On-line core making technology and device

A core-making device and process technology, applied in the field of online core-making process and device, can solve the problems affecting the dimensional accuracy, performance and quality of castings, surface hardness and low sand core strength, and affect the precise size of the sand core, etc., to improve the system Reliability, guaranteed dimensional accuracy and simplified system configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

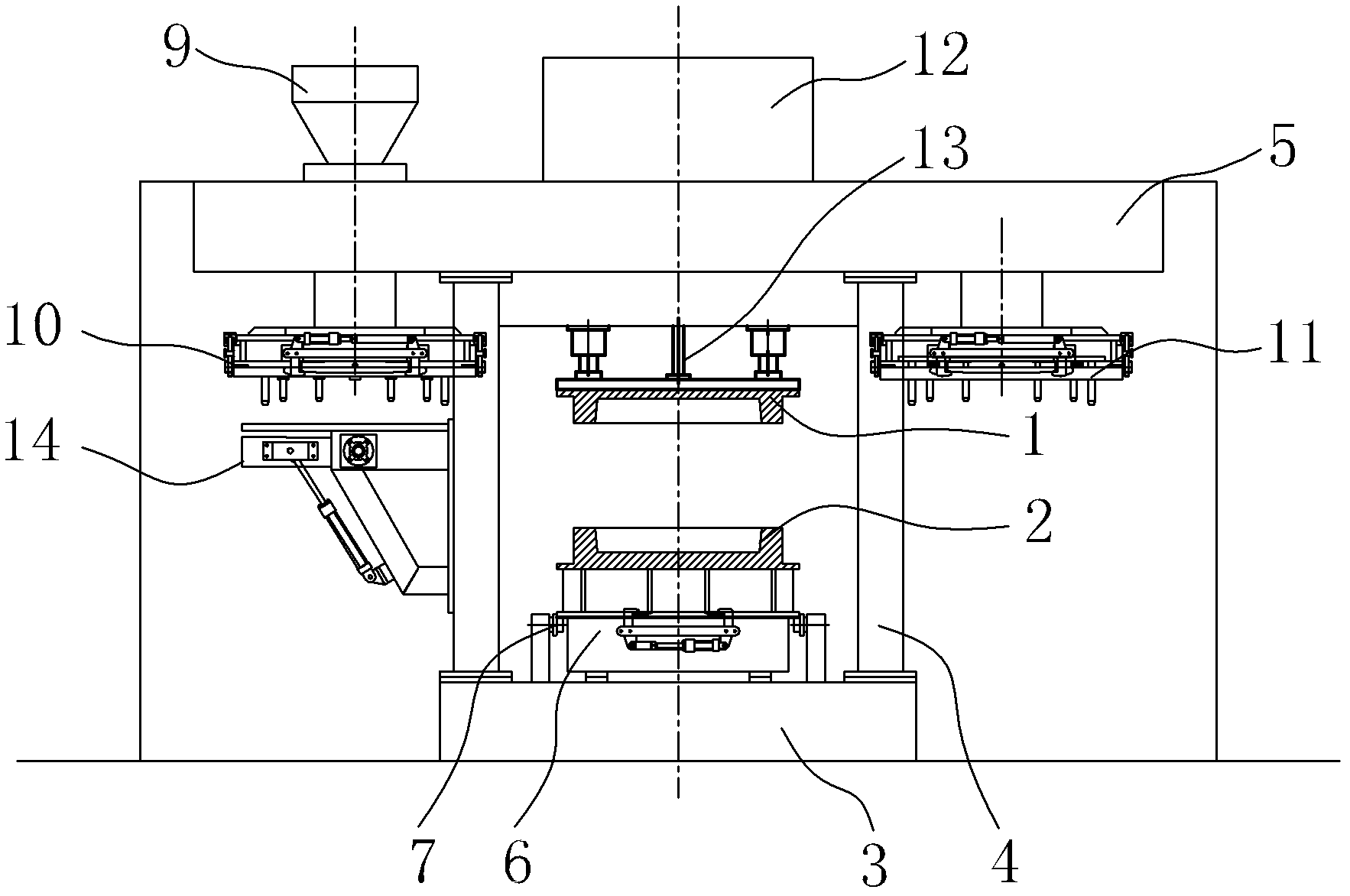

[0031] like figure 1 As shown, an online core-making device includes a frame, an upper mold 1 fixedly arranged on the frame, a lower mold 2 matched with the upper mold 1, and a sand-shooting and blowing assembly. Specifically:

[0032] The frame includes a base 3 , a column 4 arranged on the base 3 and an upper frame 5 supported on the column 4 . The base 3 is provided with a workbench 6 and a motorized raceway 7, and the workbench 6 is provided with a lower core.

