Boxing equipment for engineering construction glass

A kind of construction and glass technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low work efficiency, labor-intensive, unstable factors, etc., achieve convenient movement, increase packing efficiency, and ensure continuous stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

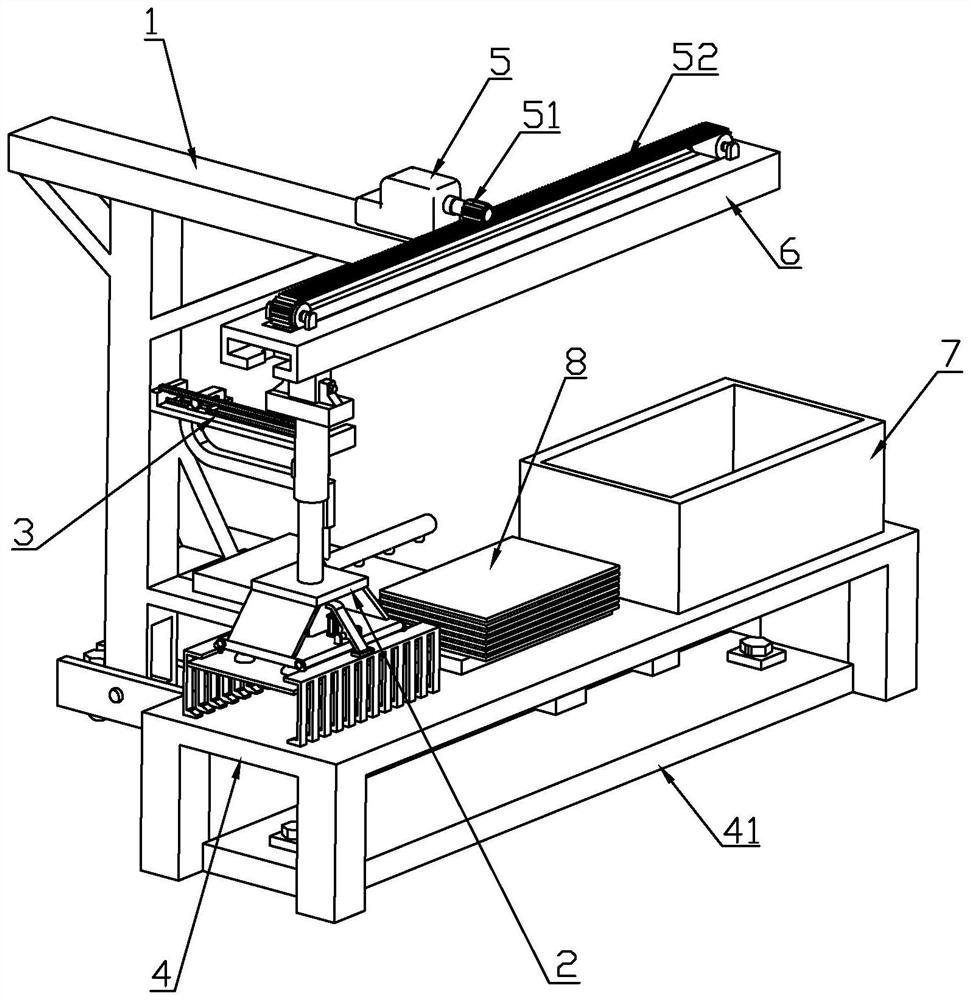

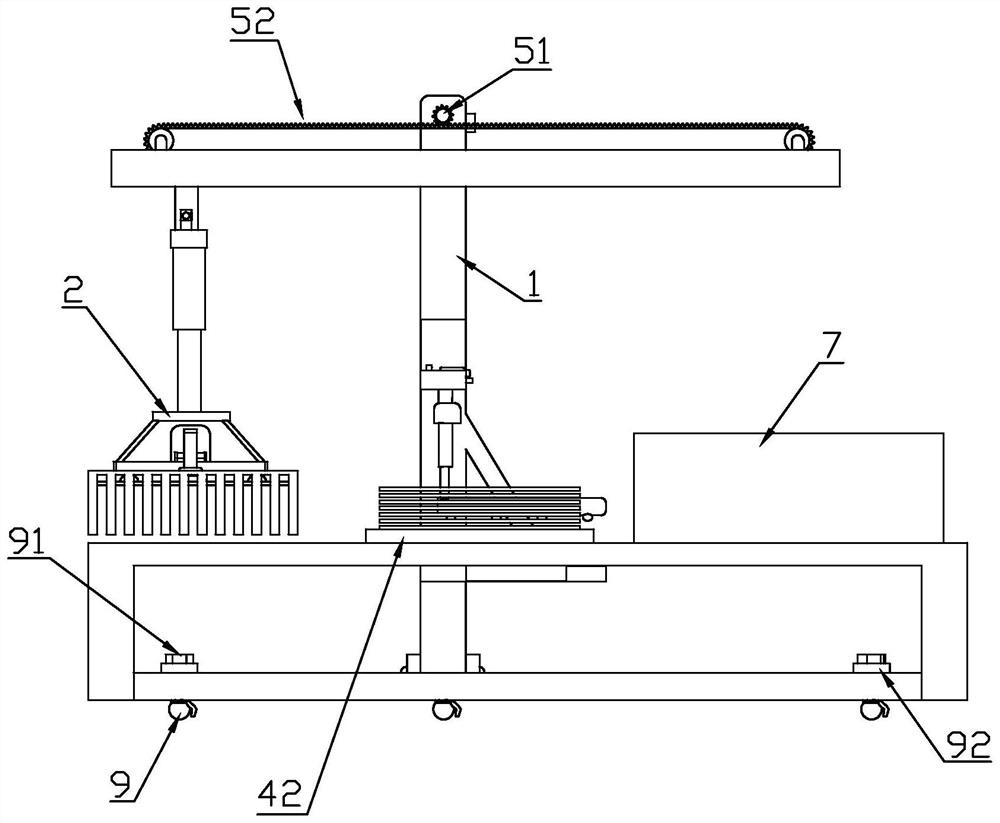

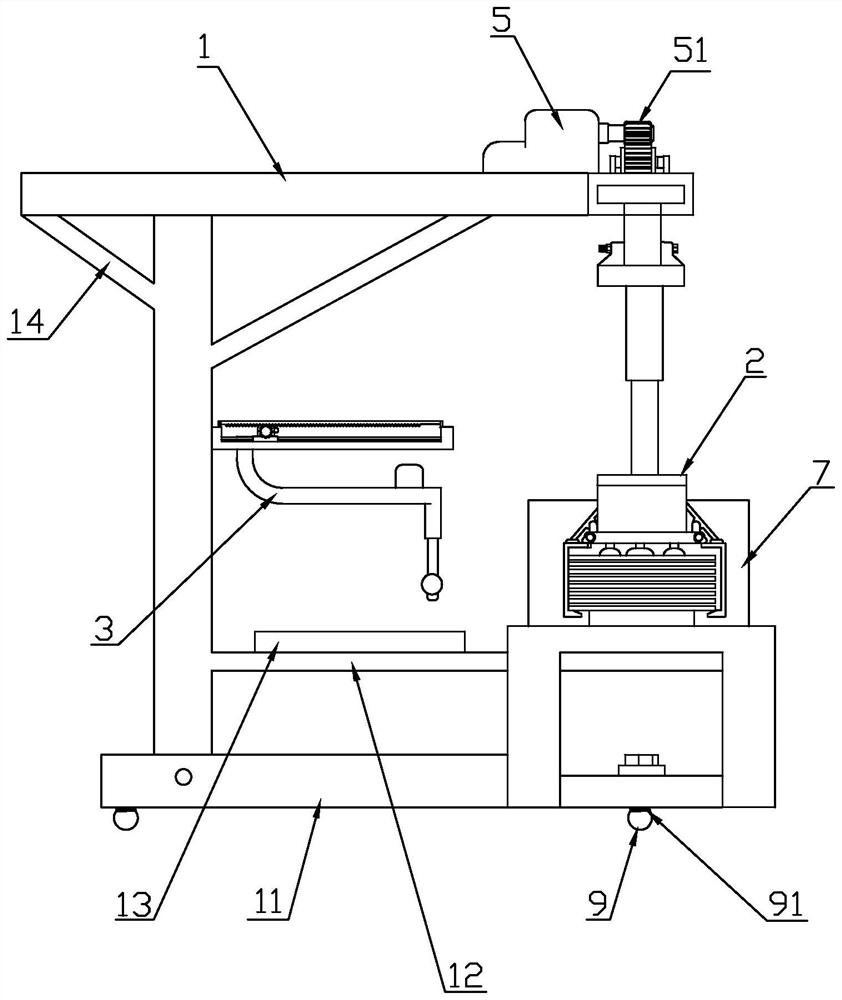

[0024] Such as Figure 1-6As shown, a kind of packing equipment for glass used in engineering and construction, including a support frame 1, a grabbing mechanism 2, a gasket conveying mechanism 3, and a supporting platform 4, and the two sides of the support frame 1 are respectively fixed with reinforcing rods arranged obliquely 14. The reinforcing rod 14 is used to increase the stability of the support frame and avoid deformation. The support frame 1 is provided with a stand 4 on one side, and the top side of the support stand 4 is provided with a grasping mechanism 2, which is used to fix the glass 8 Grabbing and moving, one side of the grabbing mechanism 2 is provided with a gasket delivery mechanism 3, the gasket delivery mechanism 3 is fixedly connected to the side of the support frame 1, and the top of the grabbing mechanism 2 is slidingly connected with a T-shaped Slot plate 6, the T-shaped slot plate 6 is a structure in which a T-shaped chute 34 is arranged on the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com