Ammonia oxidizing denitration process and reaction apparatus

A reaction device and denitrification technology, applied in the field of flue gas denitrification, can solve the problems of high flue gas temperature, unfavorable resource recycling, and high process cost, and achieve the advantages of increasing ammonium nitrate content, improving reusability, and efficient denitrification treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

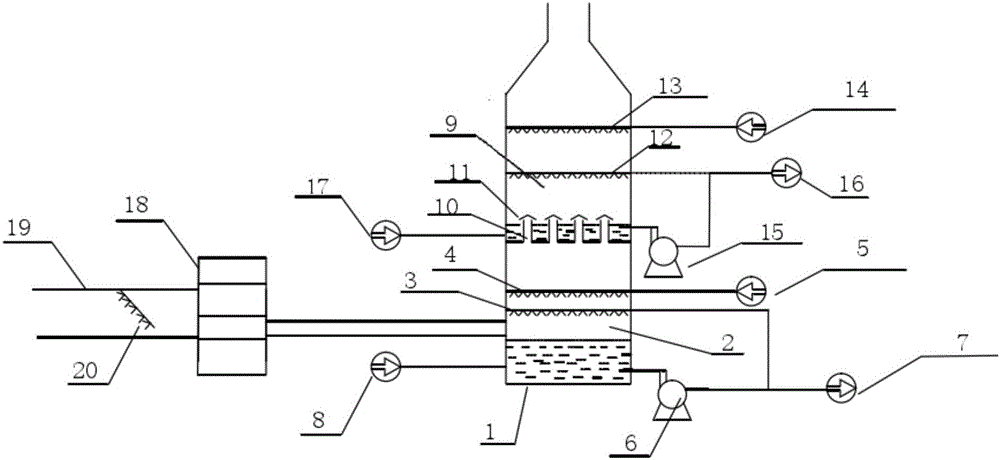

[0030] This embodiment relates to the evaluation of the denitrification efficiency of the ammonia oxidation denitrification process described in the present invention. The following embodiments are all in figure 1 in the reaction device.

Embodiment 11

[0032] The flue gas after desulfurization and dust removal is passed into the flue gas input pipeline of the reaction device, and the NO content in the flue gas passed through is tested to be 300mg / m 3 , spray ozone into the direction of 90 degrees with the flow direction of the flue gas through the ozone spray gun, the amount of ozone added is 0.6 times the molar amount of NO in the flue gas, the flue gas added with ozone stays in the static mixer for 6s, and then Enter the first-level absorption chamber of the absorption tower, and spray the first-level absorption liquid with a pH value of 8 and a mixed salt solution of ammonia water and ammonium nitrate in the first-level absorption room, and circulate the first-level absorption liquid through the primary circulation pump. Spray to form a primary absorption liquid spray layer with a height of 2 to 3 meters. During the circulating spraying process, detect the ammonium nitrate concentration of the primary absorption liquid. Wh...

Embodiment 12

[0035] The flue gas after desulfurization and dust removal is passed into the flue gas input pipeline of the reaction device, and the NO content in the flue gas passed through is detected to be 260mg / m 3 , spray ozone into the direction of 90 degrees with the flow direction of the flue gas through the ozone spray gun, the amount of ozone added is 0.5 times the molar amount of NO in the flue gas, the flue gas added with ozone stays in the static mixer for 4s, and then Enter the primary absorption chamber of the absorption tower, and spray the primary absorption liquid with a pH value of 8.2 and a mixed salt solution of ammonia and ammonium nitrate in the primary absorption chamber, and circulate the primary absorption liquid through the primary circulation pump. Spray to form a primary absorption liquid spray layer with a height of 2 to 3 meters. During the circulating spraying process, detect the ammonium nitrate concentration of the primary absorption liquid. When it reaches 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com