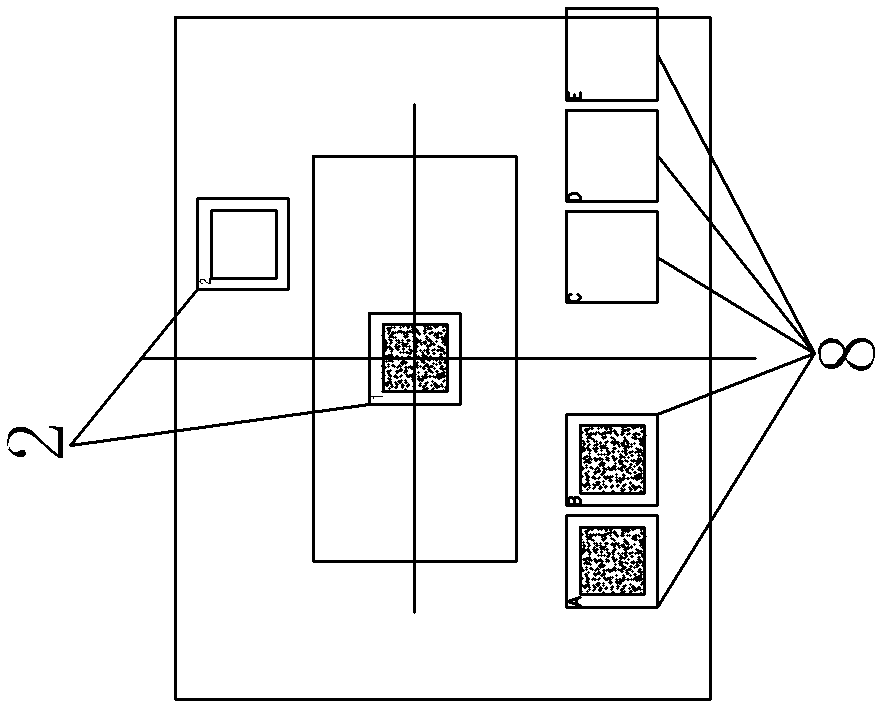

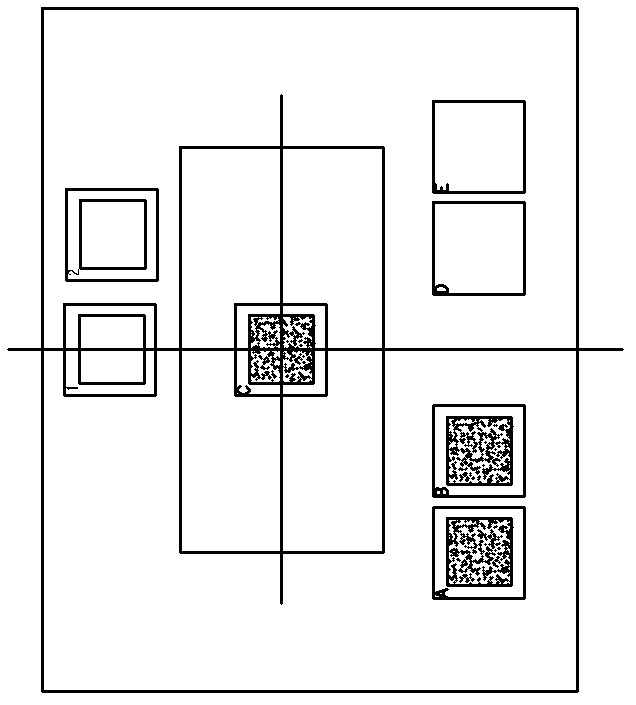

[0033] The frame is movably provided with several pallets 8, the lower mold 2 and the pallets 8 are transported through the motorized raceway 7, and the workbench 6 is used to carry the working pressure during sand shooting and air blowing.

[0034] The sand-shooting and blowing assembly includes a sand bucket 9, a jet head 10 communicating with the sand bucket 9, a blowing cover 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com