Direct carbon fuel cell reaction device

A fuel cell and reaction device technology, applied in the direction of fuel cells, fuel cell additives, fuel cell parts, etc., can solve the complex design and manufacture of direct carbon fuel cell reaction devices, increase the volume of cathode and anode cavities, and seal Material failure and other issues to achieve the effect of preventing seal failure, enhancing sensitivity and optimizing performance

Active Publication Date: 2009-01-14

TSINGHUA UNIV

View PDF0 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the battery is running, affected by heat transfer and radiation, the temperature outside the furnace of the reaction device is high, which is easy to burn or lead to failure of the sealing material. Although increasing the length of the device can avoid excessive temperature, it will also increase the size of the cathode and anode chambers. volume, so the water cooling function is very necessary

[0007] For the above reasons, the design and manufacture of direct carbon fuel cell reactors is very complicated, and it is difficult to meet the above requirements at the same time, so it is necessary to improve the research and development of direct carbon fuel cell reactors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0074] A direct carbon fuel cell reaction device, its operation process is as follows Figure 26 shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

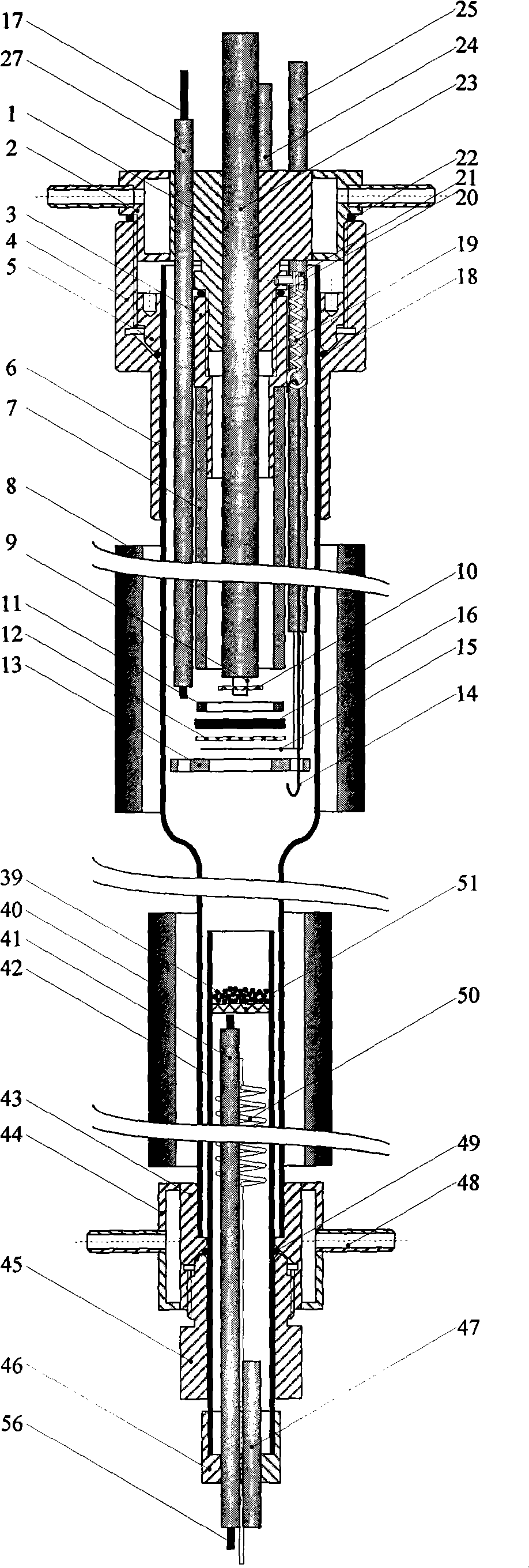

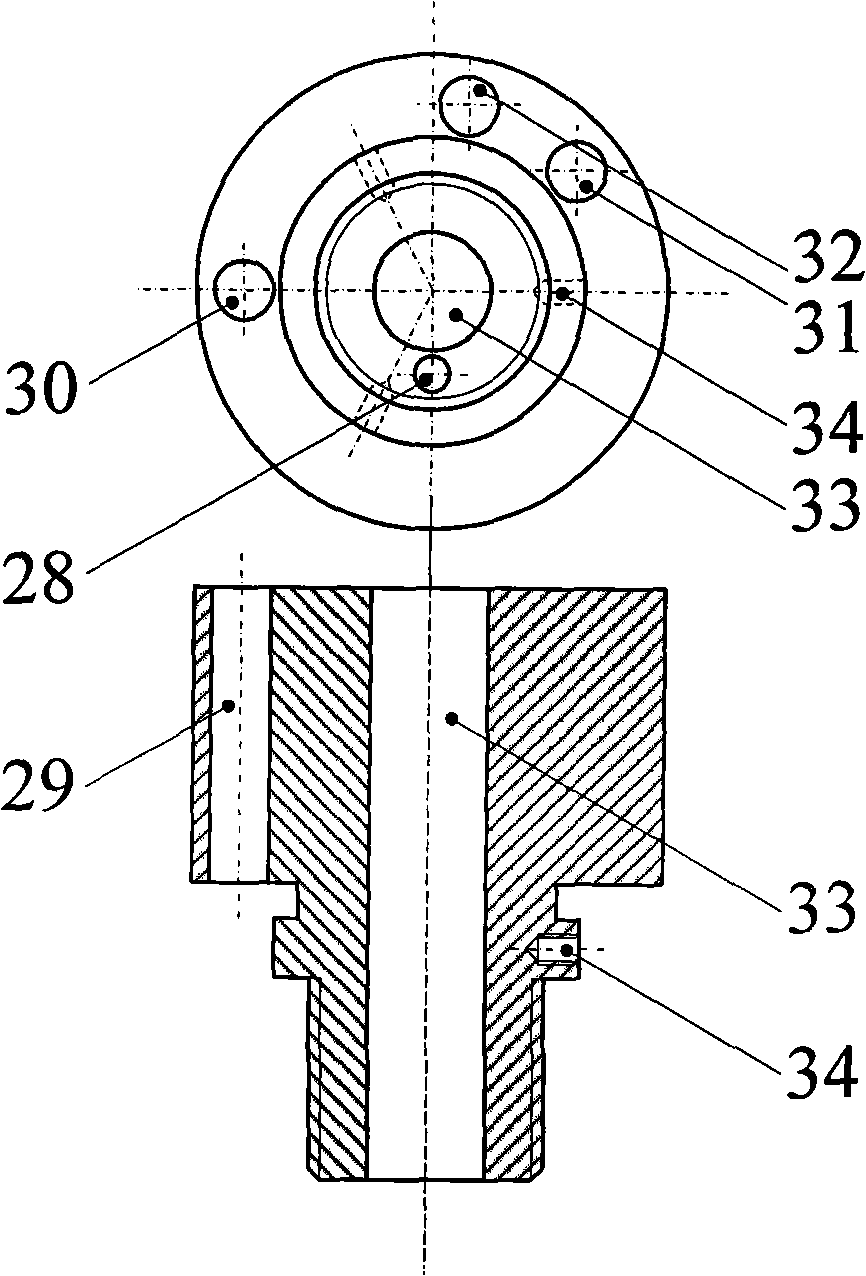

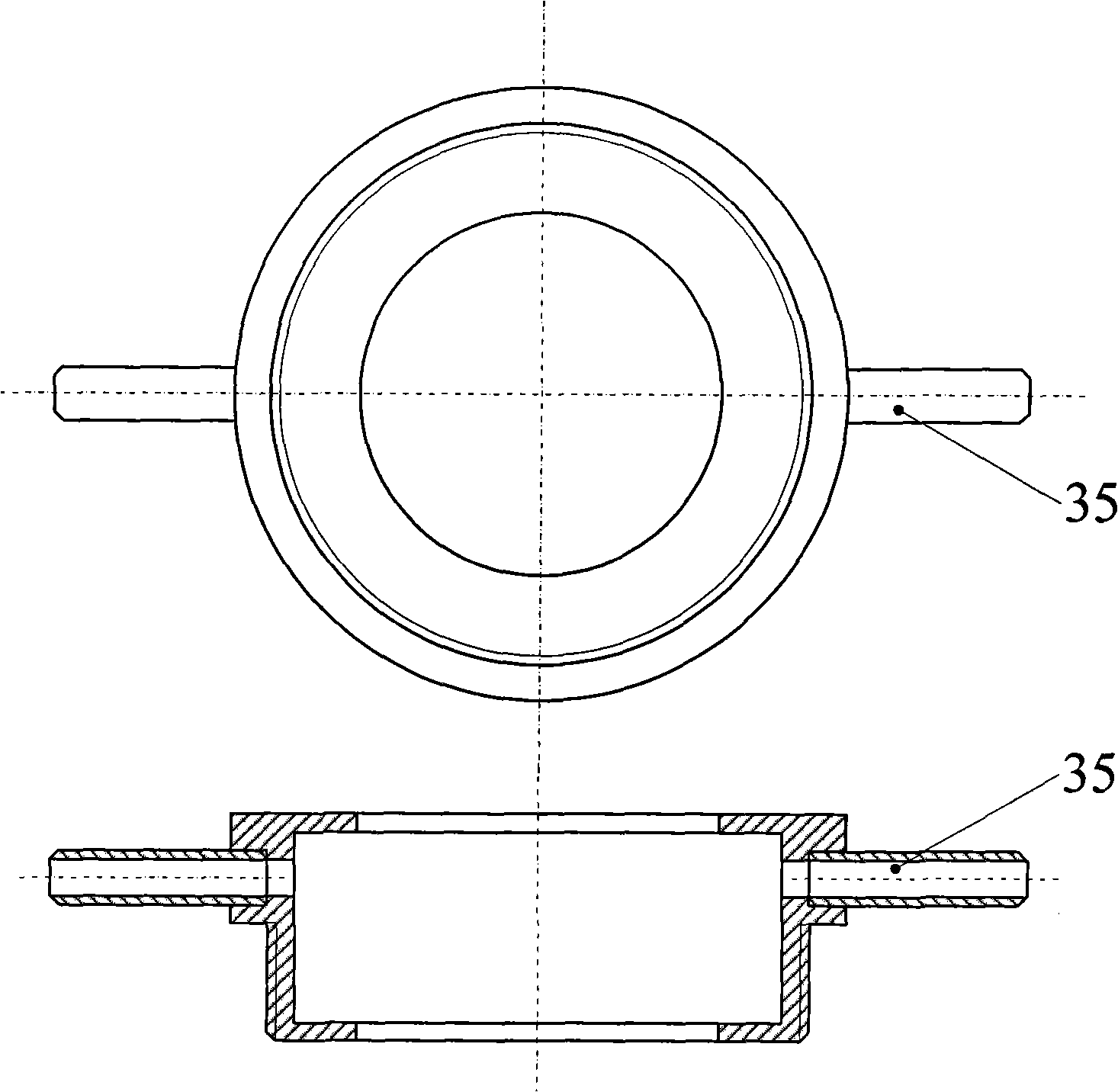

The invention provides a direct carbon fuel battery reaction device, belonging to the field of direct carbon fuel battery technique. An upper base (1) of the reaction device is coaxially arranged into a water cooling sleeve (2); the connection of the upper base and the water cooling sleeve is welded and sealed to form a water cooling chamber; an anode current collecting Pt net (12) is used for collecting current from the anode of a button-typed solid oxide fuel battery (16); two ends of an anode current collecting Pt wire (15) are respectively used as an reference electrode and a testing electrode; the temperature measuring point of a temperature measuring thermal-couple (17) and the button-typed solid oxide fuel battery (16) keep in the same height; the bottom of an anode chamber pipe (6) is inserted into the upper hole of a lower base (43); the lower surface of a quartz sand sintering plate (42) is provided with a carbon fuel thermal-couple (56); all pipes and sealing heads (46) are hermetically connected with each other. The direct carbon fuel battery reaction device of the invention solves the problem of water adding of anode chamber and the arranging of carbon fuel, realizes that the temperatures required by the running of fuel battery and the reacting of the carbon fuel are respectively controlled, avoids complex disassembly / assembly process and personnel scald, prevents the sealing invalidity and reduces the cost.

Description

technical field [0001] The invention relates to a direct carbon fuel cell reaction device, which belongs to the technical field of direct carbon fuel cells. Background technique [0002] The fuel cell can directly convert the chemical energy stored in the fuel into electrical energy without being limited by the Carnot cycle. It has the advantages of high energy conversion efficiency, cleanliness, no pollution, low noise, strong module structure, and high specific power. It is favored by countries all over the world. broad attention. [0003] Among them, the direct carbon fuel cell (Direct Carbon Fuel Cell, DCFC) is different from the fuel cell using gas or liquid fuel. The direct carbon fuel cell directly uses solid carbon as fuel. Its unique advantages are: the theoretical efficiency of the battery is higher; Carbon fuel, eliminating the need for gasification; solid carbon fuel is small in size, high in calorific value, and convenient for storage and transportation; at the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M8/02H01M8/04H01M8/06H01M8/10H01M8/0267H01M8/0276H01M8/04029H01M8/0432H01M8/0606H01M8/1007

CPCY02E60/521Y02E60/50

Inventor 蔡宁生李晨史翊翔

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com