Rotary enamel drying and sintering production line and production process

A rotary and production line technology, applied in the field of enamel product processing, can solve the problems of high time-consuming, high temperature loss, waste of resources, etc., and achieve the effect of compact overall structure, continuous formation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

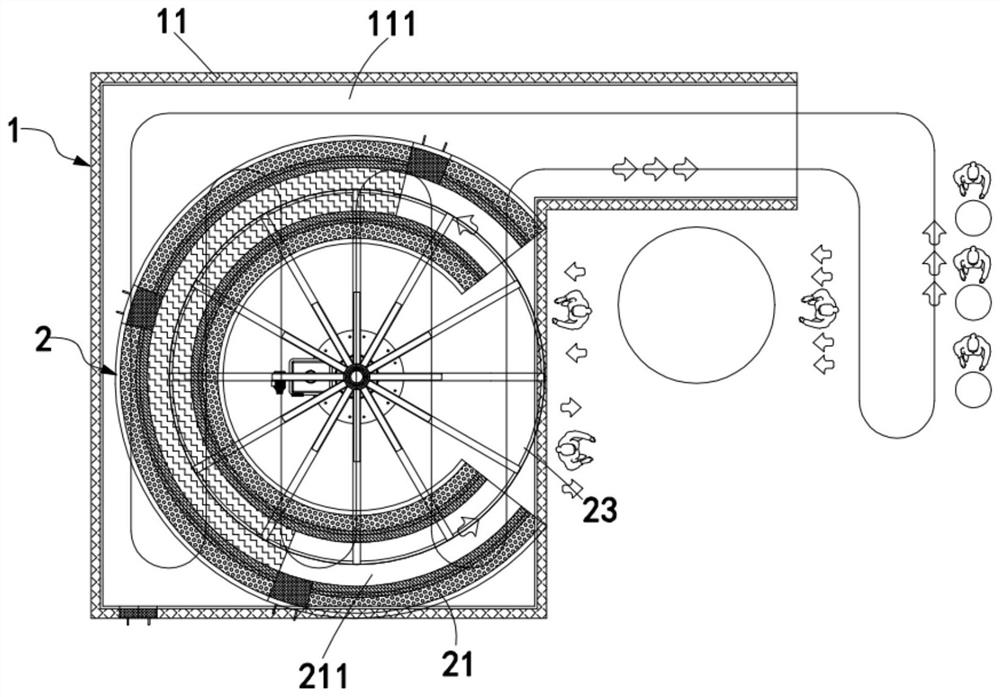

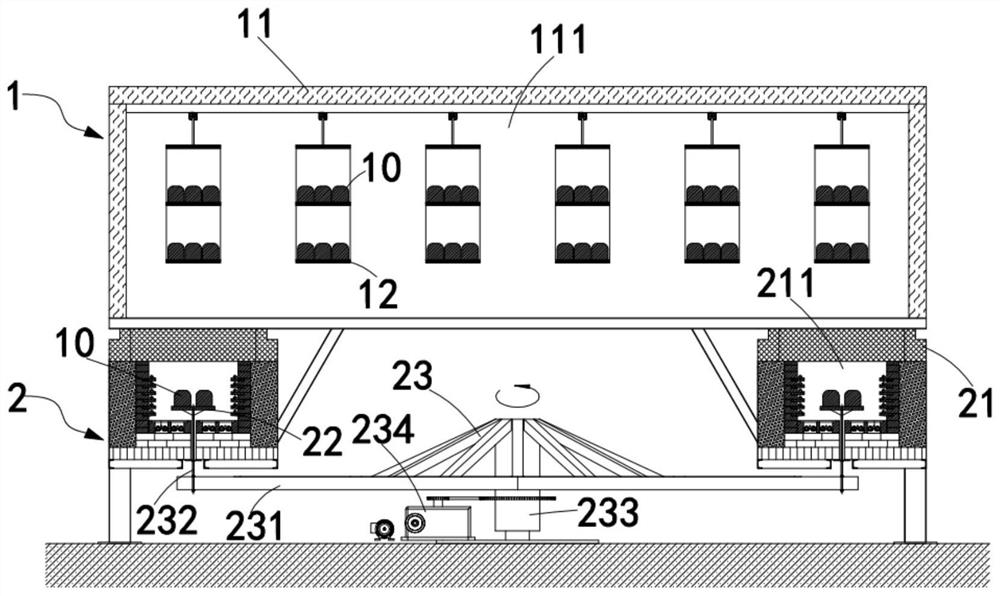

[0046] Such as Figure 1 to Figure 2As shown, a rotary enamel drying and sintering production line includes a drying device 1 and a sintering device 2, the drying device 1 is used to dry the enamel product 10, and the sintering device 2 is used to process the The enamel product 10 dried by the drying device 1 is subjected to sintering treatment, and the drying device 1 is located directly above the sintering device 2;

