Method for processing waste water generated by extracting copper oxide from acidic corrosion waste fluid

A technology for acid etching waste liquid and treatment method, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , the problem of high cost, to reduce the content of ammonia nitrogen, a large amount of treatment in a short time, reduce the effect of COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

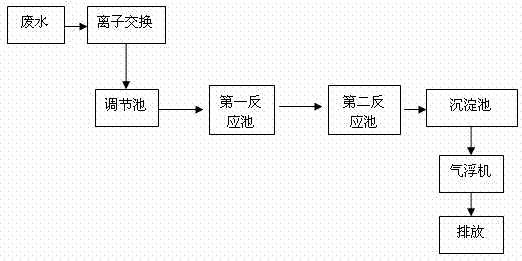

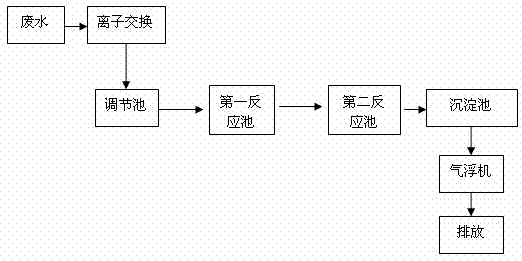

Image

Examples

Embodiment 1

[0053] In Example 1, the waste water after extracting copper oxide with the acidic etching waste liquid is prepared by the following method:

[0054] (1) The acidic etching waste liquid is put into the impurity removal liquid storage tank after impurity removal.

[0055] (2) Add 5m to the alkali distribution tank 3 Water, while stirring, add 2.5m 3 The mass concentration is 50% sodium hydroxide solution and 800kg of mixed powder of sodium carbonate and sodium bicarbonate. After the solid is dissolved, put the lye into the lye storage tank.

[0056] (3) Pour 3m into the copper oxide synthesis kettle 3 Clean water is preheated to 85°C with stirring, and the preheated acidic etching waste liquid and lye are poured into it respectively to produce copper oxide. During the reaction process, the reaction temperature was controlled at 75-85°C, the pH was between 7.0-7.5, and the stirring speed was 40r / min. Obtain copper oxide and waste water.

[0057] The composition of described...

Embodiment 2

[0067] Compared with Example 1, under the constant situation of all dosages and reaction conditions, adding available chlorine content is 62.5kg of sodium hypochlorite solution of 8%, and the wastewater index after treatment is as follows:

[0068] pH Copper content (mg / L) Nickel content (mg / L) Lead content (mg / L) Chromium content (mg / L) Ammonia nitrogen content (mg / L) Chlorine content (mg / L) COD content (mg / L) Step (1) processing 8.8 1.2 6.6 1.4 1.2 125 0 92 Step (4) processing 8.5 0.1 0.6 0.1 0.3 5.2 27.4 60

Embodiment 3

[0070] Compared with Example 1, under the constant situation of all dosages and reaction conditions, adding available chlorine content is 8% sodium hypochlorite solution 100.0kg, and the wastewater index after treatment is as follows:

[0071] pH Copper content (mg / L) Nickel content (mg / L) Lead content (mg / L) Chromium content (mg / L) Ammonia nitrogen content (mg / L) Chlorine content (mg / L) COD content (mg / L) Step (1) processing 8.8 1.2 6.6 1.4 1.2 125 0 92 Step (4) processing 8.4 0.1 0.6 0.1 0.3 1.2 11.0 58

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com