A method and device for drying radioactive waste ion exchange resin in a microwave barrel

A technology of ion exchange resin and radioactive waste, which is applied in the direction of heating devices, drying solid materials, heating to dry solid materials, etc., can solve the problems of waste ion exchange resin denaturation, block heat conduction, etc., to prevent secondary pollution and harm personnel Potential to inflict damage, strong penetrating power, and short processing time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

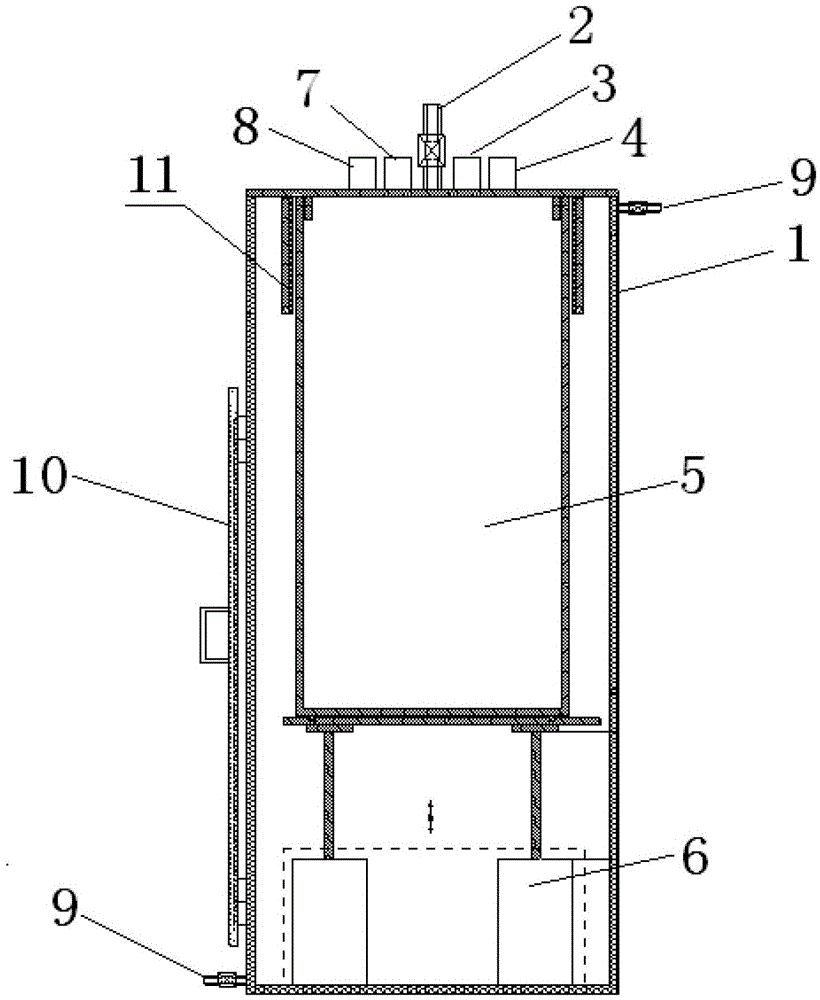

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

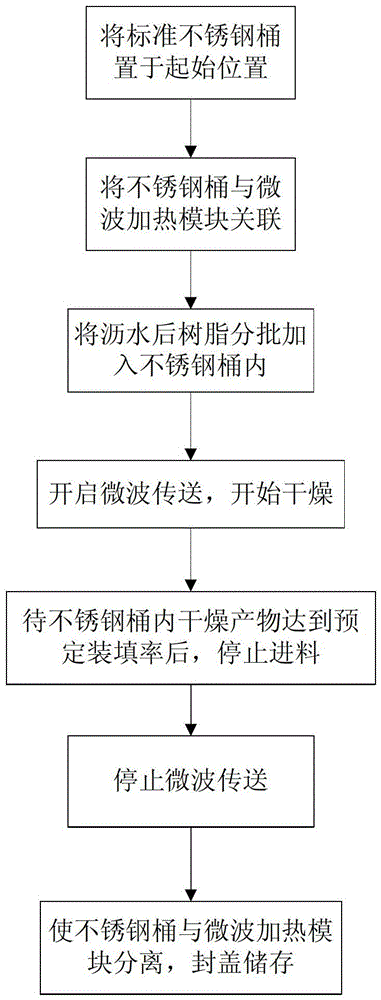

[0030] like figure 1 As shown, a method for drying radioactive waste ion exchange resin in a microwave barrel provided by the present invention includes the following steps:

[0031] (I) Draining the radioactive waste ion exchange resin.

[0032] During the specific operation, the radioactive waste ion exchange resin temporarily stored at the user site is usually transported to a stainless steel barrel (usually a 200L standard stainless steel barrel is used, and the stainless steel barrels described in the examples all refer to a 200L standard stainless steel barrel); The radioactive waste ion exchange resin at the user's site is usually transported from the resin storage tank into the drainage metering device by means of hydraulic transportation, and then the water is drained by air pressure.

[0033] (II) Transfer the drained radioactive wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com