Flange end face machining device

A technology of end face processing and flanges, which is applied in the field of flange end face processing devices, can solve the problems of high construction cost, long time-consuming flange assembly and disassembly and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

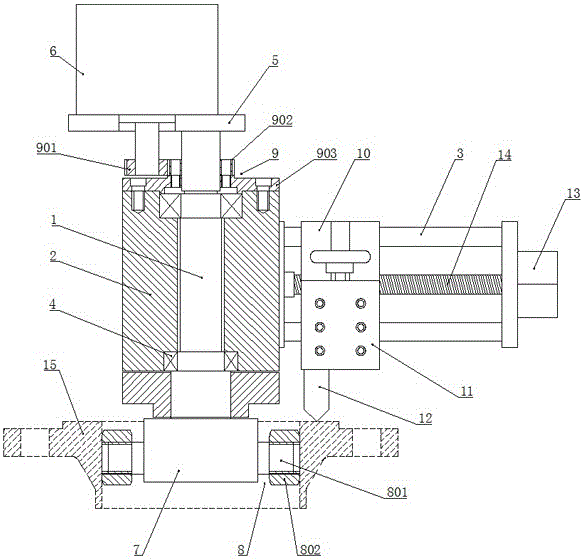

[0013] exist figure 1 Among them, a flange end face processing device includes a fixed shaft 1 , a rotating sleeve 2 and a parallel guide rail 3 . Wherein, the rotating sleeve 2 is rotatably arranged on the fixed shaft 1 via the rotating supporting member 4 .

[0014] Such as figure 1 As shown, in this embodiment, a deep groove ball bearing and a tapered roller bearing are preferred for the rotating support member 4, the deep groove ball bearing is used to bear the radial load of the rotating sleeve 2, and the tapered roller bearing bears the radial load of the rotating sleeve 2 The radial load is used to bear the axial load of the rotating sleeve 2 at the same time. The two bearings cooperate to rotate and support the two ends of the rotating sleeve 2 on the fixed shaft 1, so that the rotating sleeve 2 can rotate with high precision, flexibility and reliability, and can effectively prevent the rotation of the sleeve 2. During the process, the "stuck" phenomenon occurs.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com