Magnetic flocculation reactor

A reactor and magnetic flocculation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, magnetic field/electric field water/sewage treatment, etc. Problems such as poor adaptability to water volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

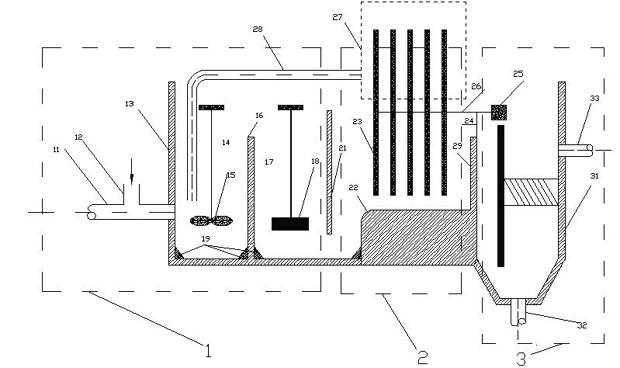

[0012] Such as figure 1 As shown, the magnetic flocculation reactor is laterally divided into a coagulation reaction zone 1, a magnetic separation zone 2 and a precipitation zone 3, wherein the coagulation reaction zone 1 and the magnetic separation zone 2 are both square structures, and the precipitation zone 3 is a circular structure. The reactor width and height are the same.

[0013] The coagulation reaction zone 1 includes a water inlet pipe 11 , a flocculant feeding port 12 , a fast stirring zone 14 and a slow stirring zone 17 . The water inlet pipe 11 is located at one-third of the bottom of the outer wall 13 of the reactor, and is fed by a high-pressure water pump. One side of the water inlet pipe 11 is provided with a flocculant dosing port 12 for adding magnetic seed composite flocculants. Raw water first enters the fast stirring zone 14 after adding the magnetic seed composite flocculant, and is fully mixed under the fast stirring of the elliptical fast stirring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com