compartments have respective dispensing orifices 204a and 205a formed through closure walls at the distal end 201b of the sub-container body. The orifices of the individual compartments are sealed with individ...

second embodiment

[0047] In FIGS. 3A, 3B, and 3C, the device is shown having a cylindrical sub-container body 301 with its proximate end detachably mounted to the underside of the container cap 310 by detent surfaces 307 snap-fitted onto projections 311 on the underside of the cap. The sub-container body 301 has squeezable plastic outer walls 302. The divider wall 303 divides the interior of the sub-container body 301 into compartments 304 and 305. The compartments 304 and 305 have respective dispensing orifices 304a and 305a formed at the proximate end of the sub-container body. As shown in more detail in FIGS. 3D and 3E, the orifices are sealed with removable sealing tabs 304c and 305c, and have anti-drip edges 312. In this embodiment, positioning the compartment orifices at the proximate end keeps them away from the carrier liquid and reduces the possibility of seepage or liquid penetration into the seals.

[0048] In FIGS. 4A, 4B, and 4C, a third embodiment of the device, similar to the first embodi...

fourth embodiment

[0050] In FIGS. 5A, 5B, and 5C, the device is shown having a sub-container body 501 in cylindrical form with its proximate end 501a mounted to the underside of the container cap 510. The sub-container body is formed with squeezable plastic outer walls 502, and has divider walls 503 aligned transverse to the cylinder axis AX dividing the interior of the sub-container body into a plurality of transversely oriented compartments 504, 505, and 506. The compartments have respective orifices 504a, 505a, and 506a formed at predetermined positions of the outer walls for each compartment.

[0051] In FIG. 5D, the sub-container body 501 is shown in greater detail having an indented detent surfaces 507 to which projections 511 on the underside of the cap are snap-fitted to mount the sub-container body to the cap. The portions of the outer walls at the positions of the orifices can be formed with puckers 504d, 505d, and 506d for better directing of ingredients from the orifices under pressure. In F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com