Preparation technology of pectin in sunflower disk and used continuous microwave system device

A sunflower plate and microwave technology is applied in the fields of extracting pectin from sunflower plates and pectin extraction and preparation, which can solve the problems of low pectin quality, inability to realize industrialized production, low pectin extraction rate, etc. The effect of pollution, realization of material reuse, and reduction of waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: the extraction of pectin in the sunflower dish

[0035] The specific extraction method of pectin in sunflower dish is as follows.

[0036] (1) Pretreatment of sunflower trays: dry the sunflower trays naturally, crush the sunflower trays with a moisture content of less than 8% with a grinder, and sieve them through a 60-mesh sieve;

[0037] (2) Enzyme inactivation: Inactivate sunflower powder in boiling water for 3 minutes, filter the filtrate with 400-mesh gauze, wash the filter residue with 75°C water and keep it warm for 30 minutes;

[0038] (3) Blending: filter the sunflower dish solution treated in step (2), add distilled water to the filter residue at a solid-liquid ratio of 1:25 (solid-liquid ratio unit?), and adjust the pH to 2 with hydrochloric acid;

[0039] (4) Continuous microwave treatment: put the sunflower dish liquid prepared in step (3) into the self-set microwave continuous extraction system device, load the sunflower dish liq...

Embodiment 2

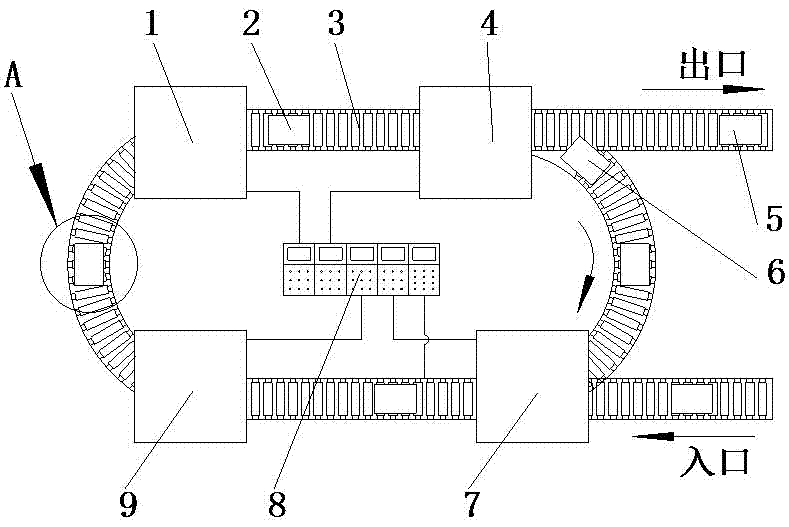

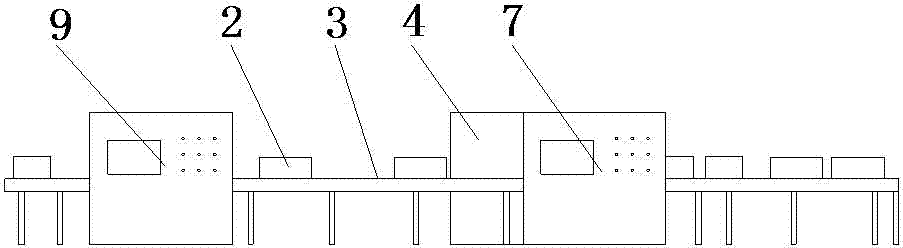

[0043] Embodiment 2: microwave continuous extraction system device

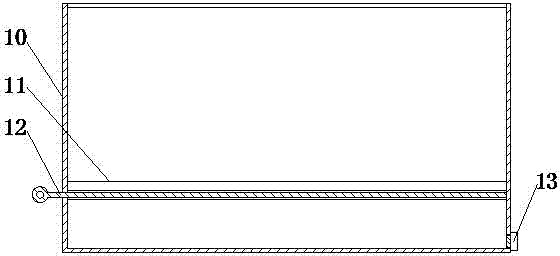

[0044] See attached figure 1 to attach image 3 , the microwave continuous extraction system device consists of a material box (2, 5, 6), a conveyor belt (3), a microwave extraction chamber (1, 4, 7, 9), and a console (8) connected in sequence, wherein the material The box (2, 5, 6) is composed of a material box body (10), a filter screen (11), a partition layer (12), and a drain plug (13); the partition layer (12) is a drawer-type structure, It is used to store the liquid in the material in the material box body (10) through the filter screen (11) for convenient pulling; the filter screen (11) is located on the partition layer (12), and the partition layer (12) is connected with the material box Close contact between the casings (10).

[0045] In the microwave continuous extraction system device provided by the present invention, the partition layer (12) is placed at one-third of the material box body (...

Embodiment 3

[0054] Embodiment 3: Pectin in sunflower plate adopts acid extraction process optimization test

[0055] 1. Sunflower plate pectin preparation process: sunflower plate→crushing→sieving→enzyme inactivation→filtering→decolorization→filtering→water bath→filtering→alcohol precipitation→drying.

[0056] The sunflower disc is crushed evenly with a miniature universal grinder, sieved with a 60-mesh sieve, inactivated in boiling water for 3 minutes, filtered with a 400-mesh gauze to remove the filtrate, and the filter residue is washed with 75°C water and kept for 30 minutes; filter, and add distilled water to the filter residue according to a certain ratio of material to liquid , adjusted to a certain pH, at a certain temperature, leaching for a certain period of time; after taking it out, filter the filter residue, perform secondary extraction on the filter residue, combine the two filtrates, adjust the extract to pH = 3.5 with dilute ammonia water, and use 95% ethanol for pectin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com