[0047] The drying device 1 includes a drying furnace body 11 and a number of drying platforms 12 that are circulated and transported in a drying furnace 111 inside the drying furnace body 11. The enamel product 10 is placed upside down on the drying furnace body 11. on platform 12;

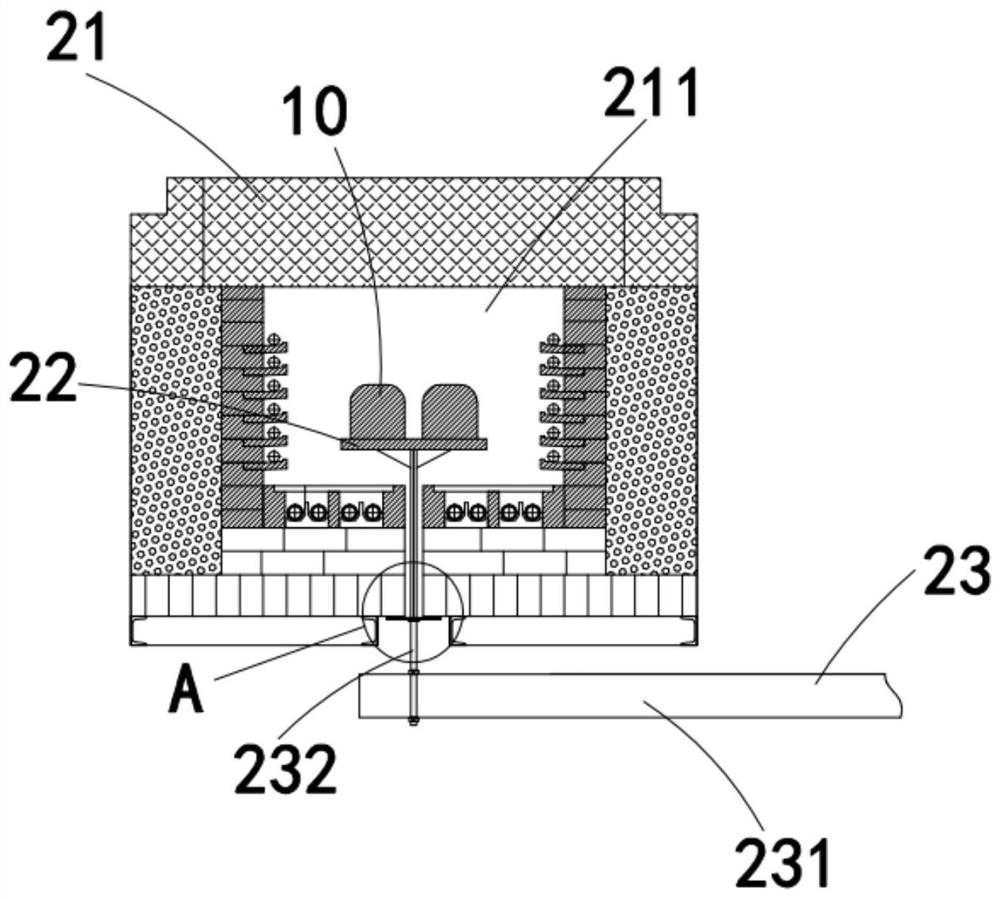

[0048] The sintering device 2 includes a sintering furnace body 21 and a number of sintering platforms 22 that are circulated and transported in a sintering furnace 211 inside the sintering furnace body 21. The sintering furnace 211 inside the sintering furnace body 21 is arranged...

Embodiment 2

[0067] Such as Figure 8 As shown, based on the production process of a rotary enamel drying and sintering production line described in Embodiment 1, it includes the following working steps:

[0068] Step 1, drying and loading, loading the enamel product 10 on the drying platform 12 located at the feeding section 132, and placing the enamel product 10 upside down on the drying platform 12;

[0069] Step 2, drying treatment, the drying platform 12 after loading is transferred to the drying section 131 located in the drying furnace body 11, and the enamel products 10 on the drying platform 12 are heated for drying treatment;

[0070] Step 3, drying and unloading. After the enamel product 10 is dried, it is transferred to the unloading section 133 for unloading;

[0071] Step 4, transit conveying, the unloaded enamel product 10 is placed on the turntable 3, and transferred to the input end 215 of the sintering device 2 on the opposite side of the feeding section 133 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com