Device of leaching and electrokinetically remediating chromium slag stacking place by nanometer zero-valent iron and nickel

A nano-zero-valent iron and electrodynamic technology is applied in the field of devices for remediating chromium slag-contaminated soil, which can solve the problems of great harm and high hexavalent chromium content, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

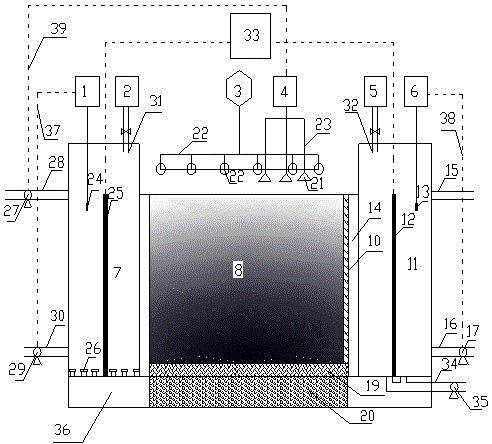

[0047] A device for electrokinetic repairing of chromium slag piles by nanometer zero-valent iron-nickel leaching. The cathode and anode are electrodes made of graphite plates, which are connected to the negative and positive electrodes of the power supply respectively; the volume ratio of the cathode and anode chambers to the soil chamber is Both are 1:3; the chromium concentration is 150 mg / kg taken from the soil of the chromium slag stacking site; the voltage is 30 V, the anolyte is citric acid-sodium citrate buffer solution with pH=3, and the cathode is 3 mol / L FeCl 3 solution, the concentration of the eluent was 3 g / L, and the experiment period was 144 h. The heavy metal content in the soil sample was determined by flame atomic absorption; the removal rate of chromium was 85.6%.

Embodiment 2

[0049] A device for electrokinetic repairing of chromium slag piles by nanometer zero-valent iron-nickel leaching. The cathode and anode are electrodes made of graphite plates, which are connected to the negative and positive electrodes of the power supply respectively; the volume ratio of the cathode and anode chambers to the soil chamber is Both are 1:3; the chromium concentration is 150 mg / kg taken from the soil of the chromium slag stacking site; the voltage is 30 V, the anolyte is citric acid-sodium citrate buffer solution with pH=3, and the cathode is 5 mol / L FeCl 3 solution, the concentration of the eluent was 3 g / L, and the experiment period was 144 hours. The heavy metal content in the soil sample was determined by flame atomic absorption; the removal rate of chromium was 86.7%.

Embodiment 3

[0051] A device for electrokinetic repairing of chromium slag piles by nanometer zero-valent iron-nickel leaching. The cathode and anode are electrodes made of graphite plates, which are connected to the negative and positive electrodes of the power supply respectively; the volume ratio of the cathode and anode chambers to the soil chamber is Both are 1:3; the chromium concentration is 150 mg / kg taken from the soil of the chromium slag stacking site; the voltage is 30 V, the anolyte is citric acid-sodium citrate buffer solution with pH=3, and the cathode is 3 mol / Fe of L 2 (SO 4 ) 3 solution, the concentration of the eluent was 3 g / L, and the experiment period was 144 hours. The heavy metal content in the soil sample was determined by flame atomic absorption method; the removal rate of chromium was 87.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrolyte | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com